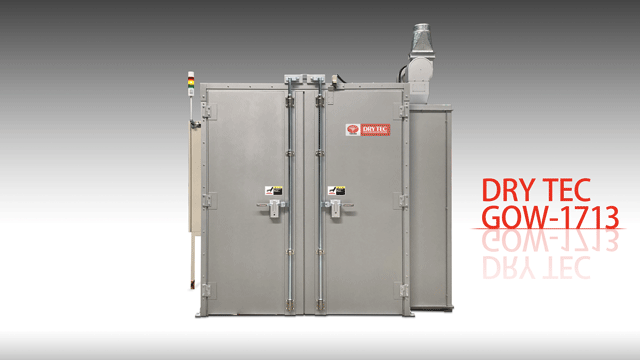

Dryer GOW-1713(DRY TEC)

Indirect heating system Exhaust heat recovery type Hot air dryer

This is a front and rear double-door hot-air dryer that improves productivity.

DRYTECH Front and rear double-door Medium Dryer

Dedicated coating dryer Front and rear double-door DRYTECH Drying furnace for batch production.

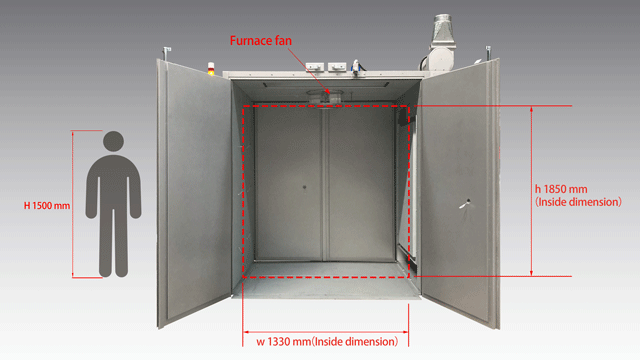

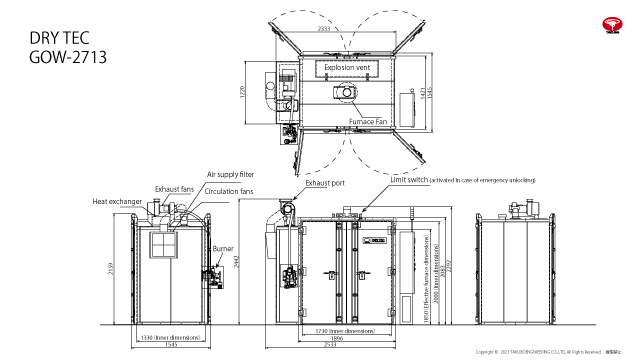

Size (effective size of furnace interior): w 1,730 mm x d 1,330 mm x h 1,850 mm, double-door type.

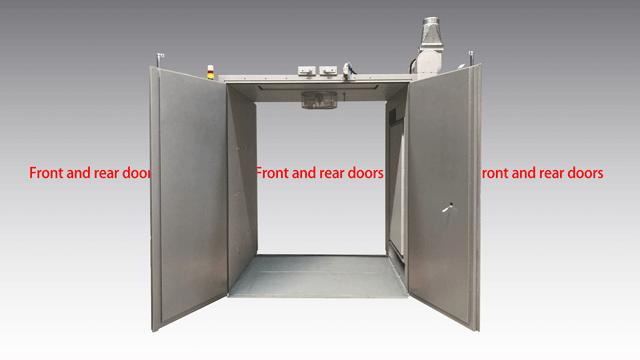

The coating room and the preparation room, entrance and exit, can be used separately. From the clean room (coating) to drying, and after baking, the workpieces can be taken out from the preparation room. This enhances work efficiency. This is a medium-sized dryer that can handle workpieces of various sizes, from small to medium and large.

