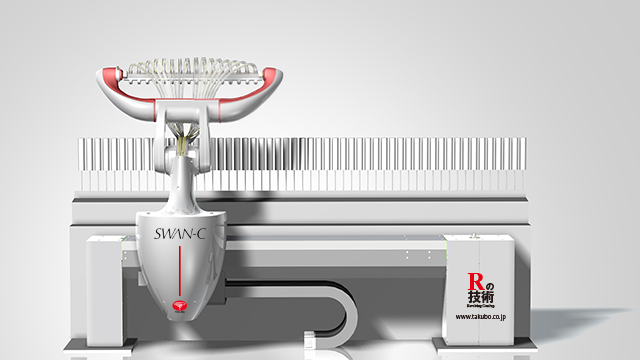

SWAN-C(coating robot for spindle type coating line)

Coating robot born from ideas and innovation

To spindle line

SWAN-C is born, coating robot for spindle type coating line. For significant reduction in coating costs

General spindle coating has the advantages of low installation cost equipment and flexibility in workpiece shape and size. However, it is a coating method that wastes a lot of paint and it is very difficult to reproduce the coating conditions.A considerable amount of work time and paint are spent on setting conditions and test coating each time the object to be coated changes. It is a heavy work load to finish while adjusting.In addition, due to the decrease in the number of engineers, it can be said that it is too difficult to "reduce the amount of paint used" and "pursue coating". In recent years, especially in the cosmetics industry, the types of products and the expressiveness required have increased, and there is a limit to the current spindle coating method, making it difficult to pursue coating costs and quality. With the aim of solving these difficult problems, the swan robot "Swan-C" that can be installed on the existing spindle painting line has been developed.

For spindle coating line, coating robot, SWAN-C

New coating robot system, SWAN-C

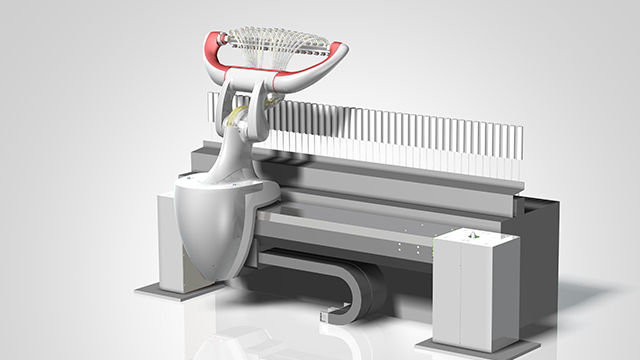

Since the original compact pressure-resistant AC servo motor is used, it can be used in the explosion-proof area. Can be installed on the existing spindle line. Teaching assistant software “SWANIST” standard equipment, easy teaching and digital management makes it possible to significantly reduce coating costs compared to conventional fixed gun type spindle coating.

・Target spindle equipment: Spindle conveyor speed: 3 to 5 m / min (when the pitch is 50.8, the number of production is 3,600 in a 15 sec cycle / h)

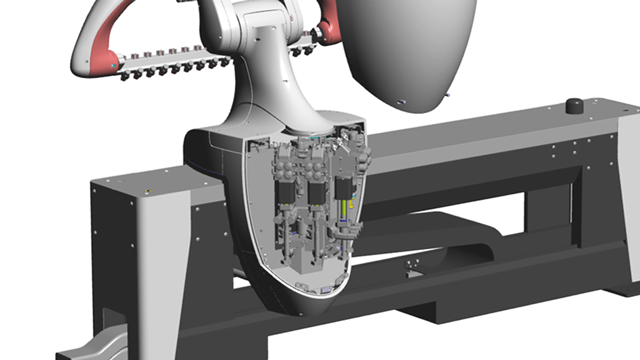

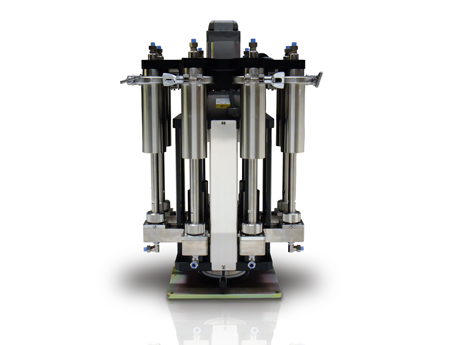

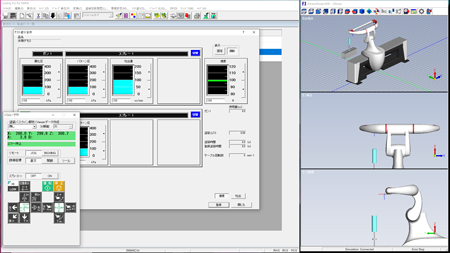

Small syringe pump integrated type

Built-in small syringe pump for paint supply in the robot body. The syringe pump system has also been newly developed exclusively for Swan C. The standard specification of the syringe is 10cc. Connect 16 cylinders for 16 guns. One-to-one design of syringe pump 1 for the original gun 1. Achieves stable coating by eliminating atomization and paint variation.

New development of small syringe pump system exclusively for Swan C

The syringe pump controls the paint in 1CC units. It enables precise control of paint supply and calculates the amount of paint used to reduce wasteful paint use.

