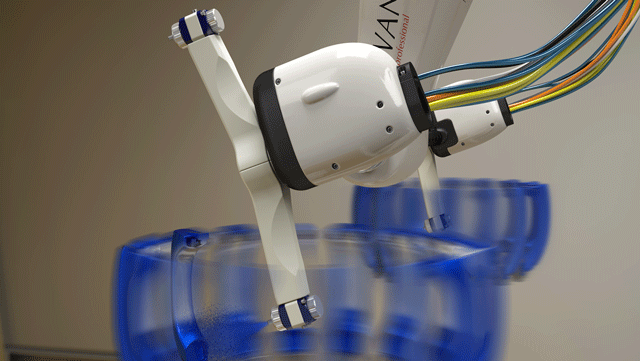

Turret Gun 2G(2 guns specification)

Available for freely combination of under, top and clear.

One robot system will be able to handle two coats

Multiple guns mounting attachment that makes one robot system compatible with two coats. It is an attachment that enables to rationalize coating production system, such as reduction of coating costs and small-sized coating equipment.

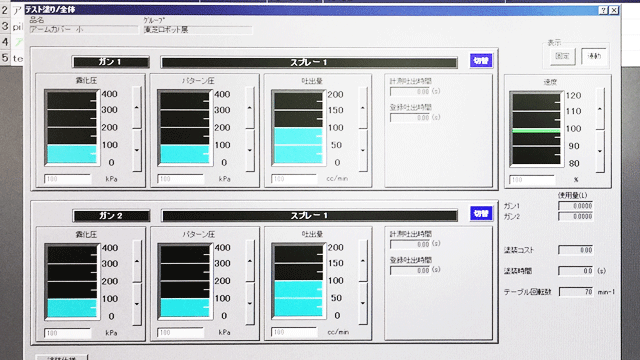

The coating conditions are also supported by the dedicated teaching assistant software "SWANIST". It is easy to set the conditions of the spray gun at the same time as teaching by input numerical values. Advanced cooperation technology between robot and spray gun can improve the coating quality and keep costs down.

Multiple guns mounting attachment developed for coating robot. Turret Gun

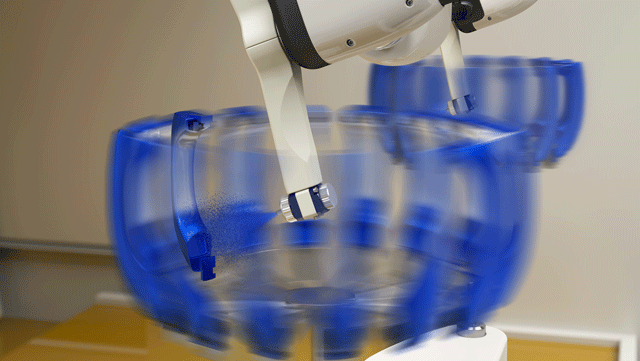

You can solve the poor coating spot problem such as coating on the back side of the workpiece.

R-Technology covers the problems for all conditions that related to the operating range of robots in revolving coating technology.

Enables to coat on the inside and outside of the workpieces placed on the circular jig with one robot. Coating conditions can also be set individually, such as inside and outside (Upper). Setting the value according to the teaching.

The inside and outside of the workpiece can be coated freely.

- It enables to coat inside of the workpiece, which is the center of the workpieces circle placed on the circular jig.

Conditions can be set together with teaching.

The inside of the workpiece can be coated - It enables coating of the lower surface of the outer circumference of the work placed on the circular jig, which is called “Upper”.

Conditions can be set together with teaching.

The inside of the workpiece can be coated

The turret gun 2G is equipped with two spray guns. By assigning one color to each spray gun, so two colors can be managed. It makes one robot become to be able to handle two coats, such as an undercoat and a topcoat.

