What is SWAN Robot?(Coating Robot)

SWAN, the coating robot system to master coating

Various kinds of technologies necessary for coating are integrated. As a center of our original coating technology, R-technology, the essential requirement to increase coating precision, which we got in our development for mobile phone coating, is inherited and also completed in SWAN. 3D Simulation system of the new Teaching Assist, which is beyond the frame of usual robot teaching, will be newly installed on SWAN so that the automation can continue to evolve furthermore.

Features

Super small size “Explosion-proof Motor” is used to increase safety.

Super small size explosion-proof motor for SWAN is developed originally. From the viewpoints of small-size and safety, TAKUBO has been developing even drive components. This motor is adopted not only for SWAN but also Syringe Pump and Handling Robot in order to increase their accuracy and safety performance.

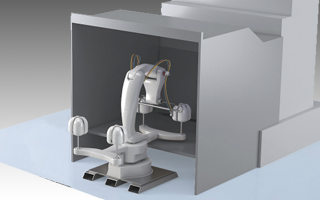

Compact design “SWAN” is easy to install.

SWAN robot has the fame to use a hand-lifter so that it is easy to set the robot in front of the existing booth. It is flexibly possible to make replacement, renewal and expansion of the existing robot. Because guns, One-cup system of paint supply equipment and others are integrated, it is possible to start up the production very soon. Combining with Oil Booth as option, a safe and quiet coating production device can be easily realized.

Quality and Cost depend on “Revolving Jig”.

TAKUBO is supporting the customers regarding Jig Design so that they could eliminate waste movement of the robot or sagging/lack of hiding coating, and also could realize low-cost coating production with the minimum paint consumption. We are providing such knowledge and know-how at our technical demonstration room just after conclusion of the agreement about the system.

High precision “W-turn” not to make any defects.

“W-turn”, our original developed handling device for coating, is installed as standard equipment. It has a precise turning mechanism and high position accuracy. This high-grade handling device can manage both manual and automatic operation for SWAN with a large variation.

“R-technology”to correspond to every work

From tall workpiece to wide one, any kinds of workpieces are acceptable on condition that it fits within rotation diameter 500 mm and height 500 mm (there could be some unacceptable ones depending on paint or shape or location to coat).

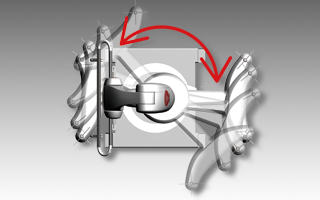

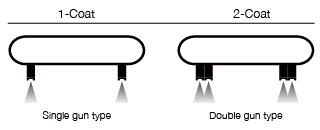

“Cross motion bar” to manage 1-coat and 2-coat only by one robot

- “Cross motion bar”, the new developed gun support bar for multiple guns with very unique (front and back, left and right) movement, can simultaneously coat 2 ring-jigs. It can manage both 1-coat (with single gun type) and 2-coat (with double gun type).

“Cross motion bar” to manage 1-coat and 2-coat only by one robot - High-grade color change is quickly made with few paint consumption by the color change system. Coating cost can be reduced very much.

Maximum efficiency with a minimum of mechanism, the new developed “Cross motion bar”

“Cross motion bar” exclusively for the new developed robot of SWAN is a special support bar with up and down, left and right movement. Its original motion technology has realized the revolving coating. The robot motion suitable for the revolving coating can provide high quality and low cost.

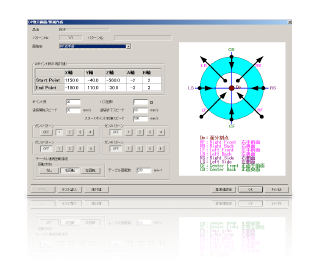

Original teaching software to reduce the coating time

- Using our original developed software, “DISK PACK” and some other software, you can easily make teaching work or condition setting without any use of robot languages. They are our original teaching software to reduce the coating time.

Original teaching software to reduce the coating time - Teaching pendant is used as supporting tool for positioning of the robot. Regarding input of conditions, you can use the software in the build-in PC.

