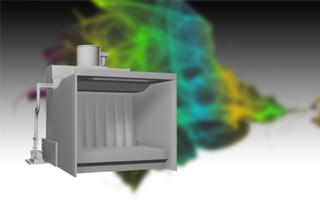

OIL BOOTH Dedicated to coating(Use oil as flushing liquid)

Long product life, Low noise, and Dedicated to coating booth

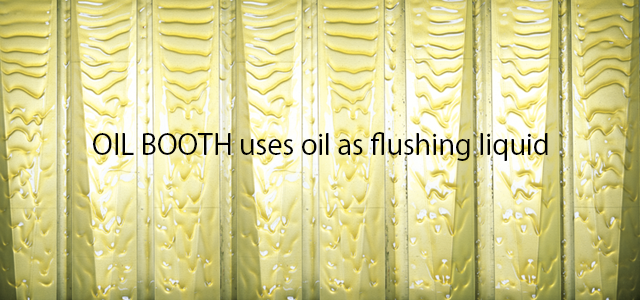

Flushing oil can be used semi-permanently.

A coating booth that can be used for a long time. The oil does not rot, so it can be used for a long time. It is quiet and you can talk in front of the booth.

A booth dedicated to coating that uses oil as the flushing liquid. OIL BOOTH. The noise is low as you can talk in front of the booth, and the workers are safe and not be tired. No need for wastewater treatment equipment unlike water booth. Oil can be used semi-permanently by removing paint sludge on a regular basis. Japan's first oil booth for coating is TAKUBO Engineering's equipment.

Lineup

-

OIL BOOTH

Economical Mist Adsorbing Booth Using Oil

Booth

OIL BOOTH makes possible a work environment that cannot be achieved using conventional water cleaning booths. It also reduces pollution and contributes to improved quality. OIL BOOTH solves a variety of problems affecting the coating workplace.

Dust elimination effectiveness is 95%. Quiet 63 dB operation means you can hold conversations or discussions even right in front of the booth.

A constant inward flow of air at the opening stops stray air currents and prevents mist overspray from getting on work surfaces. This substantially reduces coating defects and improves productivity.

Mist overspray is collected by oil, so there is no danger of mist escaping from the booth. This provides a cleaner work environment. -

OIL BOOTH for manual TB36-23BSOIL BOOTH

Example of manual type of OIL BOOTH for coating

Booth

OIL BOOTH for manual is provided with dividers to improve workability. In addition, because of its high quietness, it has excellent performance that allows workers to spray without stress.

-

OIL BOOTH for manual TB42-20BOIL BOOTH

Example of manual type of OIL BOOTH for coating

Booth

Manual type of OIL BOOTH corresponding to two workers. Long service life with low noise, use the oil in the cleaning solution, and its friendly booth to the environment.

-

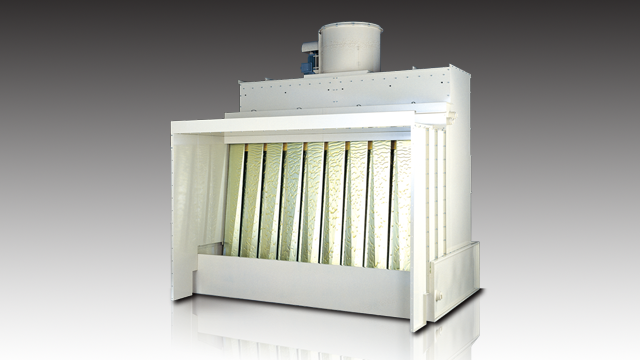

Standard Product, TB-3623BOIL BOOTH

Booth

OIL BOOTH for Coating is flexibly available for various coating articles, article-sizes and workability. It is suitable to over-spray collection for coating robot and also good for manual-spraying.

What is coating booth?

Overspray (the paint that does not adhere to the object or workpiece) always occurs during coating work in coating or painting production. Equipment must be installed to capture / exhaust this overspray mist (waste paint). Equipment / facility with this overspray collection function is called a coating booth.

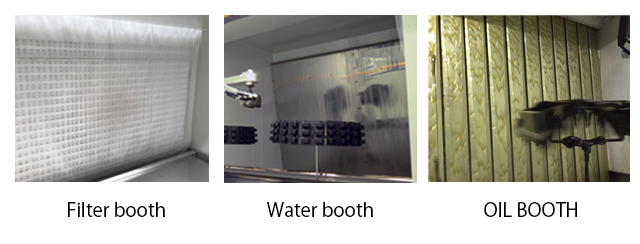

There are 3 types. There is a filter booth, a water booth (pump / pumpless), and an oil booth. The choice of booth depends on the type of paint, the amount of paint used, and the cost.

Coating Booth types

Three types of coating booth are used. Usage is properly according to the purpose of usage and cost. The choice of booth type to use depends on the intended use and cost.

