Teaching assist

Teaching Assist for Coating Robot

Originally developed dedicated Teaching Software for Coating Robot

One of the most important operation in a robotic coating production is a teaching work to teach the motion to the robot. Essentially robot has its own dedicated robot language, and the teaching work is executed by the dedicated teaching software. While the common software is used for teaching work in welding or handling robots, our original teaching software developed dedicatedly for coating work is used in TAKUBO ENGINEERING’s SOFTBOY PRO series robots. This original software is developed exclusively for coating robots so that the necessary spray condition setting, the spindle control for R-Technology, and ON OFF or switching function of paint are merged in the software.

Lineup

-

KEITAI PACKTeaching software for Smart phone and Mobile phone

Revolving coating work for mobile phones and smart phones becomes so easy by【KEITAI PACK】

Mission imposed on coating robot. Developed to challenge the cost.

All functions to reduce the cost is in the software.

Studying a number of useless unknown waste, and also considering coating technology, safety, economical matters, yield and so on, from the all aspects, we have been developing both teaching software and ideal equipment.

We will solve a lot of problems about useless waste hidden in coating.

- Wasted paint consumption

- Waste of solvent used in cleaning

- Waste of line stop occurred in color change

- Useless time in coating

- Useless defect of coating performance

- Too many robot axes

- Individual purchase of equipment necessary for coating

Pursuit of revolving coating technology 【Revolving coating, R-Technology】

Work components are controlled to turn in both CW and CCW so that the multi-layer and thin-film coating performance can be produced, in which very thin films are coated many times. This multi-layer and thin-film coating method improves coating quality and also maximize the functionality of paint so that wasted paint consumption is reduced.

Development of the equipment to reduce paint consumption

Paint supply volume is precisely controlled by 1cc in order to reduce useless paint consumption by our original paint supply equipment. Also consumption volume of cleaning solvent in color change and so on is reduced very much.

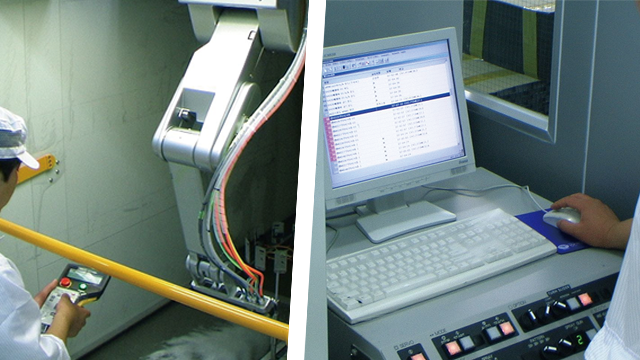

High grade equipment cooperative control

It is possible to directly set teaching work and condition setting according to work component and paint so that workability and productivity are improved.

High grade equipment cooperative control

It is possible to directly set teaching work and condition setting according to work component and paint so that workability and productivity are improved.

Development of explosion-proof device

Development of small-size explosion-proof motor can achieve both safety and cost.

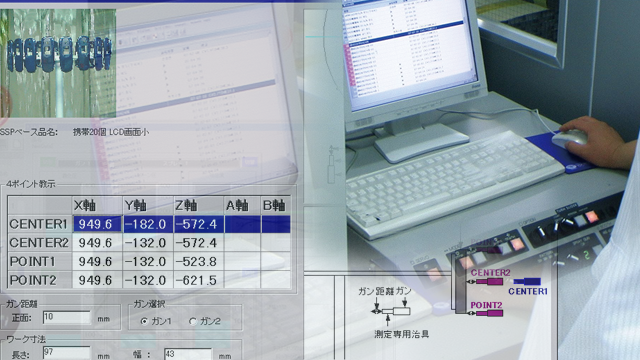

No need to input robot language

Omitting the work for robot, concentrating on pursuit of coating work.

Teaching is operated by PTP on PC without any input of robot language.

- Easy to make data copy and paste

- Easy data management because of operation on the original software

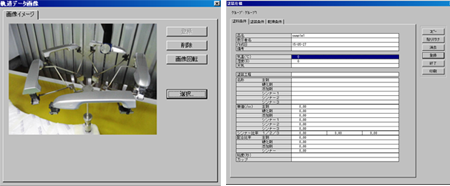

- Registration work component picture. Coating conditions are saved and managed with their images.

- One group is able to have 500 data, and 21 groups are available.

- Data capacity: 4GB flash media is included as standard accessory.

To manage every kind of work component by revolving coating

Other support software

【KEITAI PACK】

Teaching software, in which the teaching for the height of turning work components is (Y coordinate) is automated, is good for circle-ring jig with multiple work components such as mobile phone or smart phone or other similar shape ones.

【DISC PACK】

Easy teaching software for revolving coating with horizontal placement of work components on circle jig

公開日:2017年3月24日