Data capture(SWANIST)

Teaching assistant software

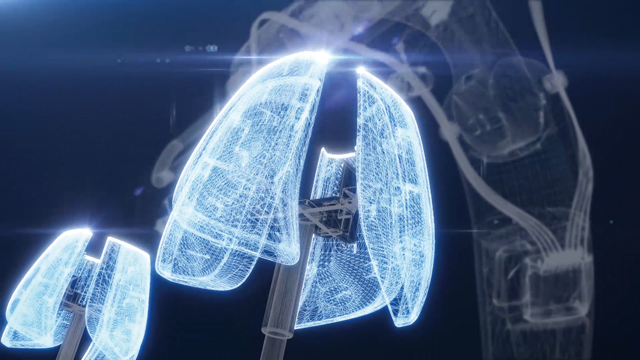

Workpiece data is captured and converted to 3D. The optimal mounting position, angle, and number of pieces are digitized.

Offline teaching with SWANIST begins with workpiece data capture. The position, angle, and orientation of the workpiece, placed in a ring, are all digitized and stored.

Workpiece information capture

Capturing 3D data of workpiece

Workpiece data is captured and a 3D workpiece is generated. The workpiece is placed in the virtual space, and the preparation before teaching is complete.

Preparation before teaching

- Capturing workpiece data Converting to 3DCG

- Determine the orientation, angle, and number of workpieces to be placed

The quantity is determined in light of the distance between workpieces when placed and installed in a circular ring.

Place the robot so that it fits within the specified perimeter (yellow cylindrical perimeter guide). Also, place the robot in a way that its movements are simple and not complicated. The key is to place the robot in such a way that it does not make unnecessary movements.

Key points for workpiece placement

- Keep within approx. 400 mmφ perimeter (yellow cylindrical guide).

- Workpieces should not be placed too close to each other. Place the workpieces at an interval that does not interfere with each other during revolving coating.

- Position the robot so that there is no waste in its movement (set the angle).

Jig Design

- Output information using the workpiece placement information output function

- Requests jig manufacturers to manufacture jigs based on 3D design jig data.

Freedom from analog jigs

Instead of designing the jig and starting the teaching process, the workpiece is simulated in a virtual space and the jig data is output.

Consideration is given in advance to the mounting angle at which the robot can be easily coated, the reasonable number of pieces to be mounted, the ease of removal and attachment work, and a structure that prevents dust from adhering to the workpiece.

Simplifies jig design

- Rational jig design

- Advanced jig development through workpiece placement in accordance with teaching

- Improvement of coating cost Appropriateness

Workpiece placement example

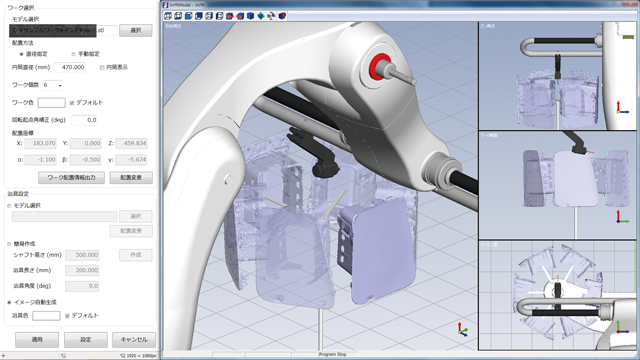

Example Car navigation frame

Workpiece name: Car navigation frame

- Size: 440φ

- Number of installations: 4 pieces

- Material: Resin

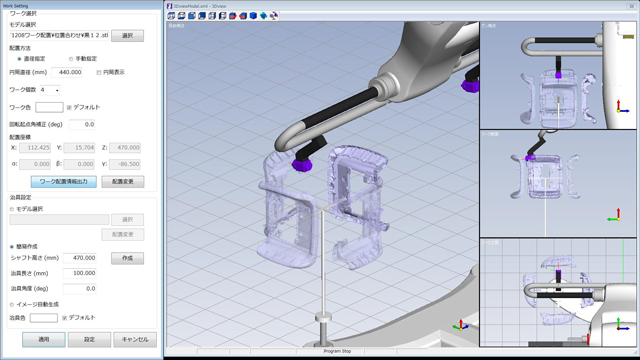

Example Steering center cover

Workpiece: Steering center cover

- Size: 470φ

- Number of installations: 6 pieces

- Material: Resin

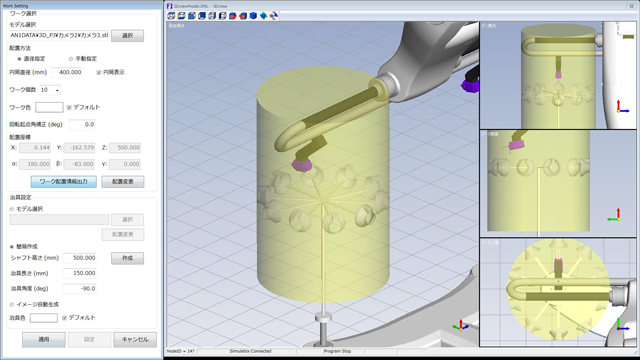

Example Camera parts

The 400φ cylindrical display (yellow) makes it easy to visualize the revolving coating.

Workpiece name: Camera parts

- Size: 400φ

- Number of installations: 10 pieces

- Material: Metal

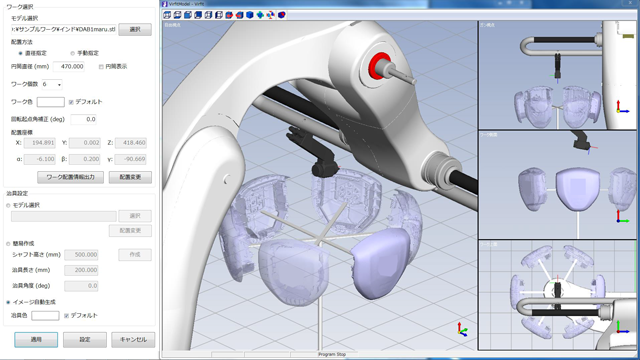

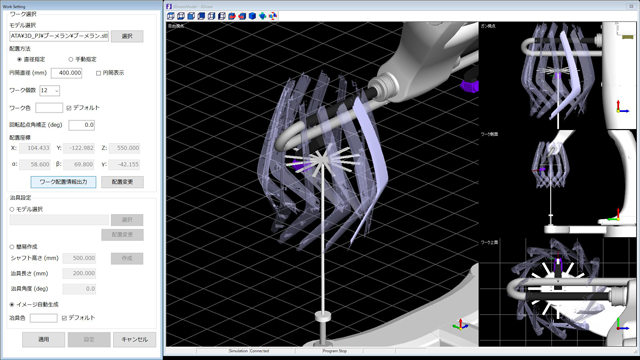

Example Automobile exterior parts

Example of mounting a boomerang shaped workpiece.

Example of thin workpiece with distorted shape. Horizontally angled placement enables efficient coating.

Workpiece name: Automobile exterior parts

- Size: 400φ

- Number of installations: 12 pieces

- Material: Resin