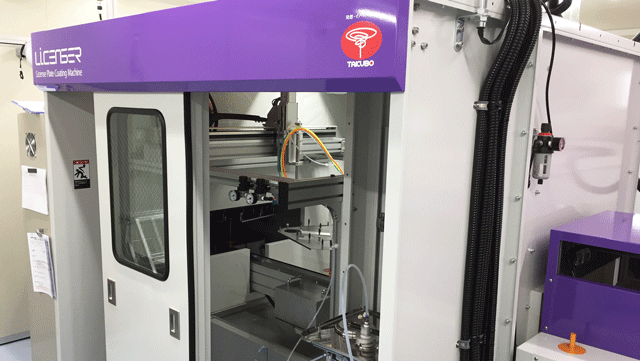

Other Coating Systems.(LICENSER)

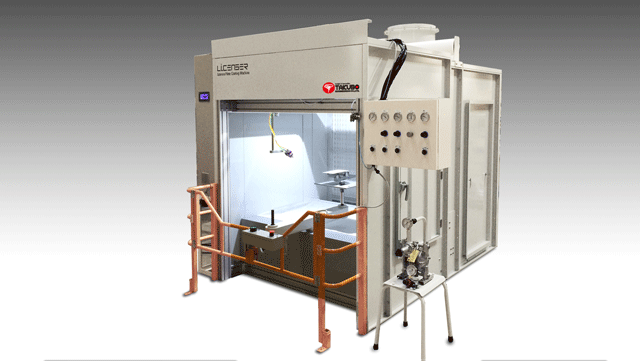

License plate coating system

Automatic coating system to coat aluminum number plates and license plates by revolving coating method

Automatic coating system for number plates

Compact coating

System to automatically coat automotive number plates by revolving coating method of “R-technology”.

Four number plates are mounted on a circle jig. They are delivered to the coating booth after passing in the dust removal and static elimination booth with automatic type “air jitter”. They are coated by the revolving coating and then delivered by the conveyor to the drying booth for baking.

It is a compact coating line that automatically coats number plates in the smallest space.

* Photos of the drying oven are omitted.

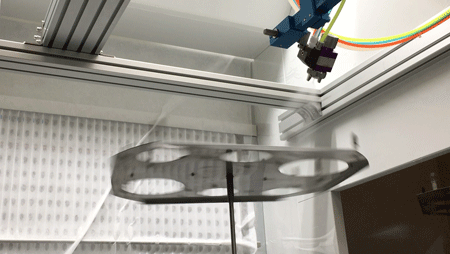

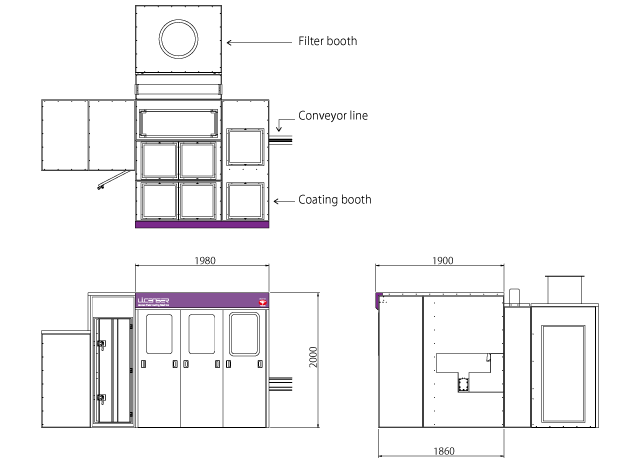

Coating booth

The straight 2 axes automatic coating system is equipped with one spray gun and coats while rotating the work pieces / jig in the forward and reverse directions. The coating time is about 60 seconds. Four number plates are coated within about one minute. (depending on required film thickness, paint features and son on)

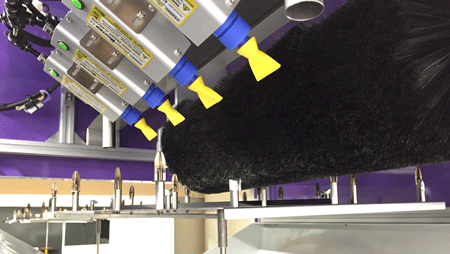

除塵除電ブース

Pre-treat for coating by an air gun with a static elimination ionizer and a rotating brush.

Dust removal and static elimination

Dust removal and static elimination of the work pieces / jigs passing in the booth with automatic “air jitter” on the conveyor with revolving function.

Handling equipment with revolving function

A forward / reverse rotation mechanism is designed in the coating booth of the conveyor line that is tact-fed, enabling uniform coating.

Demonstration of coating

The 2 axes straight device and revolving coating by SUKOTTI gun improves the quality. R-technology is very easy to make teaching and condition settings for spray gun. Numerical input reproduces quality coatings with the best film thickness.

