DISK PACK

【DISK PACK】, software specialized in revolving coating, is developed to reduce the teaching time and to pursue the reduction of paint consumption volume. It is also designed to make a precise reproduction including coating conditions.

【DISK PACK】, software specialized in revolving coating

SOFTBOY series coating robots have fulfilling software to support teaching work. “DISK PACK”, a dedicated software for revolving coating, is very useful to coat relatively flat work components with horizontal placement.

DISK PACK Teaching Software 【DISK PACK】

DISK PACK Coating (DP Coating)

DISK PACK Coating (DP Coating)

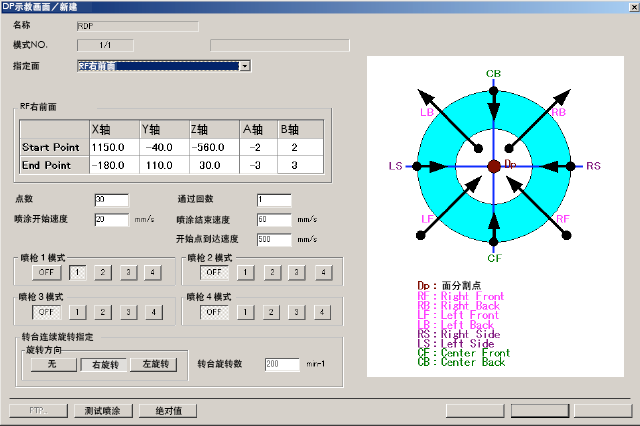

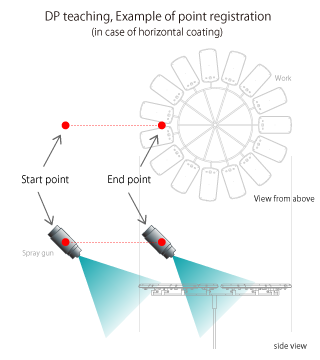

- In case of revolving coating with horizontal placement, coating gun speed and other conditions should be adjusted because of peripheral difference between inner and outer. In this software, only input of 2 points of Start and End points will automatically make an appropriate coating data with suitable coating speed between the two points.

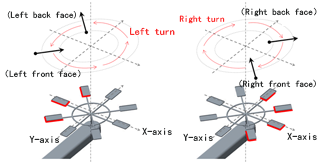

- Coating data for the 4 faces divided by X and Y-axes are so symmetrical that you can make them easily by converting the data on PC.

- DISK PACK (DP-PACK) is a software to be good at revolving coating with horizontal placement. What you do is basically just to input only 2 points of Start and End. Coating data can be completed by adjusting spray conditions and turning directions in order.

Easy point registration by moving robot to the point which you want

- Point registration is made by moving the robot to the points which you want in the remote mode, PTP (Point To Point Teaching Mode). It is a very easy teaching work because you do not have to edit any programming language.

- PTP mode can make edit/revision/registration for subtle correction. Or it is possible to revise the point data by inputting values directly on the screen for creating new. You can make a direct operation in both remote and input.

- Information about robot position is always displayed on the screen so that you can confirm the current robot registration positions immediately. Work efficiency and time are improved very much.

Spray conditions can be registered at the same time, and coating cost is also calculated automatically.

- You can make both robot track teaching and spray condition setting at the same time.

Easy input of both teaching data and coating conditions - It is possible to easily revise the spray conditions by inputting values directly after coating trial. There is no need of difficult work to make pre-registration, which used to be necessary in conventional teaching software. If you need to change the conditions for some change of environment or paint, you will be able to respond immediately.

- Of course, easy registration to make a list of condition settings

- Input of paint prices (main material, hardener and thinner) and mix ratio in the coating specifications will display the coating cost by calculating with coating time and used material volume after coating operation.

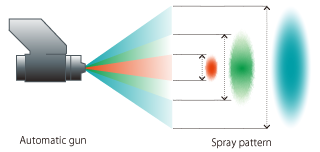

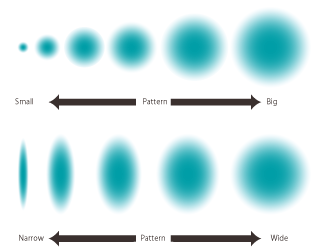

Possible to set spray patterns according to specific work shape and paint.

- Possible to finely set spray conditions also for complicated uneven parts.

- Pattern setting depends on the state of work surface, for example, the wide and large spray pattern should be set for wide face of the work, and the narrow and small pattern should be set for uneven part.

A series of teaching operations becomes so simple that the total operation time can be significantly reduced.

- DP-PACK makes the time for a series of the operations from teaching to trial coating to be significantly reduced.

Image input is possible. - Because pictures of the work is possible to register, you can save and manage coting data with work pictures.

- Registration of the created data is also very easy so that you can make a list of them. Making a backup data in other media, you can make a safe operation at ease.

Registration and management of image are possible.

Reproducibility of the data is extremely high, and also data sharing is available.

- The registered data can be reproduced in an every robot of the SOFTBOY PRO series promptly just after easy position adjustment.

- Teaching data sharing among the scattered factories becomes possible so that the stable quality coating production can be available without any variation in quality.

Data sharing and management are possible among the factories scattered around the world.

公開日:2017年4月10日