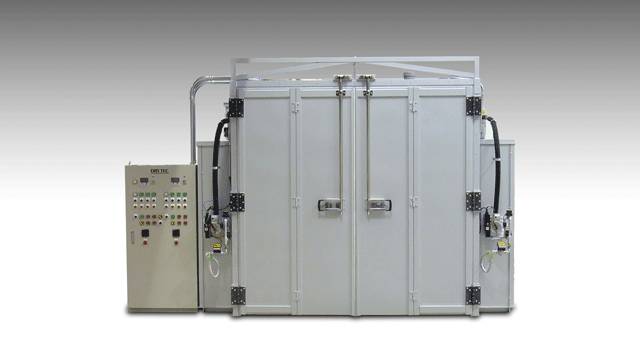

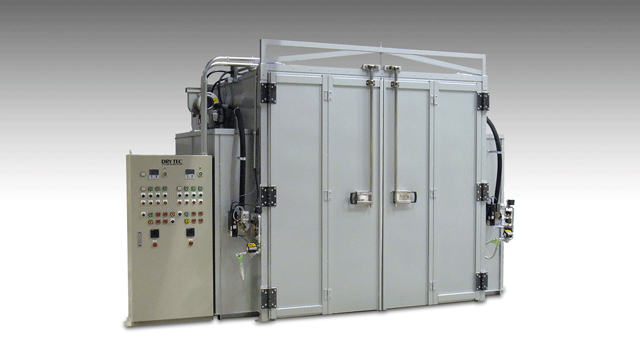

Dryer GOW-2522(DRY TEC)

Indirect heating system Exhaust heat recovery type Hot air dryer

DRYTECH Front and rear double-door Medium Dryer Batch production is supported

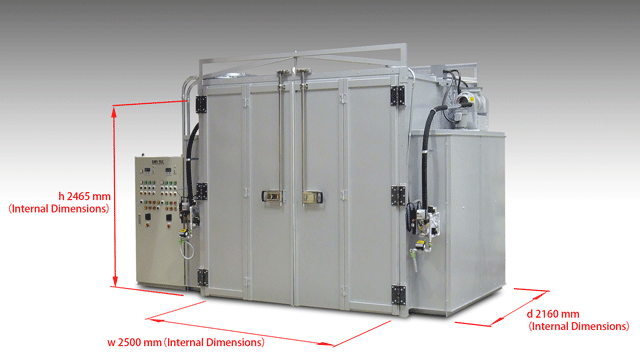

Dedicated coating dryer Front and rear double-door DRYTECH Drying furnace for batch production.

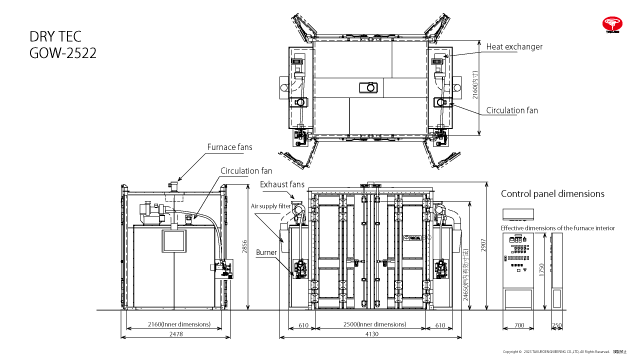

Size (effective size of furnace interior): w 2,500 mm x d 2,160 mm x h 2,465 mm, double-door type.

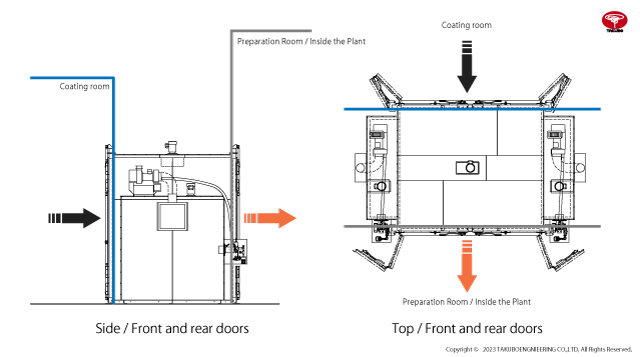

The entrance and exit can be used separately, such as in the coating room and the preparation room, or in the finished room. Drying is done from the clean room (coating), and the baked products are taken out from the preparation room, thus enhancing work efficiency.

This dryer is specially designed for coating and can be used for various sizes of workpieces, from small to medium and large sizes.

