SWAN-application

SWAN is very useful in every kind of coating system from manual to automatic one.

SWAN is an independence-type explosion-proof dedicated coating robot with 4 axes. It is possible to start coating production just by setting in front of the existing booth because all of the necessary parts and machines such as Sukotti Gun, originally developed dedicated gun, W-Turn, transfer device, One-cup Syringe Paint Supply System, Controller and so on, are already equipped. In addition, setting of CoSWAN, our original developed explosion-proof handling device, will make it possible to have various kinds of production such as multi-color or mass-production automatic systems.

Application range of SWAN is very wide.

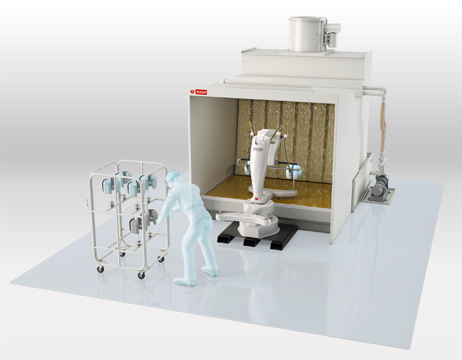

Manual system, standard system example in which operator works

Standard system

Operator works to transfer work pieces from cart.

It is the most typical use example. For introduction of coating robot, replacement of existing robot and so on.

Batch-type Coating

- Newly introducing coating robot

- Multi-kind and small-volume production

- Replacement or renewal of robot

- Introduction of Revolving Coating Technology

- Reduction of coating cost

Automation system, automatic coating system example

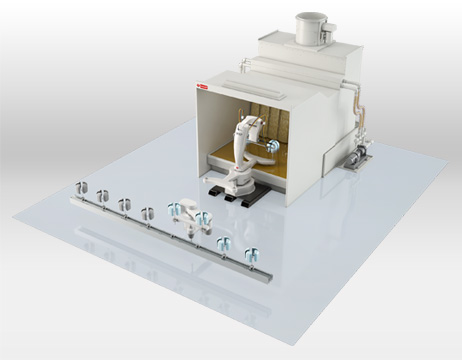

1R1C

CoSWAN, transfer device for coating, is combined to 1 set of SWAN robot to make an automatic 1-coat operation continuously.

Combining CoSWAN will keep conveyor line clean by preventing it from over-spray so that high-quality coating performance is maintained. It is also possible to set in clean room system.

Example of 1-robot and 1-coat automatic coating system

- Automatic production of 1-coat

- Automation of coating

- Multi-kind and small-volume production

- Possible to set in clean room

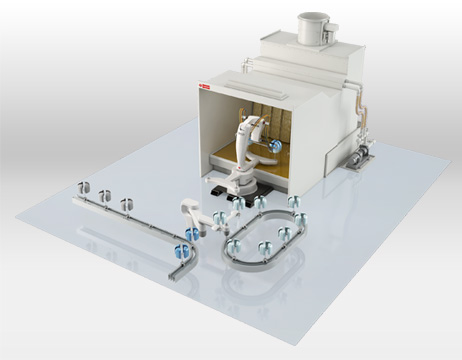

1R2C

Automatic production of 2-coat is made by 1 robot.

CoSWAN, transfer device for coating, is combined to 1 set of SWAN robot to make 2-coat operation possible by adding a setting zone in a very compact line (expecting outside mirror as work piece to coat).

Reduction of cleaning solvent consumption in color change, reduction of operation time and difficulty can be realized.

Example of 1-robot and 2-coat automatic coating system

- Automatic production of 2-coat by 1 set of SWAN robot

- Reducing consumption volume of paint and solvent in color change substantially

- Reduction of both time and difficulty in color change

- Possible to use in clean room

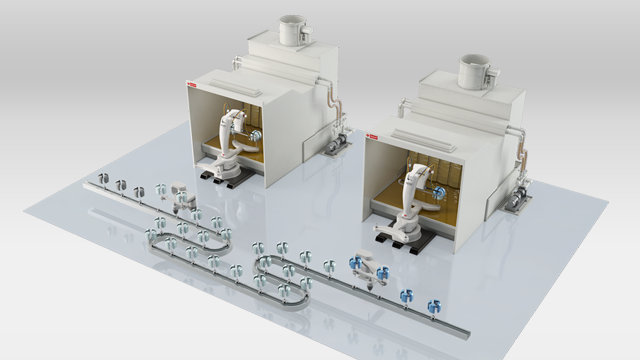

2R2C

Example of 2-coat automatic coating by 2 sets of SWAN robot

2 sets of CoSWAN, Explosion-proof Transfer Device for Coating, are set to transfer work pieces to conveyor line.

It is able to manage any kind of volume production including small lot, middle lot and mass production. It is also suitable for multi-kind production with many color changes.

