Coating Robots(Coating Robot)

Dedicated coating robot

Lineup

SWAN Robot

LINE DANCER

Development Robot

Machines for Line Production

Data generation Robot

Machines for Batch/Cell Production

Small Components

Small-sized Explosion-proof AC Servo Motor

Explosion-proof AC Servo Motor Q & A

Coating Supply Systems

Gun Attachment

Sukotti Gun Series

Hose-less Gun 2018

Hose-less Gun 2018 R-11T Gun 2013

R-11T Gun 2013 R-09T Gun 2009

R-09T Gun 2009 R-08T Automatic Gun 2008

R-08T Automatic Gun 2008 R-08T Manual Gun 2008

R-08T Manual Gun 2008 R-07T Gun 2007

R-07T Gun 2007 R-05T Gun 2005

R-05T Gun 2005 R-04T Gun 2004

R-04T Gun 2004 R-00T Gun 2000

R-00T Gun 2000 R-99T-LV Gun 1999

R-99T-LV Gun 1999 R-98T Gun 1998

R-98T Gun 1998 R-92T Gun 1992

R-92T Gun 1992 R-85T2 Gun 1985

R-85T2 Gun 1985

Custom Spray Guns

Coating Robot Q&A

Spray Gun Q&A

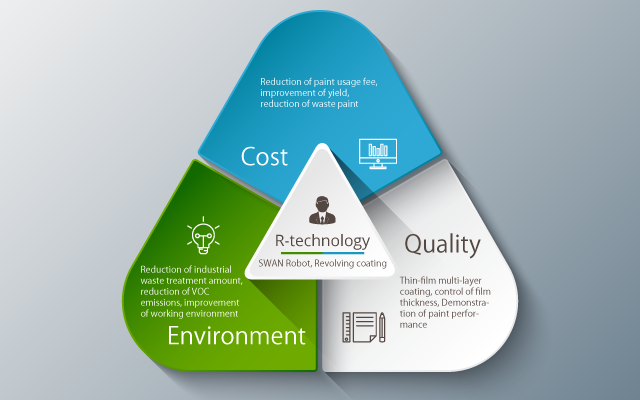

Concept of dedicated coating robot

Developing robot to make coating complete as a product

Coating robot which TAKUBO Engineering is thinking of is a robot to make coating complete as a product. To make coating data easily and to make coating complete as a product is more important than having multi-joint, number of axes and some accuracy. And to establish coating as a corporate management is very much important. "Quality, cost, environment" The coating robot that TAKUBO Engineering thinks is to solve these three themes at the same time.

Coating robot which TAKUBO Engineering is thinking of

The role of the coating robot is not whether the robot moves accurately, nor how many axes it has.

The coating robot that TAKUBO Engineering thinks is a facility for making painting into a product. In addition, we are developing robots to satisfy issues such as quality, passing grades, optimization of costs, and adaptation to the global environment.

Quality

- Realization of a coating film that demonstrates the performance of paint

- Reduction of dust, seeding, sagging, and lack of hiding

Cost

- Reduce wasteful paint consumption and finish painting with an appropriate amount of paint used

- Minimize the amount of unused paint left in the hose

- Rational process without unnecessary movement

Environment

- Reduce the amount of waste to the utmost and reduce the burden on the global environment

- Or, making reuse possible to reduce the environmental burden

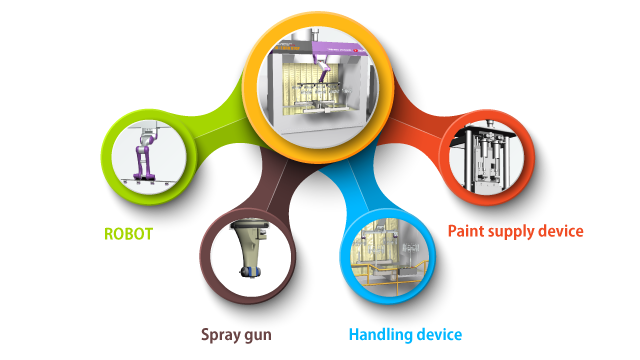

Basic equipment configuration of coating robot

Basic equipment configuration

TAKUBO Engineering's coating robots are set up with the peripherals needed for coating. Optimized peripherals have been developed so that the original revolving coating technology "R-Technology" can be used appropriately.

Integrated equipment required for coating

Option:

Oil booth and sludge collection device

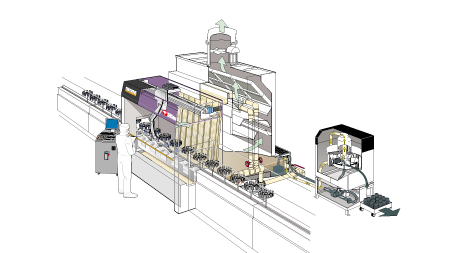

The equipment required for painting is integrated so that the pursuit of painting and productivity are extremely high.