*There is no ceiling panel reinforcement as of March 2023.

DRYTECH GOW-2522

*There is no ceiling panel reinforcement as of March 2023.

※There is no ceiling panel reinforcement as of March 2023.

Front and rear door type

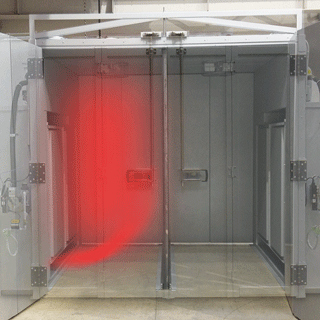

DRYTECH What is a front and rear door?

- These are doors that separate the entrance and exit of the drying oven and make them available for use.

The coated workpiece is placed in the furnace, and it is taken out by the rear door side after drying. - It improves work efficiency.

- Prevents coating and drying defects.

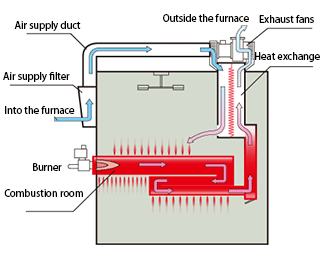

Drying method

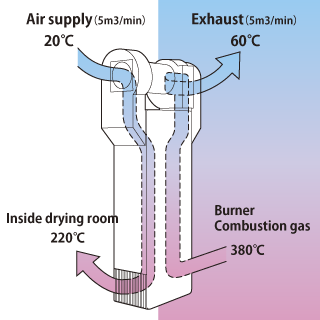

DRYTECH is a hot-air drying system that recovers exhaust heat.

Unlike direct-fired dryers, it is an indirect heating system that warms the inside of the furnace to dry workpieces.

High-efficiency heat exchanger

The exhaust heat from combustion is exchanged with the air supplied to the furnace at a heat exchange rate of approximately 85%. The furnace is heated with the necessary heat combustion energy, thus enabling drying without wasting energy. In addition, the furnace is constantly supplied with fresh and abundant oxygen, allowing drying without filling the furnace with evaporating paint gases and preventing coating defects such as gas checking. This is especially effective in preventing yellowing defects in white paints.

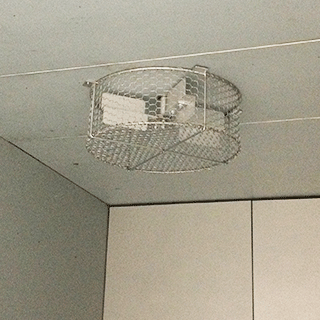

Furnace fan

Maintains a constant temperature distribution inside the furnace without irregularities.

DRYTECH GO-2522 Internal Dimensions

Frequently Asked Questions

Does the hot air method cause garbage defects?

Defective garbage is basically caused by bringing garbage into the furnace. Therefore, it is important not to bring garbage into the furnace to prevent garbage defects. One of the most common causes of garbage defects is when the cart that carries the workpiece into the furnace is covered with a lot of garbage. It is advisable to clean the substitute cart and jig by air blowing, etc.

Can it be installed in a clean room?

Of course, it can be installed. The inside of a coating room must be kept clean to ensure good quality. DRYTECH uses an indirect heating system, which means that the seed fire does not enter the furnace. Therefore, it can be installed in a clean room.

Do we need a pit for the burner or a ramp for the dolly?

None of these are required. The burner is connected to the combustion chamber next to the dryer. The heat from the burner heats the combustion tube in the combustion chamber and passes through a heat exchanger to the outside of the furnace. Since the inside of the furnace is heated by the heat from the heated combustion tube, the seed fire does not enter the furnace and can be safely converted.

The floor plate is made of 3.2 mm steel. The cart can be smoothly transported into the furnace. Slope is not included.

DRYTECH Options

For small amounts of drying Partition board

The partition board divides the furnace on the left and right, allowing one of the two units to be used as a drying furnace.

Since the generators are located on the left and right sides of the furnace, when drying a small amount of workpiece, the partition plate is used to divide the furnace and allow one of the generators to operate by combustion, thereby reducing wasted energy consumption when drying a small amount of workpiece.

DRYTECH GOW-2522 Outline drawing

DRYTECH GOW-2522 Outline drawing

GO-2522 Inner dimensions

| Dimensions | 2500 mm × H 2465 mm × D 2160 |

|---|

Options / Related Products

Partition board

2023.03.24