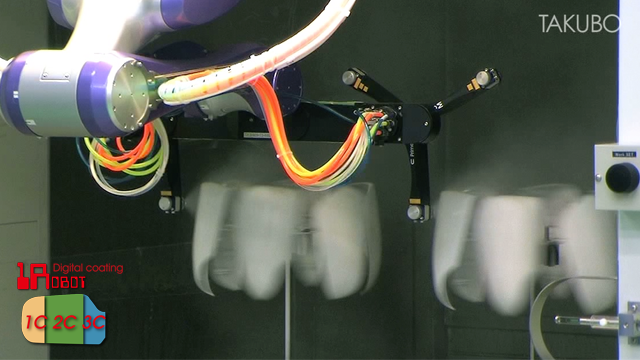

3 coatings produced by only 1 robot(Outside mirror coating system)

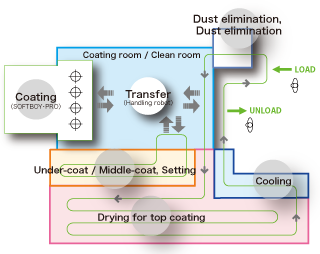

Separating a coating robot from the conveyor line and using a handling robot for automatic transferring will make it possible that one coating robot can produce up to 3 coatings by itself. 6 spray guns are mounted on a robot arm. After flushing, the next coating is executed with quick color change. Outside mirror coating equipment has become very compact.

3 coatings are realized by only 1 robot.

1R3C/One-Robot Three-Coat

1R3C/One-Robot Three-Coat One robot holds 6 guns and controls them. So 2-coating and 3-coating productions by only one line becomes possible. Because of SOFTBOY PRO of the ceiling-suspended robot, this kind of production (technology) can be realized. Using the technology and know-how, we have developed a dedicated coating system for outside mirrors so that any kind of waste issues in general systems can be eliminated. Because only one booth can manage 3 coatings, the equipment becomes very compact so that the energy cost for air-conditioning is drastically reduced. Furthermore, the revolving coating technology, “R-technology”, and the system technology realize substantial reduction of the paint consumption volume. ※1 1 Regarding very challenging and changeable production such as outside mirror coating with multi-kind and small-quantity production, this system can manage it in low-cost, high-efficiency and high-quality.

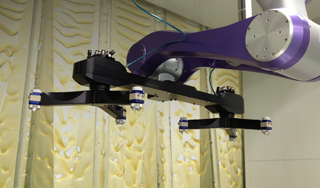

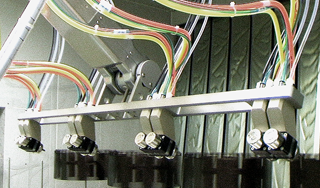

Multiple-gun unit

Turret gun-3

Arm extending over three radiation with 3 guns can make coating even the inside of the work components according to the outside mirror shapes. Standard unit for outside mirror (revolving) coating.(2017年現在) ・Possible to make maximum 3 coatings ・Possible to coat the inside of the workpiece

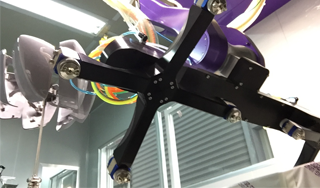

Turret gun-4 (Cross gun unit)

Multiple-gun unit mounting 4 guns with another name “Cross gun”. Possible to coat maximum 4 coatings. ・Possible to make maximum 4 coatings ・Possible to coat the inside of the workpiece

PRO Power Joint

Gun Attachment to mount multiple sets of 2 spray guns at a constant pitch on the horizontal row.。 ・Possible to make maximum 2 coatings ・Collaboration with Color-change system

What is 1R3C (One-R Three-C)?

“1R3C” is a short name of the coating system for outside mirror parts, in which one robot system can manage 3-coating production. By the way, “1R2C” means the system in which one robot system can manage 2-coating production. And “1R4C” means the system in which one robot system can manage up to 4-coating production. This “1R3C” coating system is suitable not only for outside mirror parts but also other parts. Moreover it is possible to design other multiple coating production such as Wet-on or Bake-on by using this system.

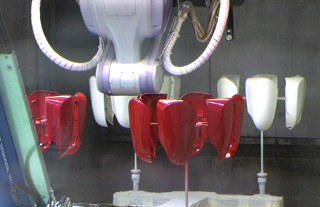

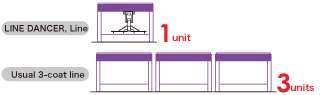

“LINE DANCER”, the dedicated coating system for outside mirror

3-coating production by only 1 robot

Separating a coating robot from the conveyor line and using a handling robot for automatic transferring will make it possible that one coating robot can produce up to 3 coatings by itself. After flushing, the next coating is executed with quick color change. Coating equipment has become very compact so that the coating environment is improved dramatically.

Substantial reduction of air-conditioning energy cost

Because 1 coating needs 1 booth in general production, the system with 3 booths is designed in case of 3-coating production. The air-conditioning energy cost increases according to the number of booths so that it brings a significant impact on the cost. In this outside mirror coating system, the required air-conditioning energy cost is that for only one booth because 3-coating production can be managed by only one booth. Air conditioning energy for two booths will be reduced compared to the case of 3-booth production.

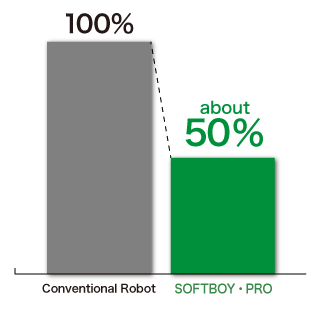

Possible to reduce 50% of the paint consumption volume

Our coating technology cultivated in development of mobile phone coating is utilized in outside mirror coating. We have succeeded about 50% reduction of paint consumption volume by combining “R-technology” with multi-layer/thin-film coating, “Syringe Pump of the paint quantitative supply device” which TAKUBO introduced first in the industry as paint supply device, the control system and other latest peripheral technologies. ※The paint consumption figures in the graph are our in-house coating test data.

Coating data sharing

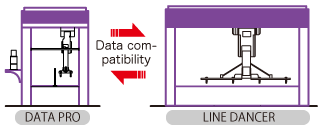

Coating test or Coloring work are conventionally executed at a production line. This work (sometimes it takes long time) brings waste of energy, reduction of productivity (due to stop of the production line) and also heavy burden on the workers. “DATA PRO”, the dedicated coating data generation robot, make it possible to separate production work and coloring work or coating test. Because of the high-grade data compatibility, it is able to realize the high efficiency of the work including coating condition settings and to solve the color error problems which occur among the factories located at different places so that

New revolving coating technology, “R-Technology”

R-Technology is the revolving coating technology by robot. The coating technology of “SOFTBOY PRO LINE DANCER” is to mount multiple number of outside mirrors on a circle jig, to turn 4 jigs at the same time CW and CCW, and to coat the workpieces on the jigs by the multiple guns of the robot. Controllability of condition setting is much better than those of reciprocator or independence type (balance-arm) robot so that subtle film thickness control is possible to produce.

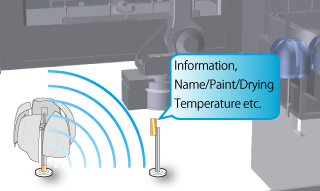

New production management system by ID tag in the future

ID tag is installed on a work jig. In the near future, the ID tag holds various information such as paint, drying conditions and so on, and the sensors read such information and spread the orders to each monitor. Human error can be avoided as much as possible in the production process with a lot of model change. We are aiming a perfect automation production system.

Renewal date: July 21, 2017