Regarding the equipment for indium coating

In. Mirror Coating System

Q&A about coating and equipment

Q. What other equipment is required besides coating robots?

Can existing equipment be used?

A. A coating booth, drying furnace, clean coating room, and air conditioning system are required.

If the existing equipment is a Takubo type rotary coating system, it can be used.

However, a dedicated circuit must be installed for the middle coat (indium).

Q. Is it possible to downsize the coating system?

A. If the undercoat and topcoat can be UV paint, the coating facility can be downsized. We will design based on your paint, product, finish requirements, production plan, etc.

Q. We already own rotary coating equipment made in Takubo engineering, what are the precautions for using

A. What is the confirmation point of the existing line

- The existing line should have a drying oven that can be available for three coats and dry at 80°C for 20 to 30 minutes and 80°C for 5 minutes.

- Spray guns and paint pumps for the middle coat need to be dedicated.

Q. Can it be used in combination with an automatic mixing device?

A. Yes, it can. We will design an optimal system for you.

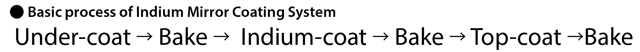

Q. What is included in the In. Mirror Coating System?

A. The basic configuration includes our coating robot (conveyor with rotating mechanism), spray gun, paint feeder syringe pump, dryer DRYTEC, oil booth, clean room, and teaching assistant software SWANIST (varies depending on design).

Other equipment includes dust eliminators, air showers (for workers and carts), and automatic transfer equipment.

- The choice of coating robots, such as Line Dancer or Swan Pro, is based on the required production volume, workpiece size, characteristics of the paint, etc.

- We will design and select the robot accordingly.

Q. How can we consider introducing the system?

A. As a rough guide, an in-depth hearing is conducted, coating tests are performed, design and confirmation are made, and a contract is signed.

- We will ask about the current coating situation, problems, etc.

- We will take your painted work and conduct a coating test. We will ask you to confirm the quality of the finished product, the coating time, and the paint usage fee.

- We will ask you about installation space, production volume, equipment requirements, etc., and start designing. Upon confirmation and approval, a contract will be signed.

- Please contact our sales representative for details.

Indium mirror coating system Catalog material download

The data is available for download.

![]() In. Mirror Coating System A4 8p(In-Mirror Coating System A4 catalog 8p-2Jboth.pdf:9MB)

In. Mirror Coating System A4 8p(In-Mirror Coating System A4 catalog 8p-2Jboth.pdf:9MB)