Hose-less Coating Robot 2018(Hose-less Coating Robot 2018)

Development of a coating robot system that eliminates the paint hose

Development to eliminate paint loss such as reduction of unused paint remaining on the hose and cleaning solvent

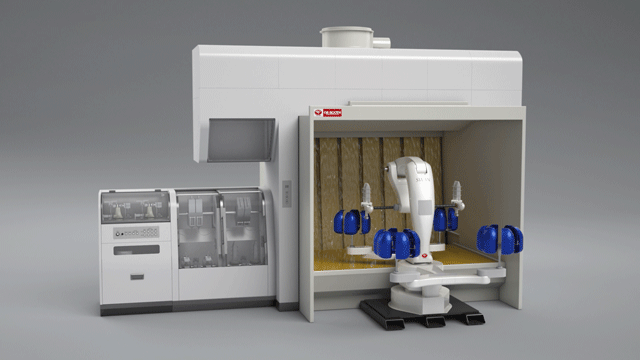

Hose less coating robot system 2018 development product

This is a coating robot system without paint hose. The paint & spray part and the robot are separated. Since there is no paint hose, the amount of wasteful paint used is reduced to the utmost limit. In other words, it is a coating robot system that realizes high-quality, low-cost coating using the revolving coating R-technology. (Highly functional PAINT & COATINGS EXPO 2018 exhibition development product)

Flow of hose less robot system development

Hose less Robot System 2006

Exhibited at SURTECH & Coating Japan 2006 How to shorten the paint hose, developed for revolving coating of two-fold mobile phone parts

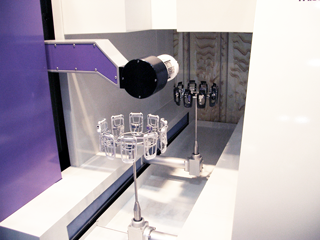

Syringe gun

The syringe pump and spray gun were combined and the paint hose was eliminated.

A syringe gun is attached to the tip of the robot arm.

Hose less Robot System 2010

2010 Development of the first hose less gun with a syringe pump unit connected to

Exhibited at Toshiba Machine Group Solution Fair

Syringe Gun 2 Hose less

The syringe gun 2 uses an air shooter to fill and transport paint in the paint room.

It is loaded into the robot arm.

Hose less robot system 2018

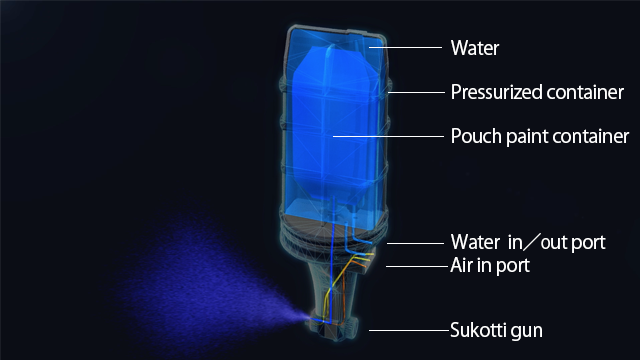

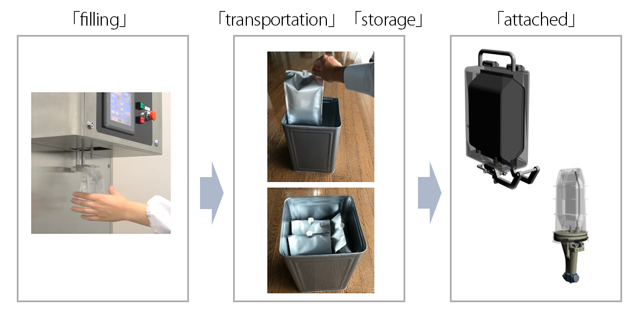

2018 Changed the paint tank to a pouch container. We have developed a mechanism that discharges with water pressure and applies atomization pressure and pattern pressure (air) to the automatic spray gun side.

Exhibited at Highly functional PAINT & COATINGS EXPO 2018

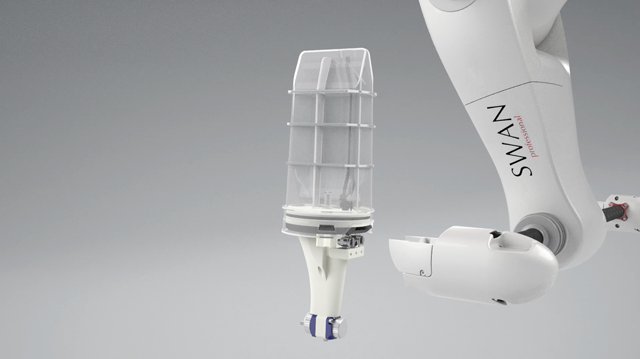

Hose less gun

Handling performance has been improved by changing the paint tank to a pouch container.

Lighter weight than conventional hose less guns. In addition, we have also developed a mechanism for filling paint.

Automation from filling to coating, transportation and cleaning.

Features of Hose less Robot 2018

Development purpose

A highly efficient robot-based coating system that reduces paint waste loss.

・Reduced the waste loss of unused residual paint remaining on the paint hose. In addition, the time for color change and setup change is shortened, and work efficiency is improved.

