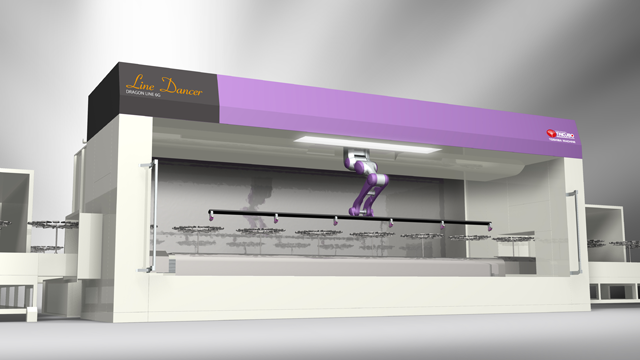

LINE DANCER®(LINE DANCER)

Coating Robot for Mass Production

The Best Standard for Smart Phone Coating

Realized the best coating film required for smart phone

Is there any good coating method for explosive spread of smart phones? TAKUBO gives the best answer to that problem.

We have the technology that we have cultivated in developing mobile-phone coating systems. Now improving that technology furthermore, finally we have completed an ideal coating robot. Making a load capacity of 20kg for the robot, we realized the world-biggest production volume by one robot with maximum 12 guns. In addition, we have connected our R-technology with a concept of coating in a stop while stopping the line. DRAGON LINE with the accumulation mechanism installed on the both sides of the robot provides the system with high quality and reduction of energy cost.

Realization of high-grade super luster coating film

R-technology, revolving coating, produces much higher-grade luster coating-film than glossy performance called Piano Touch.

High effective mass-production with low cost

Wasted coating material consumption is reduced by max 12-gun mounting robot, syringe pump system with super precise coating material supply function, gun control, and robot teaching. Both reduction of energy cost and mass-production also become realized by setting a high effective DRAGON LINE.

Downsizing of a facility

DRAGON LINE prevents the booth from becoming bigger in spite of 12 guns, and brings downsizing of a facility.

World-biggest class and Downsizing

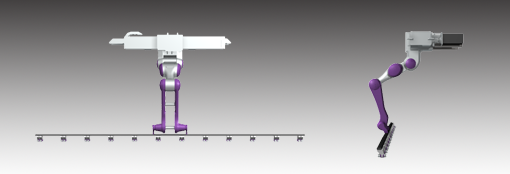

Robot arm

Conventional robot has changed powerful and also progressed elegant.

- Max 12 guns with the load capacity of 20kg

- Pressure-resistant and Explosion-proof specification

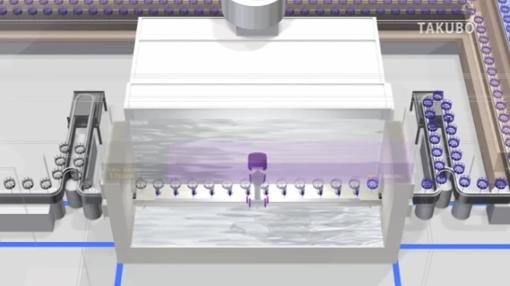

DRAGON LINE

DRAGON LINE coating means a mechanism in which work pieces on the conveyor-line stop while they are coated in the booth. It prevents the booth width from spreading even though the number of guns increases. It also makes the supply and exhaust air-volume lower, and saves the energy cost.

- Downsizing of a coating system

- Reduction of energy cost

- Realization of high-grade coating

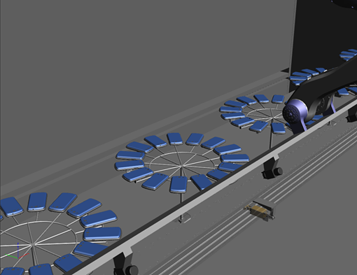

1. Super luster coating film type, LINE DANCER

Specification to produce the highest-grade performance such as super luster film for smart phones

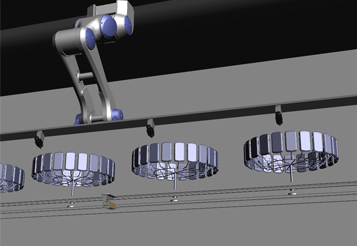

Placing 15 work pieces horizontally in a radial pattern, the super luster film with thin multi-layer is completed by R-technology, revolving coating.

