Virtual coating(SWANIST)

Teaching assistant software

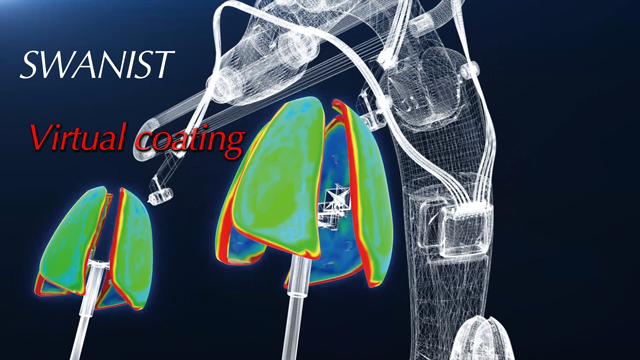

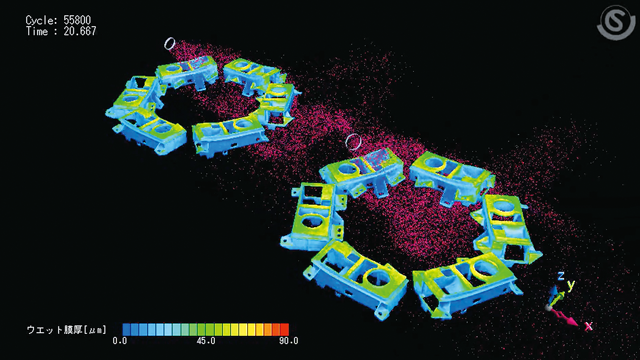

Realistic reproduction and verification of coatings in a virtual space significantly improve quality, cost, and work environment.

Offline support Teaching application

“SWANIST”, a proprietary teaching application for offline support, aims at teaching-less coating robots.

Workpiece shape data is captured, and the workpiece is properly positioned on the rotating jig. Then, the coating process is simulated in advance by generating teaching path lines (visualization), teaching simulations, virtual coating, etc., and visualizing film thickness distribution in a virtual space, leading to full production.

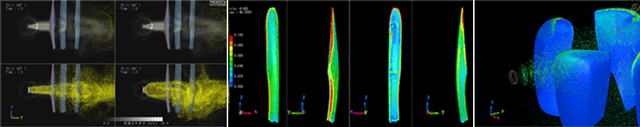

Information for more accurate coatings

Fluid analysis technology

More accurate and detailed information is needed in virtual space. Behavior of paint mist. Atomization conditions. The spraying conditions are calculated by taking into account all conditions such as air resistance, booth wind speed, etc., to simulate coating film, film thickness, etc.

Fluid analysis technology

Effects of wasted discharge pressure and patterns. The influence of the revolving speed, such as film thickness distribution, is verified.

All conditions are considered and analyzed, including the shape of the workpiece, mounting angle, and position. It also simulates the effects of a double gun on workpieces on the left and right sides.

Coating simulation by SWANIST

- Verification by fluid analysis

- Visualization of film thickness distribution

- Realization of revolving coating under optimum coating conditions

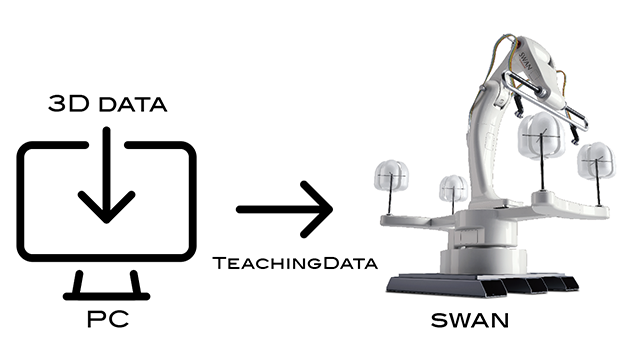

- Enables data to be converted and installed on robots

- Unify the workmanship of robots in various factories for stable production

- Reduce wasteful work costs and realize high-quality, low-cost coating production

Coating data deployment

Coating data deployment SWANIST, the ultimate offline teaching system

Coating data deployment

- Workpiece data capture

- Workpiece placement

- Teaching

- Simulation

- Coating data conversion

- Installation on robot Full production