Machines for Batch/Cell Production(Manual method)

Coating robot collaborates with human workers, the most suitable for small-volume and multi-kind production

This is a high-efficiency robot which realizes collaboration with human workers so that the robot makes coating while human workers are preparing work components to coat. Our robot line-up includes SWAN robot with high-accuracy, TAKUBO’s original W-turn, Super-spindle M-type W-turn-type robot, and Station type robot which has a separate coating station.

Lineup

-

SWANCoating Robot

A single robot

Independent type robot and W-Turn, both Takubo original, are combined. This is a compact coating robot system dedicated for R-Technology of Revolving Coating.

-

SWAN-application

A single robot

SWAN is suitable for any kind of coating systems in a wide range, from manual to automatic methods. It is a coating robot to manage all coating system including coating trial, multi-kind and small-volume production and mass-production.

-

Double-Turn Type

For Robotic Unit

This compact model is designed for automated applications. One is used in a set with a linked handling robot for each dolly, allowing per-dolly automated operation. It can be integrated into a fully automated line in future.

-

Single-unit

A single robot

From Batch-type with a worker or semi-automatic system to automation-type with a handling robot is the wide territory for this robot system. It is suitable for the small-volume and lots of kind production.

What are robots suitable for Batch/Cell Production?

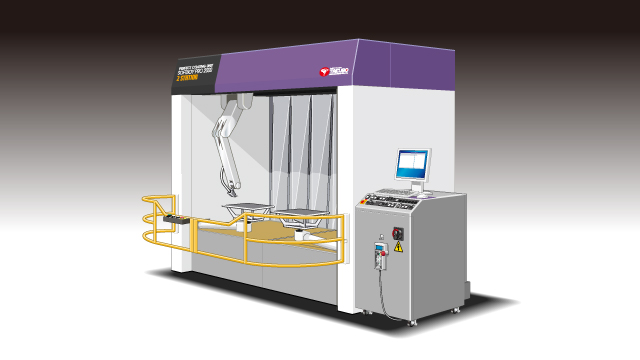

Production method in which human workers are involved, SOFTBOY PRO series

Robot suitable for Batch/Cell production means the robot suitable for collaboration production style with human workers and robot so that human workers set up work components with jigs and the robot coats them That is, the robot series are suitable for the coating productions which have so many color and set-up change with multi-kind and small-quantity production There are SOFTBOY PRO W-turn series, Station series and SWAN series. Especially regarding the newly developed SWAN series, it is very easy to install. Furthermore, it has One-cup system, coating material supply system, as a standard equipment. You will be able to start using it for actual production soon just after setting it in front of the existing booth and easy tubing wok.

SWAN series

- SWAN-1600 type: Standard machine

- SWAN-1200 type: Optional machine

- SWAN-1400 type 2T: Optional machine

W-turn type

- SOFTBOY PRO W-turn type (using S-type robot arm)

- LINE DANCER W-turn type (using M-type robot arm)

Station type

- SOFTBOY PRO 2 Station type

- LINE DANCER 2 Station type

Coating Robots suitable for Batch process and Cell production

SWAN series

This is an explosion-proof robot with the pearl paint and round body, which is never seen before in usual coating robots. SWAN is an independence-type coating robot in which our original W-turn with high-accuracy. The new type coating robot is following the revolving coating R-technology so that it coats 2 jigs at the same time reasonably by revolving coating.

- It is possible to choose SWAN 1600 or 1200 depending on the work size (Left and Mid. on CG). Rotation diameter of W-turn will change.

- 1400-2T is the most suitable for heavy work component such as an automotive wheel. The number of revolving table is just 2.

SOFTBOY PRO W-turn type

This is a world-new ceiling-suspended type robot. Robot is designed in a coating booth so that it is very safe and compact. You can see the actual state of coating, and also both revolving and net coatings are manageable as you like.

Station type

SOFTBOY PRO Station type, Suitable for Color creation, Sample manufacturing and Small-volume production This coating robot is so convenient in collaboration production that one work-station takes robotic coating and the other one has touch-up or air-blow work. It is suitable especially for small-volume production.

Options / Related Products

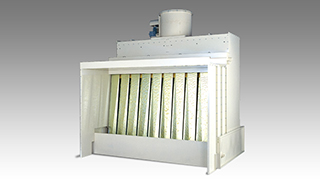

Oil BoothLink to product page

Oil Booth is a Coating booth with long life and low noise design in using oil as cleaning liquid. (OIL BOOTH is a registered trade mark of Takubo Engineering Co., Ltd.)

DRY TEC, Drying oven dedicated to coatingLink to product page

DRY TEC is Takubo’s original heat-recovery gas hot-air drying system in which excellent economic efficiency, safety and coating performance are realized. (DRY TEC is a registered trade mark of Takubo Engineering Co., Ltd.)

更新日:2016年9月3日