SWANIST(Teaching Assistant Software)

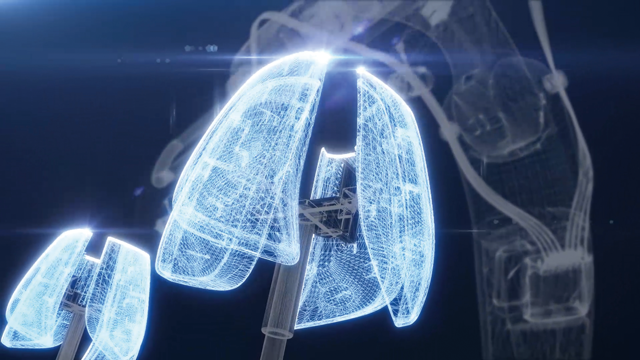

Digital twin

DTT / Desk Top Teaching Enabling the Desk Top Teaching.

“ SWANIST ”, an offline teaching software that goes beyond the level

Enables centralized management of coating from data creation and management to cost calculation

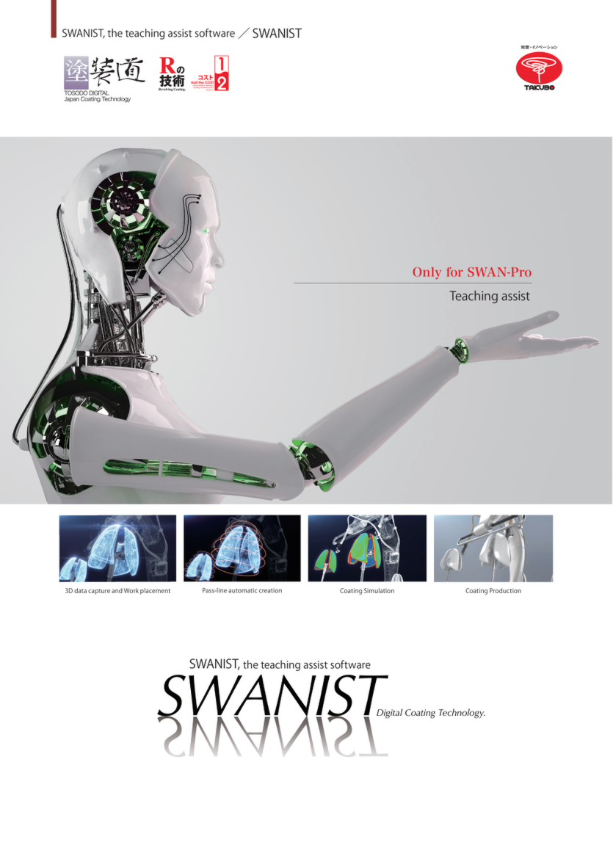

SWANIST is a teaching assistant software for revolving coating "R technology" that simplifies teaching of coating robots and realizes realistic virtual coating with condition settings. Teaching work is managed numerically. From workpiece data capture to 3DCG generation. Optimal teaching, including placement on the revolving jig and the amount of paint used, is all digitized. In addition, the viewer application and coating cost calculation application enable centralized management of coating operations, from management to cost calculation.

Lineup

-

Data captureSWANIST

Teaching assistant software

Teaching assist

Workpiece data is captured and converted to 3D. The optimal mounting position, angle, and number of pieces are digitized.

-

TeachingSWANIST

Teaching assistant software

Teaching assist

Digitization of teaching tasks Automation of teaching

-

Virtual coatingSWANIST

Teaching assistant software

Teaching assist

Realistic reproduction and verification of coatings in a virtual space significantly improve quality, cost, and work environment.

-

Automatic coating data generation and sharingSWANIST

Teaching assistant software

Teaching assist

From workpiece data capture to coating simulation, all processes are numerical.

-

Coating cost calculationSWANIST

Coating cost calculation application Japanese version

Teaching assist

Easily calculate coating costs

-

Other functionsSWANIST

Coating cost calculation application

Teaching assist

Versatile functions of the coating calculation application

Everything is Digital Twin for Coatings

Digitalization of coating

The important basic operations of coating production by the robot are 1) teaching, 2) Setting paint conditions, and 3) jig design for workpiece placement. These three operations to complete coating production. SWANIST is teaching assistant software developed to digitize and automate these settings.

By digitizing these operations into a numerically manageable digital format and reproducing them in a real 3D virtual space, a series of operations can be simplified, converted into highly reproducible data, and transferred to the coating robot system to enable automated production. This enables automated production.

Essential work items for coating production by robot

- Teaching

- Setting paint conditions

- Jig design for workpiece placement

Simplifies tasks that require expertise

Each of these tasks requires expertise in 1) teaching, 2) setting paint conditions, and 3) jig design for workpiece placement. SWANIST" takes care of all these tasks using the latest digital technology.

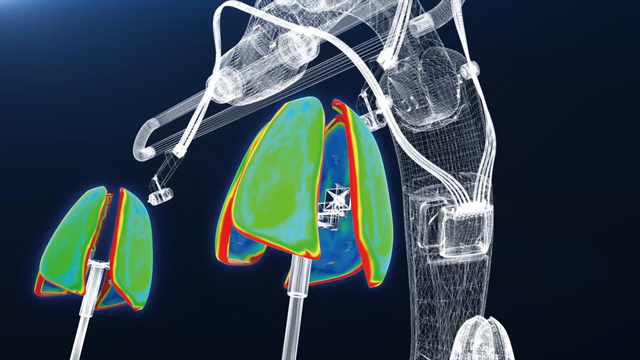

More accurate coatings are played out in virtual space

Workpiece data capture

Workpiece information import

- Read in 3D data of workpiece

- Calculate the optimum number of workpieces to be installed per one jig (ring)

- Design of jigs and workpieces

Teaching

Virtual teaching

- Paint conditioning

- Teaching considering gun distance

Coating demonstration

Virtual coating simulation

- Film thickness check Coating check

- Confirmation of coating time

- Virtual final check before full production

Coating production

Data preparation and transfer

- Storage of coating data including teaching data

- Transfer to DATA-PRO and other coating robots (SOFTBOY-PRO, LINE DANCER, SWAN-PRO)

- Real coating test

- Real production Start of coating production

SWANIST workflow

SWANIST aims to virtually automate the entire process, from data capture to automatic teaching, analysis, and data conversion. SWANIST is also advancing the IoT of coating with its "SWANIST Viewer" application, which allows users to check and manage coating, operating status, and remaining paint levels.

Effect of SWANIST

- Improvement of coating operations

- Improvement of coating cost

- Quality control

- Environmental responsiveness

- Creation of coating profits

- Promotion and rationalization of digitalization

- Education and training of coating robotics personnel

- Hope for the future