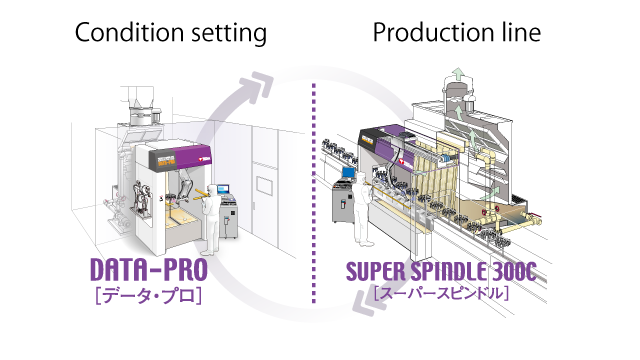

Role of the DATA-PRO(DATA-PRO)

Coating robot dedicated to coating data creation

To improve the efficiency of coating production

Producing coatings with high quality, low cost, and high efficiency begins with a review of the losses that lurk in the coating system. The prerequisite for starting conventional production is the condition creation process. This condition creation work is done on the production line, but by doing this work offline, unnecessary costs can be reduced and production can be done more efficiently.

DATA-PRO has many benefits for coating production

It eliminates a number of inefficiencies and waste in the coating production process. It also reduces the cost of coating, from the pursuit of coating to coating training and robotics personnel training, and has a wide range of other benefits for coating production.

Increase production efficiency with offline

Production line is not stopped

- No use of the production line for condition setting or sample preparation.

- Allows condition setting and sample preparation without stopping the production line and wasting energy.

- Reduce overall energy costs.

- During the coating production, the next model condition setting can be done.

Reduce coating cost

- No energy is wasted on drying, air conditioning, conveyance energy, etc.

- Eliminate unnecessary work.

- Reduce unnecessary paint consumption.

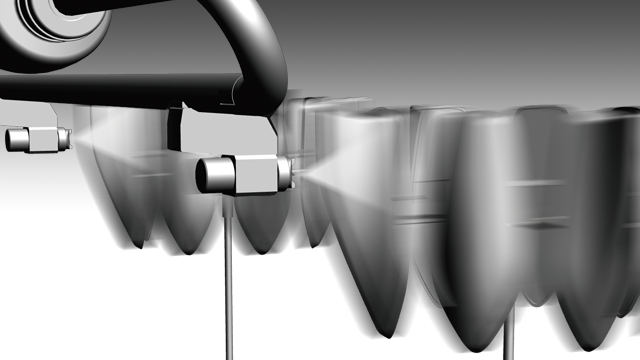

Pursue coating

Reduction of coating time

- Creation of teaching data to eliminate unnecessary robot movements

- Condition setting to eliminate paint loss

- Management of coating data by workpiece

Reduction of wasteful paint usage

- Reduce the amount of paint used for condition setting, such as in preparation paint, test paint, etc.

- Calculate the amount of paint used in production to reduce wasteful paint usage

- The "one-cup system," a paint feeder that can control paint in 1 cc increments, controls paint delivery and reduces wasteful paint use.

Pursuit of film thickness and quality

- Control of coated materials

- Pursuit of ultra-thin films with severe film thickness, such as plating-like coatings

- Pursuit and study of paint films

Improve the level of technology

Training of robotics personnel

- Training of coating robot personnel, including color change, maintenance, teaching, and conditioning.

- Jig development and its education

- Efficient robot movement, teaching education, and training

Pursuit of design coatings

- Pearl, metallic, and new coating development

- Creation and condition setting of coating plate samples for a wide variety.

Pursuit of functional coating films

Coating film performance evaluation

Enables distributed production

Standardize the quality of the scattered factories

- Stabilization of quality by transferring coating data

- Advanced reproduction performance allows for easy adjustment and playback

- Coating data such as condition settings including teaching, workpiece information, and robot position information can be transferred by e-mail or storage media.

- Easy installation to robots on the production line via e-mail or storage media such as USB

Avoidance of distributed production risk

- Eliminate factory-to-factory quality variation

- Reduce variation in coating costs between factories

- Bases for condition setting work

- Reduce operator work

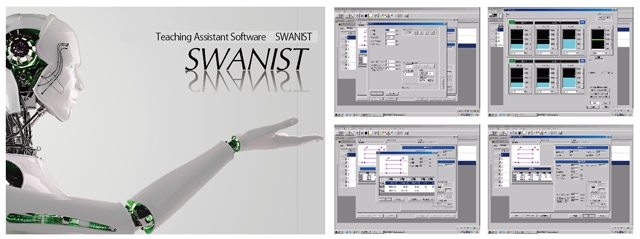

Easy operation with SWANIST

Teaching Assistant Software SWANIST

- Eliminating the reliance on sensory input to set conditions, and digitizing all work by entering numerical values

- Reproduce expressive coatings with simple training

- Coatings with high repeatability and good mass-production performance are realized

Improved environmental performance

Sludge and VOC emission control, etc.

Reducing wasteful paint use, the Boss 2000 paint sludge collector, connected to an oil booth, solidifies paint sludge through centrifugal separation. Reduces the amount of paint sludge to be disposed of. The oil booth has a low-noise design of 63db. It is far quieter than no-pump booths and other water rinsing booths, greatly improving the work environment and making the coating facility more friendly to workers and the local environment. By reducing unnecessary use of paint, VOC emissions can be reduced.

Need for Data Pro

To reduce coating costs and achieve high quality coatings efficiently, an offline coating machine is essential. Digitally connected robots are linked by coating data to enable the production of the same quality and at the same coating cost in each location and at each factory. Coating production is achieved when robot technology, paint supply systems, coating technology "R technology," dryers, booths, and equipment necessary for coating share the idea of the coating path. Super coatings that become a commodity are achieved.