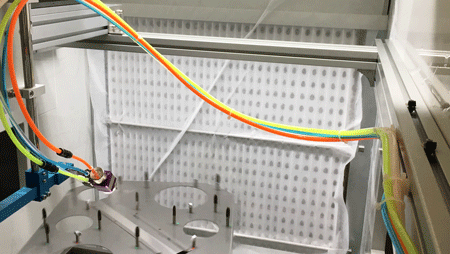

Filter booth

We are designing the best booth according to paint consumption volume and production volume. A roll-type high-density non-woven fabric is installed in front of the pleated craft filter, and the overspray is caught by the roll-in type roll filter. It is economical and reduces sludge collection and processing costs.

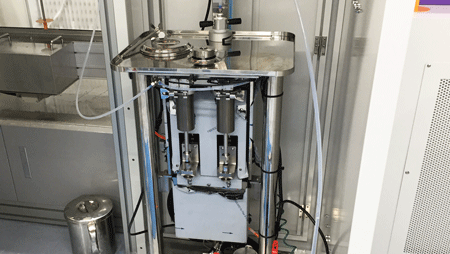

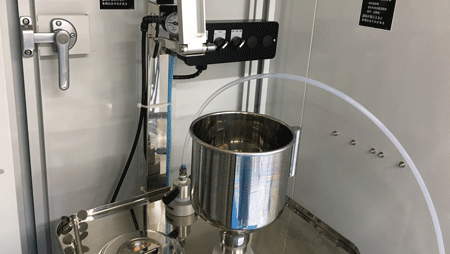

Paint supply system

The paint supply device uses TAKUBO Engineering’s Original Syringe Pump System for coating. Achieves coating with the optimum amount of paint used.

One-cup system

One-cup system is designed for paint supply system. One-cup system is integrated with Syringe pump and Cup type filling method. You can set the required paint as much as you need. Not using paint in vain. In addition, setting, mixing and cleaning are extremely easy, reducing the load of setting work.

Ceiling air supply filter for coating booth

Ceiling air supply filter for coating booth is adopted. Prevents turbulence of purified air and creates an air flow that does not affect coating.

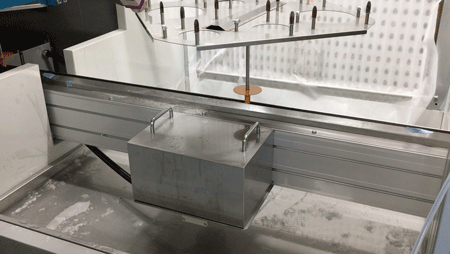

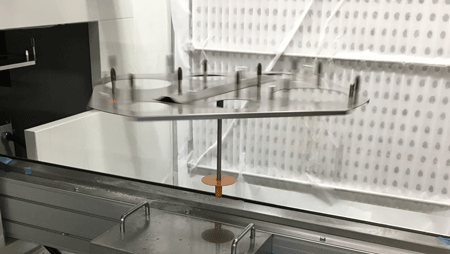

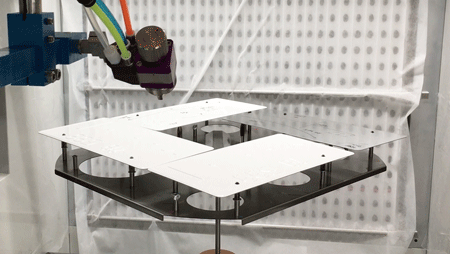

Rotating jigs

Work pieces are set horizontally. The most difficult thing about rotating coating is adjusting the film thickness at the center. With R technology, however, easy teaching is possible with the coating technology cultivated in the coating of mobile phones. With the advanced cooperation of the spray gun, coating device, syringe pump, and control system, four number plates are placed to realize horizontal revolving coating that enables uniform film thickness.

Example of work setting on rotating jig

Attach up to 4 number plates to the rotating jig, and rotate the jig together to coat.

Automatic coating system for number plates 「LICENSER」

Batch type coating system for number plates (reference)

It is a batch type number plate coating system where people handle the work pieces.

Reference drawing

Automatic coating system for number plates

Reference specifications for automotive number plate coating system

| Work dimensions | Small to large number plates, 125x230x2 | |

|---|---|---|

| Work pitch | 91,4mm | |

| Coating material consumption | 4 pieces/jig, in case of 700φ | |

| Coating method | 2 axes Straight type coating robot | |

| Coating time | 60 min/cycle time and dust removal/static elimination time | |

| Drying Time | 10min at 110〜120℃ | |

| Gun number | 1 | |

| Supported coating materials | 2K urethane paint (clear) | |

| Cycle time | 60min | |

| Processing Units | 1 jig | |

| Production volume | 60jigs/hour, 240pcs/hour |

Inquiry for number plate automatic coating system

Please contact the inquiry page for any questions about number plate automatic coating system.