Smart Phone 3R3C Example

【Smart Phone 3-Coating by 3-Robot】

Best Standard for Smart Phone Coating

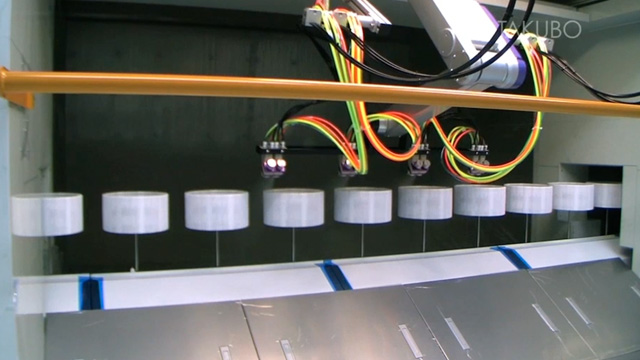

3 robots of SOFTBOYPRO with 4-gun (2×4) are set up. 3-Coating by 3-Robot System to make 3 coatings for Smart Phone

SOFTBOYPRO/ Super Spindle 300C Coating System, all of the parts such as Robot, Spray guns, Conveyor with revolving mechanism, Controller, Booth and Syringe pump, is controlled together. We have brushed up our technologies, which we gained in our mobile phone coating development, to meet Smart Phone Coating. Furthermore, we have introduced the new developed conveyor line with accumulation mechanism, DRAGON LINE, to realize a mass production with much lower cost.

Features

Reduction of coating cost

Reduction of coating material consumption

Coating material consumption per one piece is substantially reduced by the revolving coating technology with multi-layer thin-film coating.

Mass production

Mass production

Mounting 4 guns on one robot can increase the processing capacity of one robot dramatically to realize a mass production with low cost.

Low cost production

DRAGON LINE, the conveyor line with the accumulation mechanism, makes the booth width the shortest. It means reduction of air-supply cost and contributes to the lower coating cost.

Specifications / Performance

Precise control of coating material

Precise control of coating material volume by Syringe Pump

Syringe Pump with 4-gun spec, TAKUBO’s original coating material supply system, which can control in 1 cc increment, reduces waste coating material consumption.

TAKUBO started developing fixed quantity supply of coating material in an earlier time by using a syringe pump in the coating material supply device which was called a heart of coating.

Conventional pressurized feeding method had already reached limit in reduction of coating material consumption and coating cost. A new coating material supply device to control more precisely was necessary to adopt multi-gun coating method in order to realize a mass-production with low cost. Precise control of coating material and high quality with low cost are strongly combined with each other.

Revolving Coating

High quality coating by R-Technology with revolving coating

Original conveyor line with CW/CCW revolving is installed in the robot. The robot makes a coating with appropriate paint volume in controlling the number of revolving.

Measure against inferiority

Clean room as a measure against dust inferiority

- Coating system is designed to be cleaned by class 100,000, and also to be with temperature control system. Especially the coating area, where SOFTBOY PRO is installed, is designed to be a clean room always cleaned by class 10,000. Measures against dust/seeding inferiority are fully taken.

Clean room (left), Dust-elimination robot (right) - Setting dust-elimination booth and booth prevents dust inferiority.

- Pass box prevents invasion of dust and seeding which people bring.

DRAGON LINE

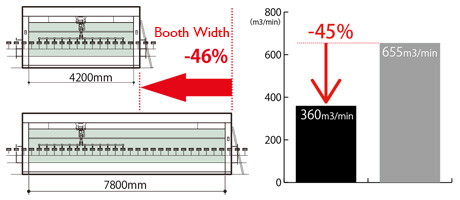

DRAGON LINE is a conveyor line installed accumulation mechanism, which Takubo developed exclusively for coating. It has accumulation mechanism parts on the both sides of the robot.

A robot with multiple guns will naturally need a wider booth. This is the reason why the structure of robot is a work-following type while the conveyor does not stop in coating.

The feature of SOFTBOY PRO, ceiling-suspended coating robot, can realize a great mass production operation by mounting with multiple guns. However, a necessary wider booth will increase the air condition cost at the same time.

A new mechanism has been developed that a robot coats while the conveyor stops in the booth. That is named DRAGON LINE.

Stopping the conveyor in the booth for a while deletes robot moving and makes the booth width shorter. In result, the problem of air supply cost increase has been resolved.

Reduction of air supply cost

- Compared to the robot following type, there is almost no robot moving to left and right, and the smallest size of the booth is realized.

- Compact booth

- Miniaturization of the facility

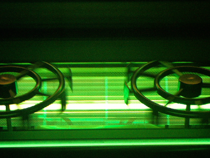

UV Coating, UV irradiation line

- Coating line is designed based on our experience and know-how since Takubo introduces UV coating system in the coating industry at an early stage.

- Original UV irradiation line such as solvent dryer or cooling zone, which are suitable for revolving coating, is developed and designed.

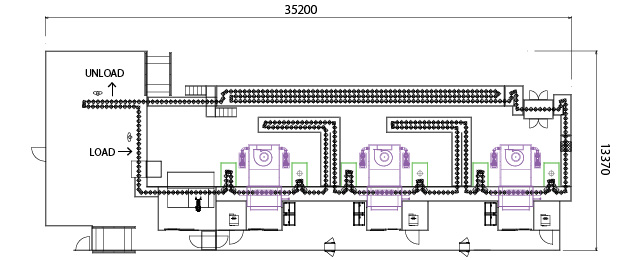

Reference Layout

Smart Phone 3-coating System

Specification

| Coating material consumption | 8pcs | Work mounting number per a circle jig |

|---|---|---|

| Gun number | 4guns | per 1 robot |

| Work name | Smart Phone Cover | Smart Phone Body Cover |

Capability

| Coating time | 1.25sec / p | Smart Phone Body Cover |

|---|---|---|

| Coating material consumption | 5cc / p | Coating material consumption per 1 work piece (1 coating) |

| Production volume | 2,880pcs / h | (Production volume per one hour) |