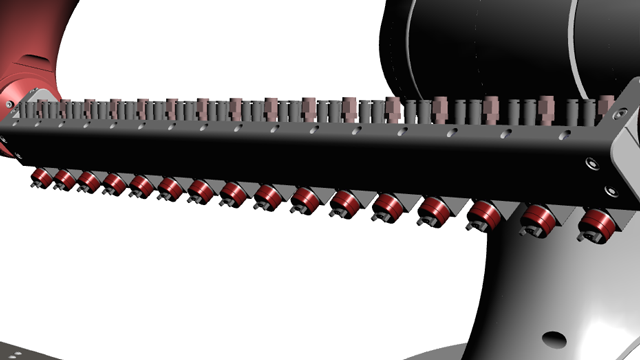

Highly finely divided ultra-compact dedicated original gun development, 16 standard equipment

Developed the ultra-compact automatic gun Sukotti gun series, exclusively for Swan-C. Excellent in atomization at low pressure, and succeeded in reducing size and weight. Equipped with 16 guns as standard, it can be controlled for each gun. Conditions can be set and ON / OFF can be set according to the work pitch.

- Newly developed small Sukotti gun R19T exclusively for SWAN-C

- Achieves high-quality coating with excellent atomization at low pressure

- Optimized for multiple-layer and thin-film rotation coating R-technology

- Developed a small syringe pump exclusively for SWAN-C

- One-to-one connection between syringe pump and Sukotti gun

- On / off control of each gun is possible

Newly developed automatic gun exclusively for Swan-C, Sukotti gun R19T

・Ultra-compact high-performance original gun with a discharge rate of 20 to 50cc, an air usage rate of 40ℓ / min, and a main body of 40g.

・Excellent in atomization at low pressure and realizes high quality coating film.

A wide range of compatible works

We support work from lipstick caps, toners, mascara, eyebrows, atomizers, fountain pens, ballpoint pens, and other cylindrical parts, as well as water bottles, lenses, bottles, bowls, plates, portable mobile parts, and automobile parts.

Compatible works

- Bowls

- Plates

- Water bottles

- Bottles

- Lenses bodies

- Cosmetic bottles

- Mascara

- Eye shadow

- Eyebrows

- Automotive parts

- Mobile communication parts

- Printer shafts

- Others

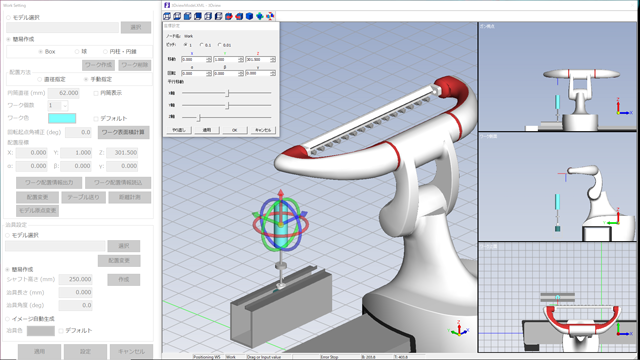

Teaching assistant software

Teaching assistant software "SWANIST" standard equipment. Teaching is easily assisted, and condition settings can be handled in detail, making saving and playback easy. The accuracy of reproducibility is also high, and teaching data, condition setting data, etc. can be digitally managed.

Teaching assistant software "SWANIST"

・In 3D virtual space, it is possible to intuitively operate the angle, position, number, etc. of the work.

・You can share work placement information and transfer placement data for jig manufacturing to a jig supplier.

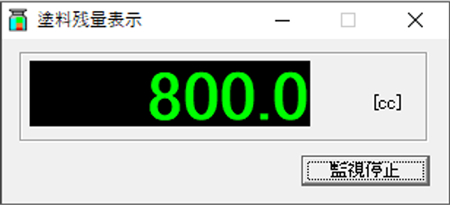

Paint remaining amount display

・It monitors the remaining amount of paint and displays the remaining amount as a warning function and the amount of paint charged.

Benefits of introducing Swan-C

Cost reduction

Shortening the time for setting conditions

Significant reduction in time for setting conditions by digitizing coating conditions

Reduction of working time

Significant reduction in color change time and setup change time

Significant reduction in solvent consumption

Significantly reduce cleaning thinner consumption, industrial waste treatment, and VOC emissions.

Realization of high quality coating

Equipped with "SWANIST" software specializing in revolving coating as standard equipment

Standard equipment of micro discharge syringe pump and small dedicated gun

High quality coating is possible by digitizing coating conditions

Correspondence to complicated shapes

Correspondence to production types

Can be incorporated into existing spindle coating line equipment

Adaptation to various lines

Arm configuration that can expand the number of mounting gun (option: up to 24 guns)

Support for small-lot, high-mix production

Main specifications of SWAN-C

Specifications

| Loadable capacity | 5 kg | |

|---|---|---|

| Moving range | Maximum work diameter150mm、H200mm | |

| Motion axes number | 3 robot axes + 1 X axis | |

| Gun number | 16 spray guns as standard specifications | (pitch as 50.8mm) |

| Capacity of syringe | 10cc as standard specifications | (16-cylinder syringe pump) |

| Conveyor | Conveyor, 3〜5 m/min spindle conveyor speed | (production volume is 3600pieces/hour with 15second-cycle with 50.8mm pitch) |

Features of R19T, small-size spray gun exclusively for SWAN-C

| Coating material discharge volume | 20cc〜50cc | (paint discharging volume) |

|---|---|---|

| Air use volume | 40ℓ/min | |

| Weight | 40 g |

Please contact us for coating trial.Link to product page

We look forward to having a request for coating test and demonstration by SWN-C at our laboratory in TOGANE Technical Center.