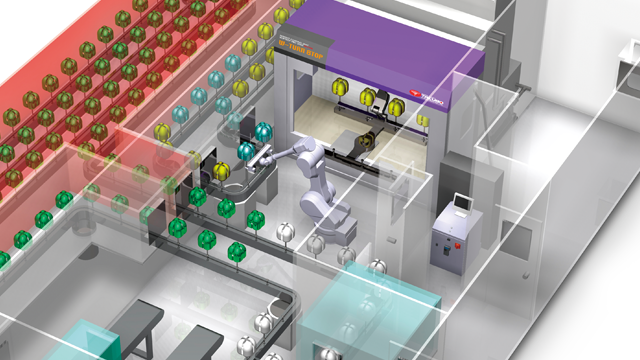

Coating Robot System for Outside Mirrors(LINE DANCER)

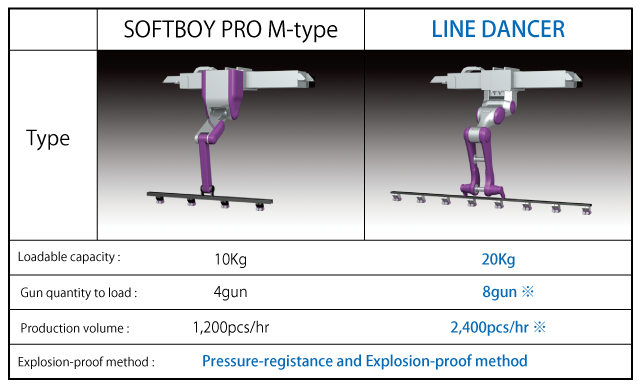

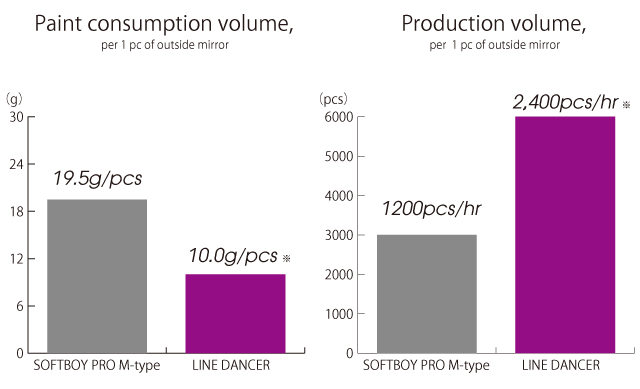

Comparison with conventional robot

※Gun quantity to load changes depending on the conditions such as production volume

2 times of loadable capacity compared with the conventional machine

- Increase of loadbale spray gun quantity improves mass-production efficiency.

- More flexible power-joint gun-pitch makes a wider range of the work size to coat.

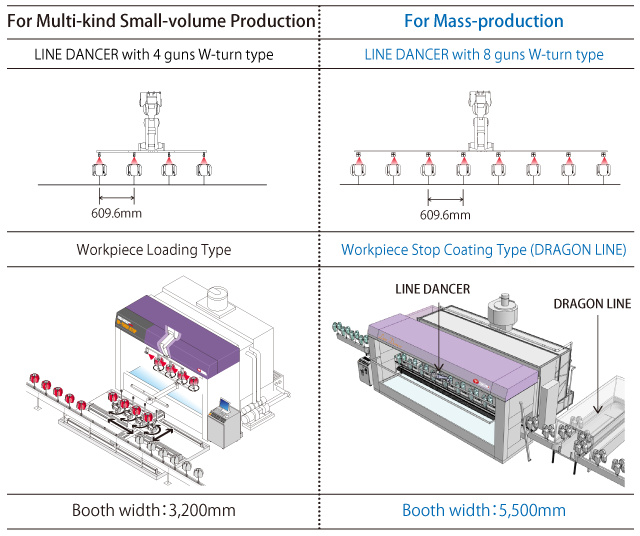

Example of Robot System

LINE DANCER W-turn type is suitable for Multi-kind production

- Line and Robot are separated so that it is a transfer loading system by handling machine.

- Conveyor-line Pollusion by over spraying is prevented.

LINE DANCER Line type is suitable for Mass-production

- Line built-in system with higher mass-production efficiency

- To reduce the booth width, DRAGON LINE, in which accumulation mechanisms are installed on the both sides of the robot, is utilized.

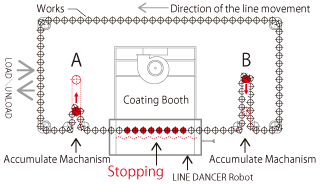

“DRAGON LINE”, High-efficiency Conveyor Line

DRAGON LINE is the conveyor line in which the accumulation mechanisms are installed on the both sides of the robot (before and after the robot on the line). The longer booth width will make the air supply volume and the energy cost larger and bigger. DRAGON LINE is able to reduce the booth width by the accumulation mechanism so that the energy cost can be saved substantially.

Structure of DRAGON LINE

- 1. When the accumulation mechanism-A starts retention, the conveyor stops in front of the booth to make a coating operation. At the same time, the accumulation mechanism-B releases retention.

- 2. After coating operation finishes, the accumulation mechanism-B starts retention and simultaneously the accumulation mechanism-A releases retention. At the same time, the conveyor in front of the booth moves at a high speed.

Increasing cost performance

- The minimum booth width even if the number of gun increases

- Decrease of the setting space

- Miniaturization of equipment and also increase of production efficiency

- Reduction of total energy cost including air supply and exhaust cost

Cost performance

Line cover for dirt prevention (Option)

Automatic opening / closing type Line cover to prevent dirt on the line by over spraying. It is quite useful as measures against dust defects because of the dirt-prevention function to keep the conveyor line clean.

Release date:July 21, 2017