Robots, Self-standing type and Ceiling-suspended type

The difference is the mass production effect.

The Line Dancer robot system, which integrates the robot and booth, eliminates the factors of environmental pollution and defective products caused by overspray, and realizes high-quality paint production in a clean work space and production environment.

Handling devices include W-turn with rotation mechanism, 1-station / 2-station, conveyor compatible type, etc.

The functional expandability of painting robots lies in the type of transfer device. We have a lineup of transfer devices as well as the type of robot so that we can meet various requirements such as production volume, installation space, paint used, type of work, work size, etc.

Respond to various production requirements

- Small lot multi-product production

- Mass production

- Respond to various productions such as Wet on wet or 2-coat with 2-bake

- Respond to Revolving coating and Net coating

- Respond to Batch type and Automatic type

- Automatic spraying and Hand spraying of touch-up

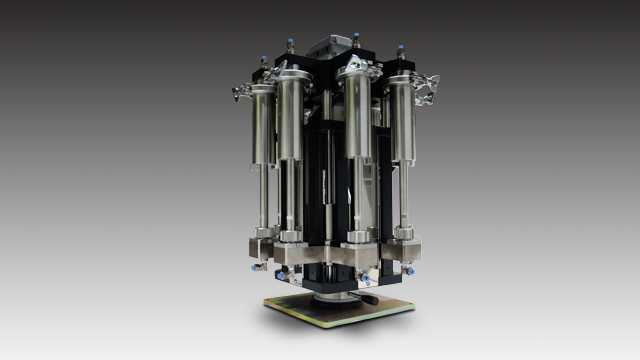

Syringe pump system, development of paint supply device

The TAKUBO Engineering painting robot is equipped with a dedicated paint supply device. The key to coating quality and cost is the paint supply device "Syringe pump" and "One cup system". In order to reduce coating costs, it is important to be able to accurately supply paint in 1cc units. Since the era of gravity-type paint cups, TAKUBO Engineering has repeatedly verified that fixed-quantity supply gear pumps and syringe pumps can be used for coating, and has arrived at the development of a dedicated syringe pump. The control of the advanced automatic gun and syringe pump, which can be controlled in 1cc units and is excellent in atomization of low pressure atomization, has realized low-cost coating of thin film multiple coating.

Syringe pump system

Based on the so-called syringe principle, an explosion-proof motor is designed and controlled for the extrusion mechanism to control the delivery of paint in 1cc units. The syringe pump is optimally linked with the software "SWANIST" developed exclusively for TAKUBO Engineering's coating robots.

One-cup system

A compact paint supply device that puts only the necessary paint in a dedicated stainless cup and sets it in a paint supply system equipped with a syringe pump function.

Pouch container type One-cup system [Proposed design]

Put the pouch container type paint pack in the special cassette and connect it to the cup connection part of the one cup system.

This is a proposal-type development product with a new delivery method for paints. A paint supply container that can be used by filling the container in the required amount.

It is a paint supply device that aims to reduce the amount of waste by eliminating unnecessary use of paint, mixing time, and cleaning work.

Dedicated spray gun

We are developing a small gun that is excellent in atomization at low pressure.

In order to achieve a high-quality thin film coating film, it was necessary to have an excellent automatic gun that could maximize the performance of the paint. The paints are becoming more sophisticated and expensive, so they cannot be wasted. In addition, it had to be easy to maintain and downsized.

The Sukotti gun series has evolved and is being developed over time.

Naming of Sukotti gun

Use only a little (“sukotti” in Japanese) paint. That is, a spray gun that uses only "a little (sukotti)" is called a Sukotti gun. Sukotti gun is a trademark of TAKUBO Engineering.

Types of coating robots

Respond to from Small-lot multi-product production to Mass production

The coating robots made by TAKUBO Engineering can be selected and system can be constructed according to the application, purpose, production plan, etc., such as dedicated painting work, mass production purpose, painting board making, painting test and small quantity high-mix coating production.

Coating robot for Mass production

- Super spindle (S-type robot)

- LINE DANCER (M-type robot)

- SWAN-C (self-standing type robot)

Batch type, Type compatible to automation

- SOFT BOY Pro W-turn type (S-type robot)

- LINE DANCER W-turn type (M-type robot)

- SWAN-Pro

Coating robot exclusively for data generation

- DATA-Pro (S-type robot, M-type robot)

- SWAN-D

Coating robot exclusively for switches, buttons, small work pieces

Super spindle SS (Suspended SCARA robot type)

Originally developed coating technology

TAKUBO Engineering's coating robots have their own coating technology. It is a revolving coating technique in which the work is rotated and the robot paints it. By rotating the work, thin film multiple coating is realized. High quality finish with a thin film. It embodies the idea of painting that prioritizes the potential of machines.