Front and rear door specifications DRYTECH GOW-1713

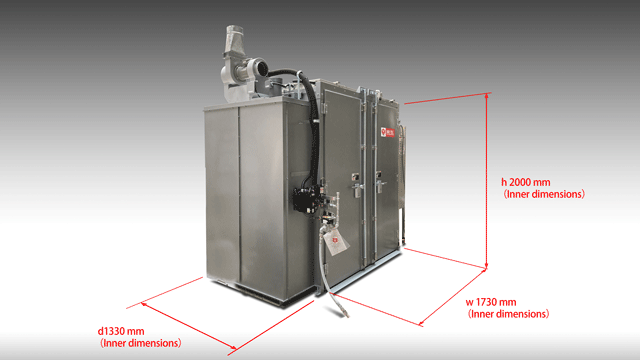

Furnace size

The effective dimensions of the furnace interior are 1,850 mm in height when the furnace fan is taken into account.

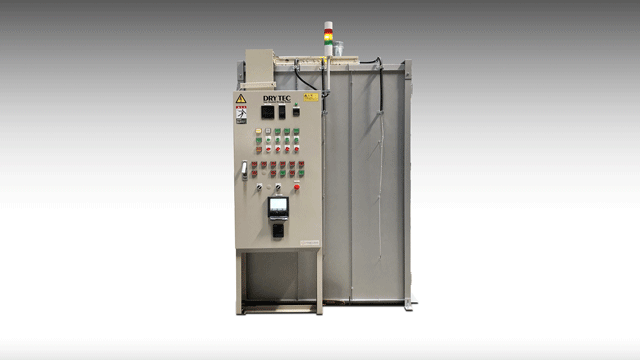

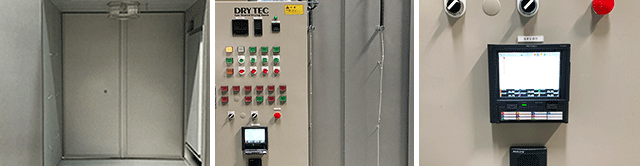

DRYTECH Equipment

Explosion Vent op

The explosion vent is a panel-type explosion protector that, in the event of an explosion in a dryer, opens an opening panel above the ceiling to the top to minimize damage to equipment and peripheral devices from the explosion.

It opens at the top when there is abnormal pressure in the furnace.

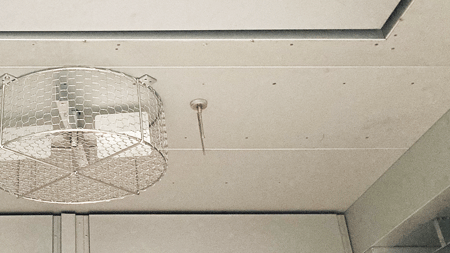

Temperature monitoring

Monitors the temperature inside the furnace.

The temperature recorder monitors the temperature distribution inside the furnace by installing sensors at the top, middle, and bottom positions on the side of the furnace, in addition to the sensors inside the furnace. The record is maintained.。

The records are stored on USB or forwarded via e-mail.

Monitoring device

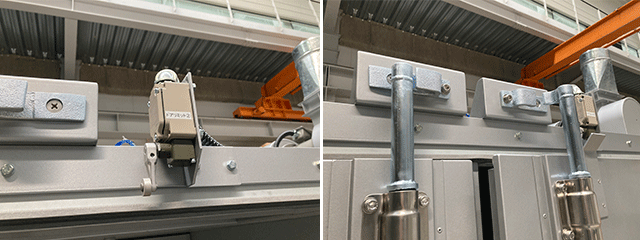

Monitors door opening during drying. If the door is found to be open, a safety device is triggered to stop the burner.

When the door limit switch is released (door open during drying)