Example of 2-robot and 2-coat automatic coating system

- Useful for existing conveyor line just by setting SWAN robot and CoSWAN

- Possible to set in clean room

- Reduction of paint consumption volume

- Substantial reduction of operation time and difficulty in color and program changes

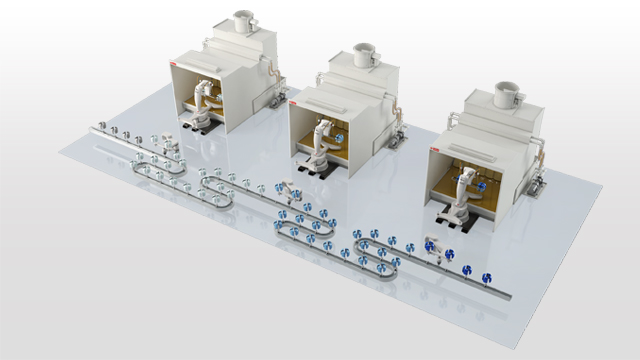

3R3C

3 sets of SWAN and 3 sets of CoSWAN, Explosion-proof Transfer Device for Coating, are set in front of conveyor line.

Each SWAN robot is in charge of 1 coat so that 3-coat by 3-robot is continuously produced.

Example of 3-robot and 3-coat automatic coating system

- 3-coat production is realized by compact system.

- Substantial reduction of paint consumption volume

- Substantial reduction of consumption volume of cleaning solvent and waste solvent in color change

- Suitable for multi-kind and small-volume production

- Suitable for small-lot production to mass-production

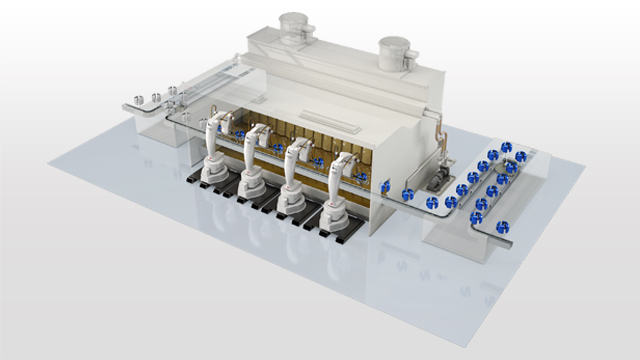

4R1C DragonLine

4 sets of SWAN S-type are set to make 1-coat production by coating 8 rings on the revolving jigs simultaneously. SWAN S-type robots are set in a row, and the accumulation mechanism devices are also installed at the both sides of the booth (at the front and back of conveyor line). Mass-production can be realized by combination of SWAN and DRAGON LINE. Also in this case, required booth is only one so that the energy cost for air supply and exhaust can be reduced.

4R1C, Coating system for mass-production by 4 SWAN S-type robots and DRAGON LINE

- Compact system for mass-production

- Energy Cost Reduction by DRAGON LINE

- Substantial reduction of coating cost by realizing Revolving Coating

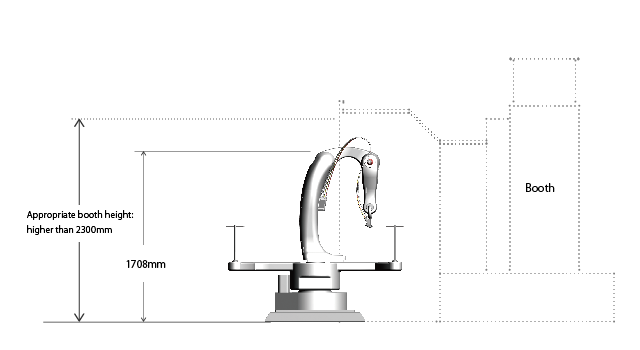

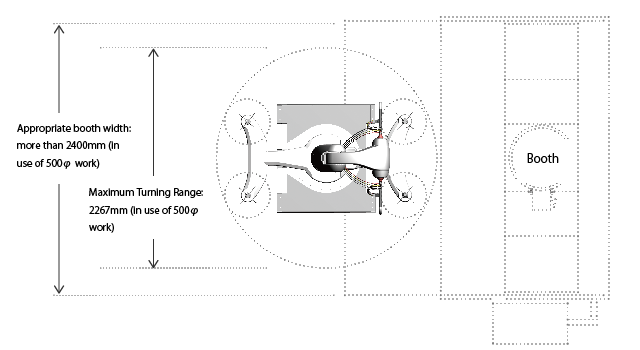

Appropriate Booth Size for SWAN robot

Booth Height is higher than 2300mm, Booth Width is more than 2400mm (in use of 500φ work) as standard size

Reference setting side-view about effective booth height

Reference setting top-view about effective booth width

“CoSWAN”, newly developed Explosion-proof Transfer Device for Coating

CoSWAN, Explosion-proof Transfer Device for Coating, can be used in a fire risk area by introducing our original developed small-size explosion-proof motor.

This CG is a conceptual picture made in a designing stage. It might be different from actual machine.

Release date: October 27, 2015

SWAN is a registered trade-mark of TAKUBO ENGINEERING CO., LTD.