One Cup System(Paint supply system)

Cup Refill Type Paint supply system

“Only the necessary amount needed”

“Only the necessary amount needed”. It realizes a precise paint consumption without any waste by high-grade control system. Small size explosion-proof motor and high-grade Syringe pump to control in 1cc unit are installed as standard equipment. One Cup System is a standard equipment of paint supply system for SWAN Robot.

One Cup System

One Cup System is a paint supply system exclusively for SWAN Robot. Cup refill method is adopted to avoid any waste of paint consumption and to control precise paint supply amount. It has been developed to finally realize a low-cost coating production.

① Paint supply system with compact design

② Accurate fixed volume supply of paint without any pulsation

③ Easy cleaning and maintenance

④ Reduction of waste paint consumption

⑤ Pressure-resistance and Explosion-proof motor is used to increase safety.

Features

Easy work with Cup Refill Type

Setting of paint is the Cup Refill Type to refill only the necessary amount needed. The cup size is the maximum 4 liters.

High grade collaboration between the robot and the switch panel

Knob switch is used to feel a sense of work. Manual operation and automatic mode are available. It works in collaboration receiving a signal from the robot. Cleaning work is also semi-automatic, and its time is reduced by connection with Quick cleaner.

High precision syringe pump with explosion-proof motor is equipped.

Super small explosion-proof motor, which was developed in our robot development, is adopted. Safety use even under explosion-proof environment is confirmed. Syringe pump to control in 1cc unit can contribute to good quality of coating film by avoiding waste paint consumption and supplying the paint precisely without any pulsation.

Mixing function is also fulfilled.

Bone material containing paints, sedimentary paints, 2K or diluted paints are acceptable to mix.

SUS tray is safe even if the paint spills.

The vessel type tray is made of SUS so that it is safe even if the paint spills. Peripheral pollution is prevented. Also it is useful as parts storage space in maintenance work.

Paint cup is easy to install and remove.

Screw type only to twist the cup is very easy. You can install and remove the cup easily with one hand.

Special Teflon coating is easy for cup cleaning.

Solvent resistance special Teflon coating is made for the inside of the cup. It is very effective in cleaning the remained paint so that waste consumption of the solvent is reduced.

Quick cleaner can realize a high-speed cleaning.

Quick cleaner with high-pressure compression pumping tank cleans the remained paint in the circuit of the hose and the spray guns in a very short time.

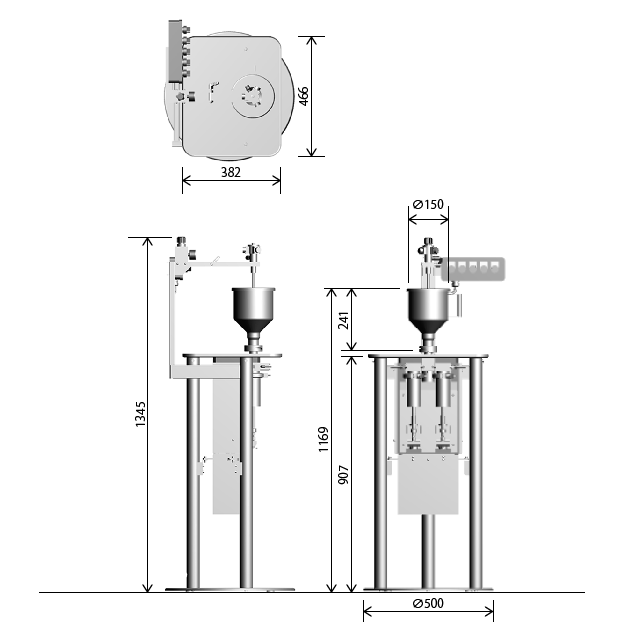

Dimensional drawing of One Cup System

Specifications of One Cup System

One Cup System Model: SP15EXP-100Y-2

| Drive method | Ball screw driving | |

|---|---|---|

| Cup capacity | 2L | Cup |

| Table size | W382/D466/H1345 | Table size |

| Number of syringe | 2 | |

| Capacity of syringe | 100cc | |

| Syringe material | SUS304+Special Coating | |

| Piston stroke | 80mm | |

| Piston material | SUS304 | |

| O-ring material | Special rubber | |

| Connection diameter | PT G1/4Output | |

| Drive motor | Pressure-resistance and Explosion-proof AC Servo Motor 200W | |

| Drive Amplifier Model | VLPSX-008P2-SBA-0301 | by TOSHIBA MACHINE |

| Valve method | Air operated system | |

| Suction valve number | 2 | |

| Discharge volume | 30~100cc/min | |

| Explosion-proof type | Conformity :IEC60079-0& IEC60079-1 | ExdⅡBT4GbX |

One Cup System Standard Equipment Items

Standard Equipment Items

Syringe Pump System

- Syringe Pump

Quick Cleaner ※ there are some differences depending on the specifications. - Cylinder

- Cup container

- Mixer

- Quick Cleaner