1. Burner stops

2. Exhaust fan continues operation

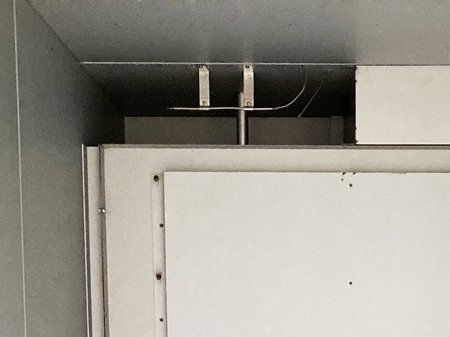

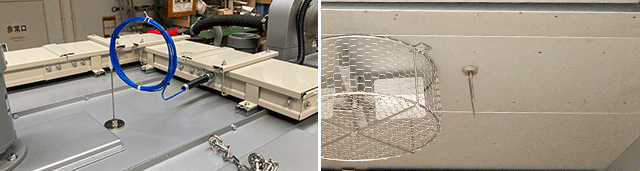

Emergency lock pick-up device

This equipment is used to open the door lock in the event that the furnace is locked during maintenance or cleaning. By pulling the wire, the container handle on the outside of the door unlocks and the door can be opened.

The container handle unlocks and the door opens.

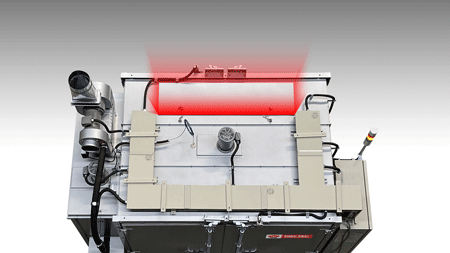

Furnace fan

The temperature inside the furnace is maintained at a constant level by rotating the fan. This averages the temperature distribution and prevents unevenness and other drying defects.

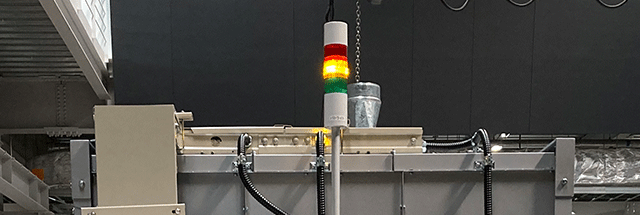

Operating status Display device

This is a patrol light with a buzzer. It signals the operational status of DRYTECH.

・Operating: Green

・Completed: Yellow

・Abnormal: Red

DRYTECH GOW-1713

DRYTECH GOW-1713 Outline drawing (Effective inner furnace dimensions)

| Dimensions | 1730 mm × H 1850 mm × D 1330 mm |

|---|

Options / Related Products

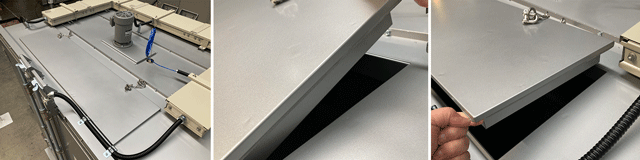

Explosion Vent

The explosion vent is a panel-type explosion protector that, in the event of an explosion in a dryer, opens an opening panel above the ceiling to the top to minimize damage to equipment and peripheral devices from the explosion.

When an explosion occurs, the explosion vent is immediately opened to its full extent by the pressure of the explosion, minimizing the destruction of the equipment.

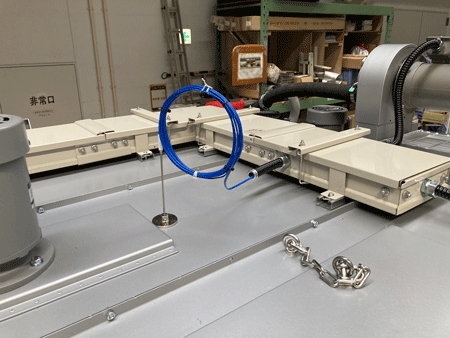

Escape Wire

In the unlikely event of being trapped inside the furnace, pulling the wire inside the furnace unlocks the latch handle and opens the door.

This is a safety evacuation device in case of accidental confinement during cleaning or maintenance.

Limit Switch

A monitoring device that shuts off combustion if the door is opened during drying (combustion).

Patlite

Notifies you of DRYTECH's status.

Furnace Temperature Sensor

Monitors the temperature inside the furnace.

Furnace temperature sensor & Recorder

Precautions

- Specifications are subject to change without notice. Please contact us for details.

- Copyright ©️ TAKUBOENGNIEERING CO.,LTD, All Rights Reserved.

- All rights reserved.

2023.03.31