Coating Method/System in general

Q&A regarding Coating System

Q. Is it possible to design a pre-treatment facility such as degreasing in the coating system?

A. It is common to separate a coating line and a pre-treatment facility such as degreasing because industrial medicine might have an adverse effect on coating production.

Q. Is there any bad quality influence in case of the production with multi-coating in one booth?

A. Although it depends on the design of the booth, there is be no bad influence. In our achievements, we do not have any report to have an adverse effect.

Q. What is the coating system to make 2 to 4 coatings by only one robot?

A. This is a system to make coating production by only one robot with four guns in working with a handling robot. For example, "1R2C" is a robot to make 2-coat operation. So, "1R3C" is for 3-coat, and "1R4C" is for 4-coat. Working with a handling robot means wet-on-wet coating production by transferring the work components to a conveyor zone for setting (flushing).

Q. How much volume is the thinner consumption during color change?

A. Although it changes depending on the color change/cleaning method, the consumption volume is approximately from 500cc to 1,000cc.

Q. Is there any method to quickly make color change?

A. There are two methods, one is Switching method to change the spray gun, and the other is Color Change Valve System to use the valve.

Q. Is it possible to make color change for multiple spray guns at the same time?

A. Yes, it is possible. On the system, color change can be executed up to 8 guns at the same time.

Q. How long does it take for color change?

A. Although it changes depending on the model, it takes approximately from 30seconds to 3minutes until completion.

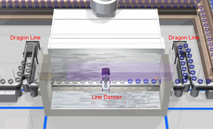

Q. What is difference between Super-spindle 300C and Dragon line?

A. In the coating robot system of Super Spindle 300C, the robot can follow the running conveyor, on the other hand, the conveyor line can stop during coating by accumulation mechanism in the conveyor line of DRAGON LINE. DRAGON LINE can make the booth smaller to reduce the energy cost even in case of the line operation with multiple (for example, more than 6) guns.

Q. What is the criterion to determine how many guns to use?

A. In order to manage a large production volume requirement, we are not increasing the number of robot but the number of spray gun to load on a robot. The maximum loadable weight of the robot arm of SOFTBOY PRO series is 20kg so that it can load many spray guns and coat many work jigs at the same time.

Q. How long does it take from PO to Hand over?

A. Although it changes depending on the system contents, it takes about 3 to 4 months from PO to Handover.

Q. Is it possible to visit any coating system or ask for a coating test in China?

A. Yes. It is possible to visit our coating systems or to make a coating test in China. We are arranging environment for demonstration.

Q&A about Coating Method

Q. What is the coating system to decrease the total energy?

A. The total energy means all of the energy for coating robot, drying machine, air-conditioning, paint consumption, air consumption, air-supply/exhaust(including motor), lighting, cleanroom and so on. We mean the coating system which can reduce such energy for coating production. We, TAKUBO ENGINEERING, are developing and manufacturing our own products and total system from designing originally in order to reduce the total energy.

General Q&A

Q. Does TAKUBO have any service center in China or Taiwan?

A. Now we are planning to set such service gradually to make after-care service in Asian area.

Q. Is it possible to install or sell the coating system in the western region?

A. Our products do not take certification such as CE(Communaté Européenne)in Europe. That is, it is not possible to export the products (explosion-proof motor) without CE mark to EU Member States (they reject to import). Therefore, we do not accept any sales in Europe. If the demand increases there, however, we will study to take such certificate from now on. In case of export to countries other than EU Member States, we have no problem to sell and install our products. Please do not hesitate to consult with us.

Release date: July 4, 2017