GOW-253040(DRY TEC)

xample of installation of Passing-type drying machine, DRY TEC Special order GOW-253040

Trolley line compatible. Passing-type DRY TEC

Designing a trolley line inside DRY TEC. Customizing DRY TEC front and back door type to use it as a line drying oven.

Custom-made product example GOW-253040 Trolley line compatible

- Heat-Recovery type Hot Air-Drying Device, DRY TEC, can be customized in a variety of scenes, from Batch-type to Passing-type. Because of the panel structure, you can enjoy extensibility and flexibility.

- DRY TEC is a drying device with high speed of start-up, good temperature distribution in the oven so that high fuel efficiency and excellent coating cost-performance can be realized.

- DRY TEC has been successfully used also as Camel-back drying oven for a long time. The batch type drying oven can be equipped with trolley line on top of the oven as line type.

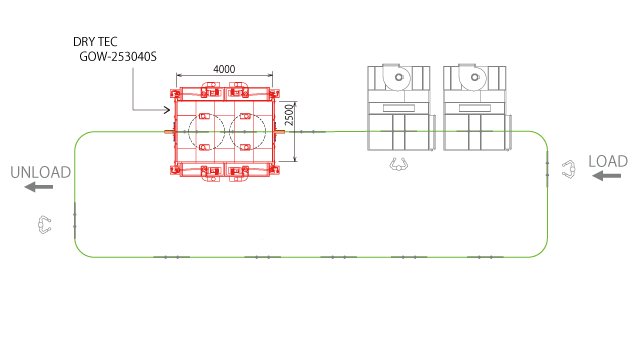

Installation Example of DRY TEC Passing-type

Trolley line

Trolley line in DRY TEC furnace. Manually operated.

Pass the popular trolley line inside DRY TEC.

DRY TEC Passing-type

Trolley line passing type (Manual)

Installing the trolley line in the DRY TEC oven. Manually loading the work components in the oven.

Trolley line

Trolley line (manual type)

Trolley line in DRY TEC furnace. Manually operated.

Circulation fan

4 internal circulation fans installed

Average the temperature distribution in the oven.

Hot air generator

Heat generation 48,000 kcal x 4

Four Hot Air Generators with each 48,000kcal/h/unit are installed. Temperature rise time is 40 to 50 min / 150 ° C. Hot air heated from the bottom is blown and circulated in the oven.

Intake filter

Intake Filter

Intake filter removes dust to provide purified air to heat exchanger so the oven receives controlled pure heat energy.

Temperature control

Oven temperature control and monitoring

The oven temperature is controlled and monitored by the controller for keeping the oven temperature constant and the over-heat monitoring controller for monitoring burner abnormalities.

Drawing and layout

Layout

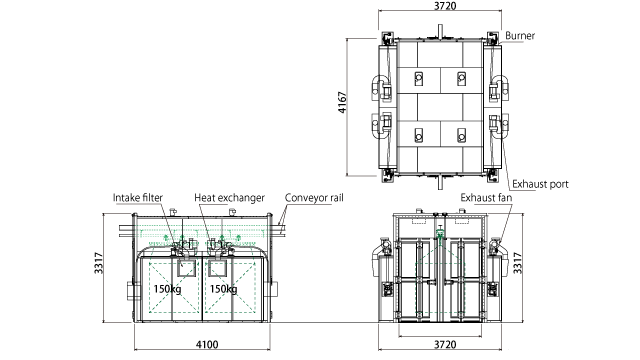

Specification drawing

Specifications

| Burner | 14-type High/Low Temp, 2 unites | |

|---|---|---|

| Heat Exchanger | 4mm 4units | |

| Circulation Fan | 0.4kW 4units | |

| Intake/Exhaust Fan | 0.25 kW 4units | |

| Fan in the oven | 0.4kW 4units | |

| Calorific Value | 48,000 kcal/h4 | |

| Fuel | LPG 24,000 kcal/m3 | |

| Power Voltage | 3∅ AC200V 50/60Hz 4.2 kW | |

| Internal Dimensions | W: 2,500mm x H 3,000mm x D 4,000mm | |

| Internal/External Plates | SPC 0. 8t (Baked coating for External Plate Metallic Silver) |

|

| Temp range | 80〜200℃ | |

| Time of temp rising | 40〜50 min/150℃ | |

| Temp Control Method | ON-OFF method (Sensor: K-type heat terminal) |

|

| Safety Device | Flame Monitor, Over-heat Protection Device, Air-flow Switch, | Over-heat Protection Device for Burner, Over-load protection for Motor |