SWAN Robot(Coating Robot)

SWAN, the coating robot is developed for the cost reduction.

SWAN is an independent type coating robot with W-turn inheriting R-technology. In collaboration with Teaching Assist function, much higher grade coating production will be realized. So to speak, IoT coating system will become a reality by easy off-line teaching with 3D simulation etc.

Lineup

-

What is SWAN Robot?Coating Robot

Reduction of running cost means the competitive coating technology. SWAN is the culmination of the revolving coating technology and the low running cost.

SWAN, the coating robot system to master coating

-

SWANCoating Robot

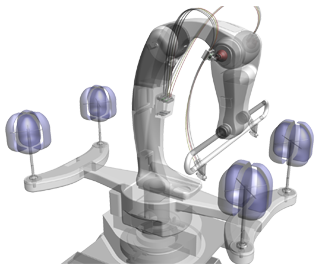

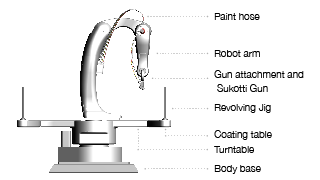

Independent type robot and W-Turn, both Takubo original, are combined. This is a compact coating robot system dedicated for R-Technology of Revolving Coating.

SWAN, Coating Robot System

-

SWAN-Ccoating robot for spindle type coating line

Coating robot SWAN pursuing coating technology

Coating robot born from ideas and innovation

To spindle lineSWAN-C is born, coating robot for spindle type coating line. For significant reduction in coating costs

-

SWAN-SCoating robot

SWAN-S is a type of SWAN robot without W-turn of handling device. Setting multiple set of SWAN-S on the line will make a continuous mass-production operation.

Possible to set on the line, the coating robot for mass-production

-

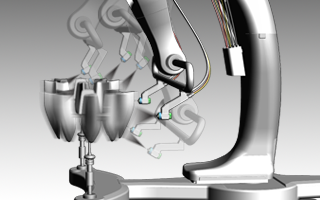

One Cup SystemPaint supply system

It is a paint supply system with Syringe pump developed exclusively for SWAN Robot.

Cup Refill Type Paint supply system

-

SWAN-application

SWAN is suitable for any kind of coating systems in a wide range, from manual to automatic methods. It is a coating robot to manage all coating system including coating trial, multi-kind and small-volume production and mass-production.

SWAN is very useful in every kind of coating system from manual to automatic one.

-

SWAN Extension AttachmentExtension Attachment for SWAN Pro

Extension Attachment for SWAN Pro It is possible to correspond to cylindrical workpieces such as lipstick cap, bottle, microphone etc.

Extension Attachment for SWAN

All for the cost.

Streamline form without any waste. Revolving coating production is completed by the 4-axis robot with 2 guns as standard equipment and the handling device of W-turn with rotation mechanism. What should we do in order to reduce the coating cost? SWAN Robot is an answer for the question since SWAN has the solutions to eliminate a lot of waste hidden in coating production.

Lots of waste hidden in coating production

It was not possible for a coating robot to solve all of the various problems in coating production. SWAN Robot has been developed to solve such problems.

Waste paint consumption / Waste solvent to use for cleaning / Waste stop of the line for color change operation / Waste coating time / Waste coating defects / Too much axes of the coating robot / Separate purchase of the necessary coating devices

SWAN the coating robot to challenge the cost

The imposed mission on a coating robot is to reduce the running cost. SWAN can realize the coating production to reduce the running cost based on the revolving coating of R-technology.

【 Pursuit of the revolving coating technology 】

Recoating in a little μm unit by multi-layer thin-film coating method in turning the workpieces CW and CCW.

【 Development of the device to reduce the paint consumption 】

Paint supply system to reduce the waste paint consumption by precisely controlling the paint amount in 1cc unit. It has a mechanism to reduce the cleaning solvent consumption for color change operation.

【 High grade collaboration control of the equipment 】

It is possible directly to set teaching operation or condition setting according to the workpiece or paint information so that the workability and the productivity can be improved.

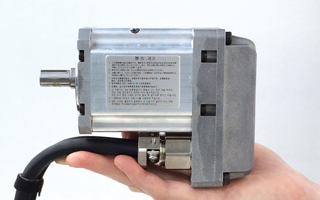

【 Development of explosion-proof devices 】

Development of the small size explosion-proof moto satisfies both safety and cost.

Types and options of SWAN Robot

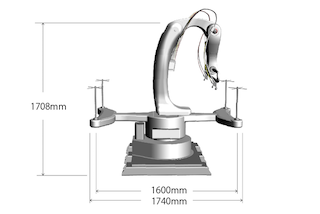

SWAN 1600-4TLink to product page

SWAN Robot standard machine with 1600mm diameter for the rotation range (Peripheral rotation range of 1740mm)

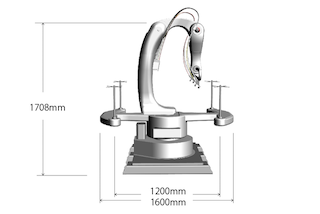

SWAN 1200-4TLink to product page

SWAN Robot standard machine with 1200mm diameter for the rotation range (Peripheral rotation range of 1600mm)

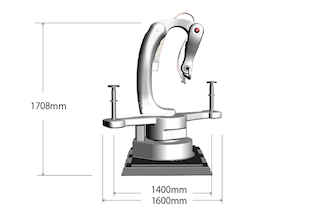

SWAN 1400-2TLink to product page

SWAN Robot standard machine with 1400mm diameter for the rotation range (Peripheral rotation range of 1600mm). It is suitable for rather heavy workpiece such as an automotive wheel in the revolving coating.

- For automotive wheel etc.

- Heavy items such as motor

SWAN SLink to product page

It is the SWAN Robot which is suitable for line operation. Good for continuous line operation of coating production because it does not have the handling device of W-turn.

- High cost performance

- Easy installation work

- Possible to start production immediately

CoSWANLink to product page

Explosion-proof type coating transfer device exclusively for SWAN Robot. It is made exclusively for coating.