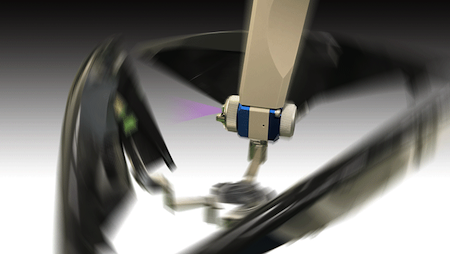

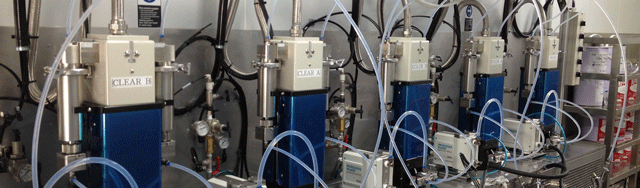

Color change system interlocking

After coating the A color, the turret gun is turned and change to the B color. It can be freely set according to the coating system, such as wet-on-wet coating or coating with a setting line. Furthermore, it will be possible to support 4-coat via a high-speed cleaning system by incorporating a special color change system.

Condition setting is easy with teaching and numerical input. It becomes Digital.

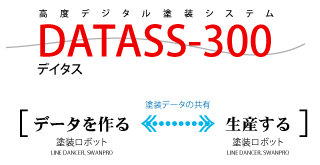

Coating conditions can be set at the same time as teaching. By setting with the teaching assistant software "SWANIST". The flexibility of the SWANIST makes it easy to input and change teaching condition settings. Furthermore, the reproducing ability of the condition settings including the saved teaching data is high, and if it is the same type robot that is made by TAKUBO Engineering, the data can be reused by simply adjusting the conditions. It maintains quality and cost with another factories.

Coating condition data included teaching data can be shared among the same robots.

Just simply re-adjust the settings like the information about position of a simple jig, all data such as teaching data, spray conditions, rotation speed, etc. can be shared.

"DATASS" is a concept about sharing the coating data devised by TAKUBO Engineering.

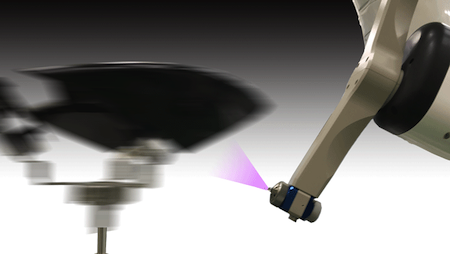

The coating equipment becomes compact

The fact of one robot can handle two coats means that the number of coating robots can be omitted, which makes it possible to reduce the size of equipment and coating costs. Moreover, the coating conditions can be digitally managed. Highly compatible and reproducible. A coating system with low cost is completed, and the risk of distributed production is also reduced.

Coating system that improves quality, cost, and environment

●In order to maximize the performance of the paint, the film thickness is adjusted and the quality is maintained without sagging, lack of hiding, or dust defects.

●It calculates and produces the appropriate amount of paint used. Reduction of air conditioning energy, space, efficiency, and total energy cost.

●Significant reduction in industrial waste and processing volume.

The turret gun supports quality, cost, and friendly for environmental issues, that is based on the idea of TOSODO.

TAKUBO Engineering supports the United Nations SDGs.

We support the SDGs.

TAKUBO Engineering supports the United Nations SDGs.

Turret Gun Coating Robot construction examples

The turret gun is suitable for coating robot systems of SWAN Pro and LINE DANCER. In addition, we can respond to production plans from 2 guns to 4 guns specification.

Type of Turret Gun

- 2 guns specification: Support 2 colors (Gun bracket 90° mounting is also possible).

- 3 guns specification: Support 3 colors

- 4 guns specification: Support 4 colors

Supported Robots

- SWAN Pro

- LINE DANCER (M Type Robot)

- ※Not compatible with SOFT BOY Pro (S Type Robot)

2 Units Pair

The turret gun is 2 units, 1 pair.