Oven DRYTEC(Oven dedicated to coating)

Using a superior heat exchanging system. Safety, quality, economy, workability, and expandability are remarkable.

Reason why it’s called Drying Technology

How to achieve the best result. Moreover, how to enable work suitable for the environment safely and efficiently. DRYTEC is designed to fit extensive workability at a high standard.

Lineup

-

DRY TEC

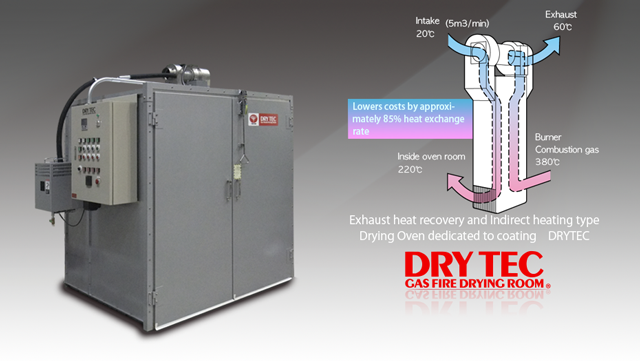

Heat-Recovery Type Hot Air Drying System

for Drying

DRY TEC is a heat-recovery type hot air drying system developed by TAKUBO that achieves superior economy, safety, and finishing.

-

Dryer GOW-1713DRY TEC

Indirect heating system Exhaust heat recovery type Hot air dryer

For coating-drying

DRYTECH Medium Dryer Suitable for drying various sizes of workpieces from small to medium and large workpieces.

This is a front and rear double-door hot-air dryer that improves productivity. -

Medium-sized GO-2018SDRY TEC

Indirect heating method Exhaust heat recovery type Hot air-drying oven

for Drying/For coating-drying

DRY TEC Middle-sized drying oven Supports drying of workpieces of various sizes such as small to medium and large workpieces.

-

Custom-made oven GOW-2019SDRY TEC

Indirect heating method Exhaust heat recovery type Hot air-drying oven

for Drying/For coating-drying

DRY TEC Medium type drying oven Supports drying of workpieces in various sizes such as small to medium and large workpieces.

A front and rear door type hot air-drying machine that improves productivity. -

Dryer GOW-2522DRY TEC

Indirect heating system Exhaust heat recovery type Hot air dryer

For coating-drying

DRYTECH Medium Dryer Suitable for drying various sizes of workpieces from small to medium and large workpieces. This is a front and rear double-door hot-air dryer that improves productivity.

-

GOW-253040DRY TEC

xample of installation of Passing-type drying machine, DRY TEC Special order GOW-253040

for Baking/For coating-drying

Example of installation of Line-type drying machine, DRY TEC Special order It can be incorporated into manual and automatic trolley lines.

-

Large-size oven, GO-322726SDRY TEC

Special order, Large-size drying machine with one-side door

For coating-drying/For large workpieces

Example of installation of Large-size drying machine, DRYTEC Special order Drying machine with one-side door suitable for big-size work component to coat

-

Large-size oven, GO-4225DRY TEC

Special order, Large-size drying machine

For coating-drying/For large workpieces

Example of installation for Special order of DRYTEC, Large-size drying machine Drying machine with one-side door suitable for big-size components to coat

-

Custom-made DRY TECDrying Oven, Drying Device exclusively for Coating

Special Order Product, Large-sized Drying Device, GO-503050

for Drying/Water-based coating material/Solvent-based coating material/For coating-drying/For large workpieces

Custom-made DRY TEC, Best Seller of Drying Oven, Drying Device exclusively for Coating, Large-sized Drying Device exclusively for Coating for example This is an example of Custom-made DRY TEC. DRY TEC is also available for Camel-back Drying Oven (Trolley specifications), Annealing, Far Infrared Ray specifications, Automatic Conveyor specifications and other types.

-

DRY TEC Q&ADedicated coating drying machine

Q & A

Questions and answers about DRY TEC, the dedciated drying machine for coating are described.

Best Seller Machine for Coat Drying, DRYTEC

More than 45 years since sales started in 1975, we have kept one belief.

It is that our oven is dedicated to coating. DRYTECH is an unparalleled oven dedicated to coating, and all functions are adjusted to coating.

We show you typical features and benefits.