・Improvement of industrial waste treatment amount coating technology treatment cost

・Conservation of the global environment

・And optimization of coating production profit

Features

- Coating system using a newly developed hose less gun

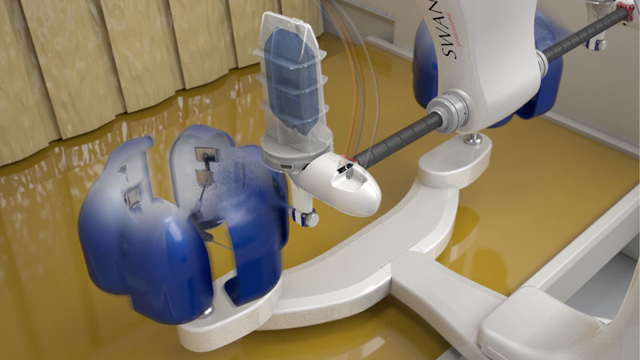

- A coating robot system that combines a hose less gun and an improved SWAN

- Systematized paint filling, transportation and cleaning of hose less guns

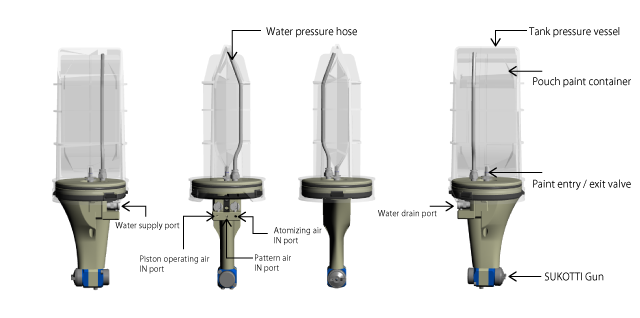

Hose less gun structure

The spray gun, which was developed to eliminate the paint hose, is designed with a paint tank and spray gun integrated into a paintable mechanism.

The pouch container has been improved as a paint container, and it is placed in a pressure-resistant container and sealed. Water pressure is applied to the inside of the tank, pressure is applied to the pouch paint container, and then the paint is discharged.。

Coating system Hose less gun and SWAN robot

The hose less gun changes the gun from the booth ceiling via the transport device. Color changes and setup changes can be performed quickly, and by eliminating the paint hose, unnecessary paint loss is reduced to the utmost limit.

Hose less gun compatible A specially designed SWAN robot goes to pick up the hose less gun and replaces it.

The air hose and hydraulic hose can be separated. Structure that 5 ports are removable.

The hose less gun docked to the SWAN robot performs the "R-technology" revolving coating. Achieves multiple high-quality coating production of thin films.

The teaching method and condition settings for the SWAN Robot remain the same as before. Data will be created by a SWANIST.

Paint filling cleaning system

We have also systematized the filling and cleaning of paint on hose less guns. Simply set the pouch paint container containing the paint and fill the hose less gun. It also enables cleaning of the Sukotti gun.

It is systematized without the paint solvent scattering. The paint constantly gives a slight rotation and vibration to the pouch paint container to prevent it from settling. The collection of cleaning agents is also designed in the system.

Easier to change colors. Eliminates unnecessary paint loss and handles paint compactly. The work time is also greatly reduced, and painting production can be done without delay. It also reduces the burden on workers.

Paint delivery concept

By changing the paint container to a pouch paint container, the surrounding area becomes simple and compact.

- Simple filling of pouch paint containers. It is filled with the minimum required paint.

- Transport is carried by putting it in a metal container such as an 18-liter can. (Transportation of dangerous goods, Fire Service Act in Japan) Storage is also easy with the minimum necessary.

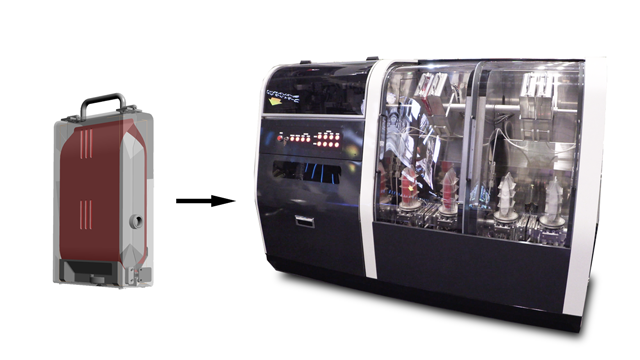

- Paint is put in a special cartridge and loaded into a One-cup system or an automatic filling device.

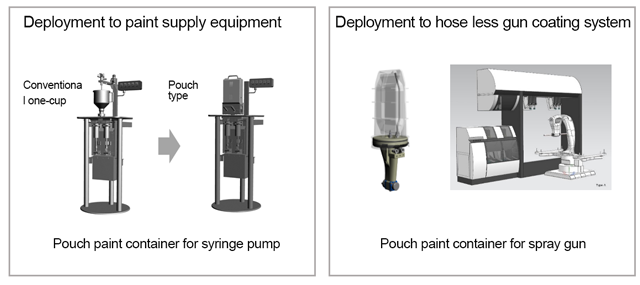

Deployment of pouch paint container One cup system and hose less gun

Remodeled the one-cup system and painting robot system into a dedicated paint filling device.

- The paint filled in the pouch paint container is sent to a paint supply device such as a one-cup system.

- To the paint filling device of the coating robot system

Hose less coating system

Hose-less robot is under development.

- Hose-less robot was exhibited as prototype at Coating Japan 2018.

- Hose-less robot is under development and not for sale.

- If you are interested in it, please visit the inquiry page in our TAKUBO web site.

- Hose-less gun: The spray gun device for coating is a patent of TAKUBO Engineering Co., Ltd.

- Hose-less robot: The paint filling unit and the paint filling device equipped with it are patented by TAKUBO Engineering Co., Ltd.

TAKUBO Engineering Co., Ltd. pursues coating systems for a sustainable future and supports SDGS through TOSODO, our company’s spirit.

July 20, 2021