“One-cup system” to control the paint and to eliminate waste of the paint

- The paint supply device “One-cup system” is installed as standard equipment. As supply mechanism, the explosion-proof syringe pump is installed to control the paint precisely in 1 cc unit. High-grade control technology can reduce waste consumption of the paint.

“One-cup system” to control the paint and to eliminate waste of the paint - “One-cup system” with cup refill type is used for paint supply. Refilling only the required paint amount can dramatically reduce waste of the paint consumption. And moreover the special Teflon coating in the inside of the cup can reduce waste of the cleaning solvent consumption because of high wash ability.

“Robot technical training” for your firm understanding and our firm support

- For your safe and functional use, we are pleased to give a technical training or teaching instruction. Also we would like to make a back-up support of “Coating”. If you want more reduction the coating time, revision of the teaching data or development of more appropriate revolving jigs, we would like to provide our best support.

“Robot technical training” for your firm understanding and our firm support - We are accepting a coating test or demonstration at the demonstration room in our TOGANE Technical Center from time to time (reservation is required).

Coating test accepted at any time (reservation is required)

- Coating test is acceptable at the demonstration room in our TOGANE Technical Center. SWAN robot or other coating robots can make demonstration or coating test at the real coating room (clean room with temperature control) at any time (reservation is required). Please contact the inquiry corner in our web site.

Coating test accepted at any time (reservation is required) - Paint and workpiece for coating demonstration should be provided by the customer. In case of the paints specified for dangerous goods, we cannot accept such paints. Please ask us before sending.After the demonstration, the remained paint and the workpieces are returned to the customer.

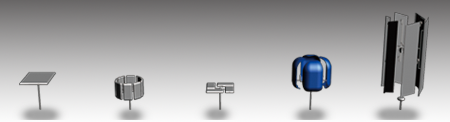

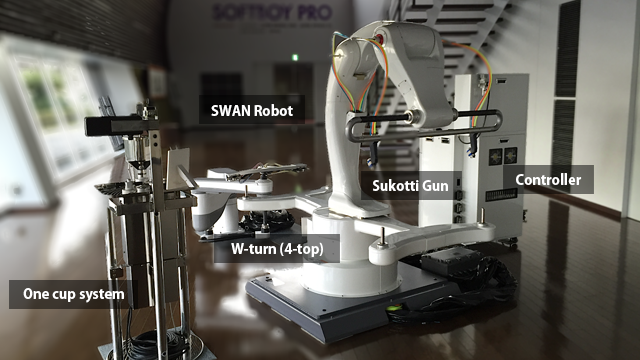

Standard equipment for SWAN robot, example of 1600-4T

Standard equipment

SWAN Robot body

Cross Motion Bar, 4-top high precision handling equipment with rotation mechanism

One cup system Interlocking type with SWAN Robot, Paint supply system

High accuracy fixed quantity supply equipment (100cc x2), Syringe Pump

Dedicated controller for SWAN Robot

PC with controller and monitor for SWAN Robot

Low-pressure and High-atomization automatic gun, Sukotti Gun (for 1 coat)

1 coat (with 2 guns) Standard equipment

High-pressure cleaning system, Quick Cleaner

High-speed paint hose cleaning system, to clean the remained paint in the hose at high speed by high-pressure air

Optional items

Additional Sukotti Gun

Up to 2 coatings, maximum 4 guns are possible to load. ※To be revised to Syringe Pump for 4-gun type.

SWAN Robot Official Brand SiteLink to product page

This is an official brand site for SWAN Robot. You can see a lot of details about the technical information, specifications, size, and suitable work components etc. about SWAN Robot(※Separate from TAKUBO corporation site)http://www.swanrobot.jp/e/

Coating test accepted at any time (reservation is required)Link to product page

Coating test is acceptable at the demonstration room in our TOGANE Technical Center. SWAN robot or other coating robots can make demonstration or coating test at the real coating room (clean room with temperature control) at any time (reservation is required). Please contact the inquiry corner in our web site.