Secures safety for drying coated items

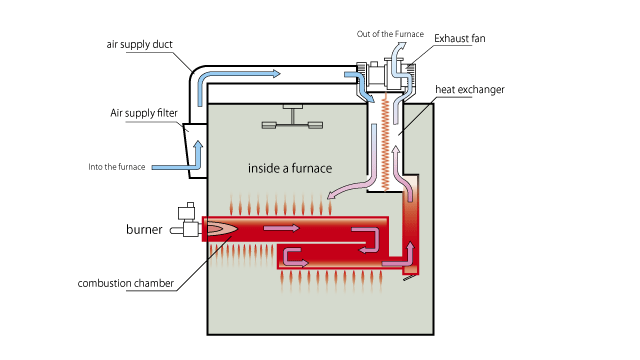

- Secures safety by designating to separate the combustion chamber from the furnace inside. The structure doesn’t allow sparks to enter inside the furnace filled with solvent.

- Uses the indirect heating system for efficient drying.

Equips with comprehensive performance including safety, economy, quality, workability, and expandability.

- DRYTECH can supply the heat energy and sufficient oxygen needed for drying. Intaking 5m3 of fresh air per minute with sufficient combustion volume enables an environment where paint can perform well.

- Uses a panel structure sandwiching heat insulator, it is easy to install, relocate, and expand, and can accommodate batch type, line type, and even mountain-shaped drying ovens.

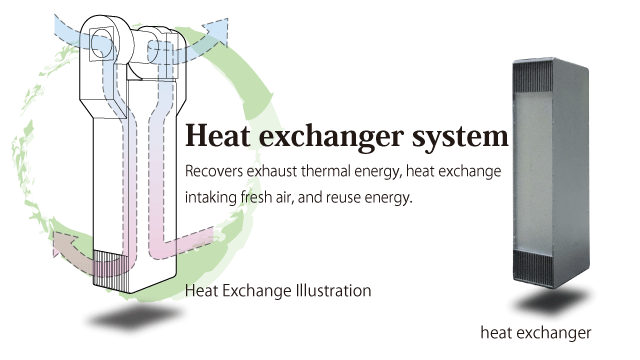

- Heat exchanger, which TAKUBO Engineering is proud of, is the heart part of DRYTECH. The heat exchange ratio of approximately 85% contributes to lower energy costs and reduces coating costs.

Safety required for oven

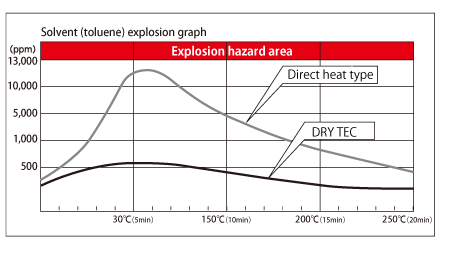

Safety in coating-drying means that evaporated solvent does not ignite because no spark enters.

Do not put any sparks from burners or other sources of heating time into the furnace.

Heat the furnace safety, and cure the paint.

Do not allow sparks to enter the furnace.

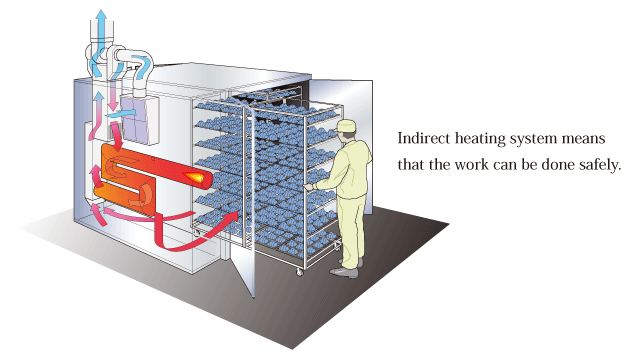

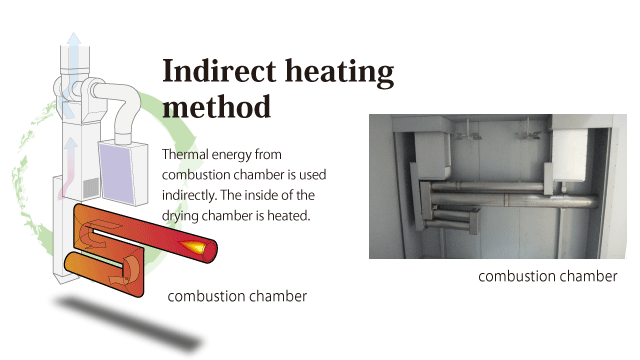

One of the drying systems Indirect heating system

- There are 3 kinds of coating-drying systems, “Hot air drying”, “Near infrared drying”, and “Far infrared drying”. DYTECH uses “Hot air drying system”. This system is further divided into direct heating and indirect heating systems, and DRYTECH uses the safer indirect heating.