◎Coating data

Number of work pieces per ring :15pcs/ring

Coating time per ring :40sec/ring (about 2.6seconds per piece)

Coating material consumption per piece :2.3g/pc

- Design of jig exclusively for revolving with horizontal placing

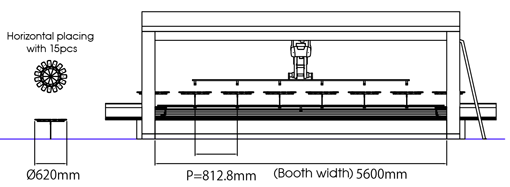

Jig for smart phones to place horizontally - Drawing of LINE DANCER with horizontal placing specification for super luster coating film

Drawing of LINE DANCER with horizontal placing specification

2. High-grade coating film and mass-production type, LINE DANCER

Specification to mass-produce the high quality performance films for smart phones

Placing 22 work pieces vertically in a radial pattern, the super luster film with thin multi-layer is completed by R-technology, revolving coating.

◎Coating data

Number of work pieces per ring :22pcs/ring

Coating time per ring :60sec/ring (about 2.7 seconds per piece)

Coating material consumption per piece :2.5g/pc

- Design of jig exclusively for revolving with vertical placing

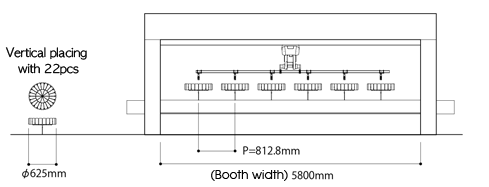

Jig for smart phones to place vertically - Drawing of LINE DANCER with vertical placing specification for mass-production

Drawing of LINE DANCER exclusively for vertical placing

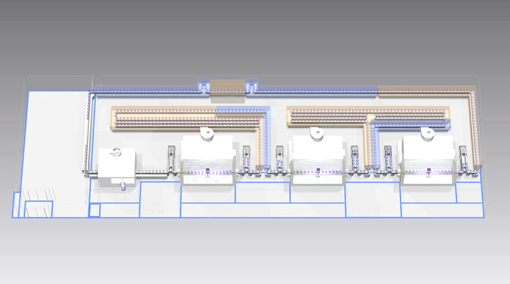

Example of 3 Coatings by 3 Robots

System example of 3 Coatings by 3 Robots of LINE DANCER

Production volume:158,400 pcs (Production time:20 h

LINE DANCER, coating robot

| Configuration | Ceiling-suspended multi-joint type | |

|---|---|---|

| Driving method | Pressure-resistant and Explosion-proof | AC servo motor rotary drive |

| Motion axes number | Four axes (including overrunning axis) | |

| Position repeat accuracy | ±1mm | |

| Max speed | 500mm/sec | |

| Wrist unit | ||

| Setting pose | Vertically ceiling-suspended style | |

| Ambient Temp and Humid | 0℃〜40℃ | 85%RH |

| Arm weight | 68kg | |

| Loadable capacity | 20kg |

Options / Related Products

Oil BoothLink to product page

Booth designed for long life and low noise using oil as cleaning solution

DATA-PROLink to product page

Robot to make exclusively coating data including color matching, shortening of coating time, reduction of coating material consumption, teaching and so on

DRAGON LINELink to product page

TAKUBO’s original conveyor line exclusively for coating with high effective accumulation mechanism

LINE DANCERis a registered trademark of TAKUBO ENGINEERING Co., Ltd.