What is R-technology?

R-technology is not just a spindle coating, but a coating technology that is realized by controlling revolving coating and multiple peripheral devices. The dedicated teaching assistant software "SWANIST" controls the spray gun, robot, paint supply device, transfer device, rotary table, etc. to realize coating.

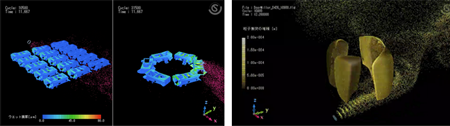

Proven revolving coating: Diversity of revolving coating and net coating

Demonstrate the superiority of revolving coating by fluid analysis

Under the same painting conditions, we verified the coating time, paint usage fee, and coating efficiency of revolving coating and net coating. Since inventing revolving coating in 1996, its advantages have been proved by modern computational fluid analysis techniques.

Various coating methods such as revolving, net and direct coating

Revolving coating is based on the logic that the spray gun waits for and paints the rotating workpiece with multiple thin film coatings. In addition, the robot supports not only revolving coating but also net coating (vertical, direct coating). You can make a coating production in detail with teaching that mixes revolving coating and direct coating.

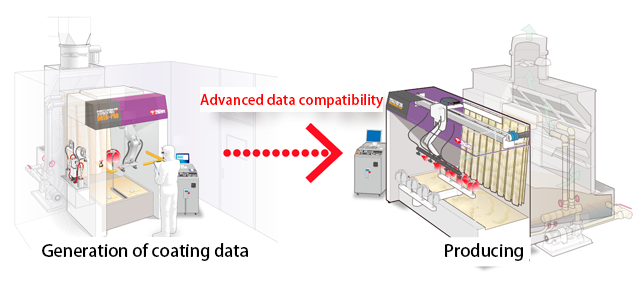

Proposal of coating production style, separation between coating data generation robot and production robot

Separate coating data generation and production

Risk in the coating production. Eliminating the risk of “decentralized production”.

TAKUBO Engineering has a lineup of robots required for coating production, divided into applications. For example, coating data generation and test robots or production robots, etc.

Strength of TAKUBO Engineering’s coating robots

A coating robot dedicated to data generation reduces risk. In the popular coating line, conditions and painting tests are also performed on this production line. There are various wastes such as energy loss, time loss, paint loss and quality loss between factories. If you create coating data using a data generation robot such as "Data Pro" or "Swan-D" for these losses, you can share the coating data between robots of the same series and reproduce the coating equally with simple adjustments.

Avoiding decentralized production risk

- Quality such as color is different for each factory

- Coating cost is different for each factory

2022.06.02

What is SWAN Robot?

What is SWAN Robot? SWAN

SWAN SWAN-C

SWAN-C SWAN-S

SWAN-S One Cup System

One Cup System SWAN-application

SWAN-application SWAN Extension Attachment

SWAN Extension Attachment LINE DANCER

LINE DANCER Double-Turn Type

Double-Turn Type Hose-less Coating Robot 2018

Hose-less Coating Robot 2018 Quick System

Quick System Hose-less Robot

Hose-less Robot BUMPER PRO

BUMPER PRO Jou-lo

Jou-lo SUPER SPINDLE 300C

SUPER SPINDLE 300C Coating Robot System for Outside Mirrors

Coating Robot System for Outside Mirrors DATA-PRO

DATA-PRO Role of the DATA-PRO

Role of the DATA-PRO Types of DATA-PRO

Types of DATA-PRO Station Type

Station Type Single-unit

Single-unit SUPER SPINDLE SS

SUPER SPINDLE SS Small-sized Explosion-proof AC Servo Motor

Small-sized Explosion-proof AC Servo Motor Amplifier Q&A

Amplifier Q&A Cable Q&A

Cable Q&A Software Q&A

Software Q&A Authentication Q&A

Authentication Q&A Motor Q&A

Motor Q&A Other Q&A

Other Q&A Explosion-Proof Type Syringe Pump

Explosion-Proof Type Syringe Pump Syringe Pump Type

Syringe Pump Type One Cup System

One Cup System Gear Pump Type

Gear Pump Type Syringe Pump Q&A

Syringe Pump Q&A PRO POWER JOINT

PRO POWER JOINT Turret Gun

Turret Gun Turret Gun 2G

Turret Gun 2G SUPER Mgnum-Powder Gun 2003

SUPER Mgnum-Powder Gun 2003 SUPER Mgnum Gun2 1998

SUPER Mgnum Gun2 1998 SUPER Mgnum Gun 1997

SUPER Mgnum Gun 1997 Coating robots

Coating robots Coating method-1

Coating method-1 Coating method-2

Coating method-2 General of coating robot

General of coating robot SWAN ROBOT

SWAN ROBOT Spray Gun

Spray Gun