- DRYTECH uses a hot air-drying system of indirect heating type and separates the combustion chamber and drying chamber.

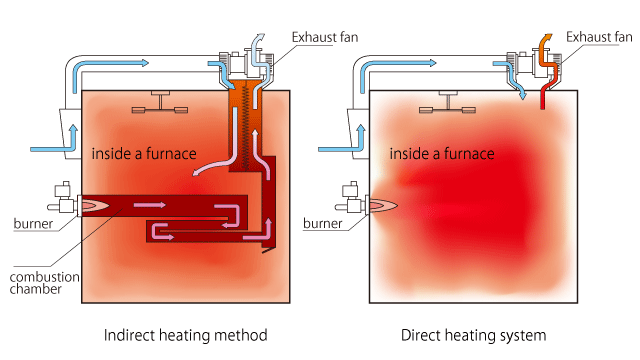

DRYTEC improves safety by using an indirect heating system. Prevents evaporative gases from affecting the coated film, during the process of heat applied to the paint and solvents evaporate. Compared with the direct heating system, the indirect system does not allow sparks to enter the furnace. Avoiding the risk of ignition, DRYTEC is an extremely safe oven.

Do not put sparks in a furnace filled with solvent.

- Combustion energy transfers heat energy at the heat exchanger through the combustion chamber and is discharged outside the furnace.

- This combustion type is extremely safe compared with the direct heating type.

Preventing Gas Checking

- Prevent the negative effect on the coating film by intaking 5 m3 of fresh air into the furnace every minute and draining evaporated solvent in the furnace.

- Abundant oxygen and uniform thermal energy form a defect-free coating film.

Pre-purge and post-purge functions improve safety, quality, and performance

- Pre-purge ventilates the furnace. A lot of water is produced, especially when gas combustion starts. Prevents whitening (brushing) and other effects on the coating film by venting the water.

- Post-purge improves furnace safety by cooling and purifying the furnace after drying.

2 foundation designs. Indirect heating system and Heat exchanging system.

Pursuing the process of coating hardening, rational mechanisms are inevitably found.

Indirect heating and heat exchange systems.

All created benefits including higher quality, lower cost, and workability are drying technology.

Heat exchanger system

- Supply air and exhaust air. We use a uniquely developed heat exchanger in this process. Reuse heat energy by transferring about 85% of exhausted heat to supplied air. Reduce energy costs related to drying.

- Exhausts 5m3 per minute outside the furnace. The heat exchange system can rationally replace the oxygen needed for coating film formation with evaporating solvents that have a negative effect.

Indirect heating system prioritizes safety.

- The inside of the furnace is an explosion hazardous area for solvents. DRYTEC uses an indirect heating system. The structure ensures safety and security by not allowing any spark inside the furnace, which is filled with solvent.

- Indirect heating system provides the furnace with good temperature distribution and almost uniform heating. Prevents variation in drying quality and improves drying efficiency. In addition, even when the furnace is almost completely filled with workpieces, uneven drying is unlikely to occur. (※Circumstances may vary with the shape of the workpiece and the performance of the paint)

Safety mechanism Indirect heating system

Paint dries (cures) when heated. Solvents in the paint evaporate during the heating process and produce a highly flammable situation. DRYTEC uses an indirect heating system with a separate combustion chamber to prevent ignition in the drying chamber.

Drying room is always in a safe area.

Evaporated solvents in the drying room are extremely flammable and can be very dangerous if the concentration is exceeded. DRYTEC keeps the inside of the drying chamber in a safe area at all times by taking in 5m3 (10m3 or more for GO, GOW25 and above models) of fresh air per minute.

Difference between Indirect heating system and Direct heating system

- Indirect heating system (hot-air type) DRYTECH: Do not heat the furnace directly. Heat the furnace indirectly by separating the combustion chamber.

- Direct heating system (direct heating type): Heat the furnace directly to dry the coated material.

Dry-tech with outstanding coating quality

- Since no combustion gases enter the furnace, gas checking does not occur. There are no drying problems caused by the dryer.

- DRYTEC can adapt to water-soluble paints too.

Be suitable for many heat-sources

- DRYTECH can be suitable for a variety of heat sources including town gas, LPG, electricity, and far-infrared radiation.

- Depending on materials and paint, accommodate widely baking furnaces, electric furnaces, solvent-drying furnaces, drain drying, and UV furnaces.