Main features of the coating booth.

- Filter booth: For test coating and extremely small amount of coating work. Inexpensive. Easy to set.

- Water booth: Water is used as the flushing liquid. Relatively cheap. But have a high noise to produce a high suction effect. Rust. Medium term use.

- Oil booth: Oil is used as the flushing liquid. Move the spray in parallel and collect it with an oil curtain. Low noise that can make a conversation in front of the booth. Long term use but expensive.

The firsts OIL BOOTH in Japan from TAKUBO Engineering.

From water to oil. Oil used coating booth.

High safety.

「Does the oil burn?」「Oil remains even if the building burns!」

The flash point of the flushing liquid "TABO OIL" that used in the oil booth is about 200 ° to 250 ° or more. Because it is flame-retardant, you can work safely.

Good for economical because it can be used semi-permanently

●"TABO OIL” TABO OIL used in OIL BOOTH does not rot. Also, paint sludge collected in the oil should be removed on a regular basis.

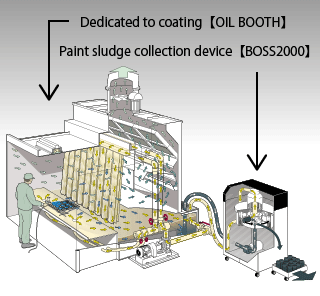

●By connecting the paint sludge collection device "BOSS2000" (option), oil and sludge are separated semi-automatically, and the procedure of paint sludge can be reduced and taken out.

In addition, industrial waste costs will be significantly reduced.

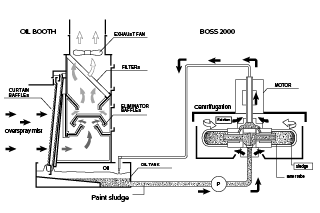

Paint sludge collection system

The overspray mist / paint collected in the oil of OIL BOOTH is pumped to the sludge collection device BOSS 2000 and separated a paint and oil by centrifugation at 1600G. The paint sludge is then solidified into small pieces, and the oil from which the sludge has been removed is returned to OIL BOOTH for reuse.

Low noise design of about 63db, work-friendly OIL BOOTH

Quiet for conversation, quiet coating booth

OIL BOOTH is about 63db of Low noise design. The no-pump booth is approximately 2/3 of about 90db. The noise is greatly reduced compared to the water booth.

The design is so quiet that you can talk in front of the booth, reducing the burden on the operator. In addition, guidance, instructions, and explanations during work are easy in front of the oil booth. In addition, the factory will be quiet.

Oil curtain collects overspray mist.

Removal of passed mist by eliminator.

OIL BOOTH has a long product life of about 30 years

Long-lasting coating booth because it is oil

The relationship between water and oil. This is long-term used booth because it does not rust. With sludge collection, filter replacement, and regular maintenance, it can be used for up to about 30 years. Hard to burn and does not rust. It is a quiet long life product booth. It was realized because it was oil.

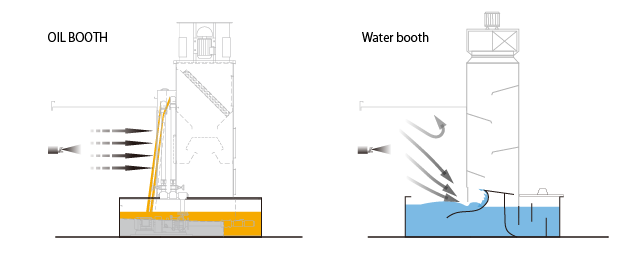

Principle of mist collection. Protect the workpiece quality, Parallel movement of airflow

OIL BOOTH does not cause turbulence of airflow

- OIL BOOTH collects the overspray in parallel. On the other hand, the water booth generates a vortex of water at the suction port at the bottom to collect the overspray, which causes turbulence and causes poor coating.

- In contrast to OIL BOOTH that collects on the surface of the booth, the water booth that collects with a whirlpool of water, generates a water flow noise of about 90 dB, which affects the stress of workers and the coating environment.

Baffle plate structure that removes mist by colliding the overspray

OIL BOOTH that collects mist on the surface puts an oil curtain on the entire surface of the baffle plate in the foreground. By flowing the oil, the overspray mist collides and the oil collects the mist. Catches the oil so that it holds the paint. Since turbulence of airflow does not occur, defects due to overspray bounce, which is one of the sources of defects, and reattachment of paint are eliminated.

Keyword of OIL BOOTH

- Collects the spray on the surface

- Parallel movement of airflow

- Low noise design

- Oil can be used semi-permanently

- Layout free

- Stress-free for operators

- Low noise and Quiet

- Sludge collection device BOSS 2000

- Can be installed in a clean room