Machines for Line Production(Automatic method)

Coating Robot

Coating robot with high production efficiency

In the coating robot series for conveyor, there is a mass-production type coating robot with maximum 12 spray guns by mainly using LINE ANCER M-type robot with the loadable weight of 20kg. SWAN S-type is also a reasonable and mass-production type coating robot. It has maximum 4 guns and is able to manage Continuous following and Tact line operation. In case of mass-production coating for small-size work components, Super Spindle 300C is the most suitable coating robot.

Lineup

-

LINE DANCERLINE DANCER

The world biggest class coating robot with max 12 guns mounted on one robot arm, and the most suitable coating system for smart phone cases or covers

-

SUPER SPINDLE 300C

SOFTBOY PRO SUPER SPINDLE is a coating robot system developed specifically for work pieces such as mobile phone handsets and mobile communications devices. It is a completely new type of coating system that keeps energy costs down and is highly expandable.

-

SWAN-SCoating robot

SWAN-S is a type of SWAN robot without W-turn of handling device. Setting multiple set of SWAN-S on the line will make a continuous mass-production operation.

-

Coating Robot System for Outside MirrorsLINE DANCER

Necessary technical factors are taken into the robot and the system.

What are robots suitable for Line Production?

Divided into two main groups, Following type and W-turn type, in SOFTBOY PRO series

Robot for Line production mean a coating robot to be built on line so that the robot coats in following the moving conveyor at the same speed. This coating robot has the most efficient productivity in SOFTBOY PRO series. Setting a robot in DRAGON LINE which has accumulation mechanism on conveyor line, the robot coating system with low running cost due to a shorter booth is also available because the conveyor line can stop only in coating by the robot. There are two main groups in the SOFBOY PRO series, which are the Following type and the W-turn type. Handling equipment is connecting between the conveyor line and the coating robot in the W-turn type. We will propose the most suitable and the lowest running cost type system to you depending on your production volume or coating (color change) numbers.

Types for Line Production

- SUPER SPINDLE 300C (using S-type robot arm, loadable of 2 to 4 guns)

- LINE DANCER (using M-type robot arm, maximum loadable weight of 20kg, loadable of 2 to 12 guns)

W-turn type, line and coating robot are separated

- LINE DANCER W-turn type with 2-top (using M-type robot arm, maximum loadable weight of 20kg)

- LINE DANCER W-turn type with 4-top (using M-type robot arm, maximum loadable weight of 20kg)

- LINE DANCER W-turn type with 6-top (using M-type robot arm, maximum loadable weight of 20kg)

Coating Robots for Line Production

SOFTBOY PRO SUPER SPINDLE 300C

SUPER SPINDLE 300C

- SOFTBOY PRO SUPER SPINDLE 300C using S-type robot arm

- Coating robot loading 4 spray guns (CG) to be able to set on the line

SOFTBOY PRO LINE DANCER

LINE DANCER

- LINE DANCER M-type robot with the maximum loadable weight of 20kg to set on the line

- Simultaneously coating 6 ring-jigs by 6 spray guns (CG)

- Combination with DRAGON LINE will make the coating booth smaller and also reduce the energy cost.

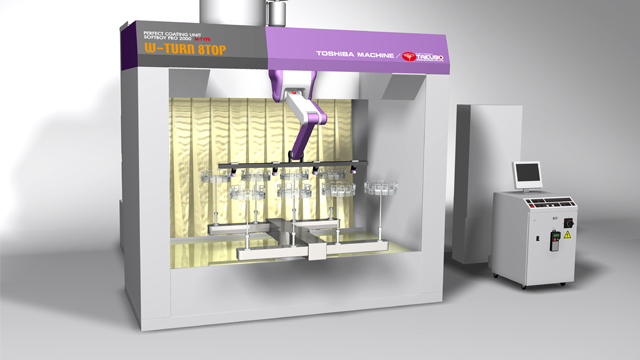

SOFTBOY PRO LINE DANCER W-turn type

LINE DANCER W-turn type

- LINE DANCER W-turn type using M-type robot arm

- Simultaneously coating 4 ring-jigs loading 4 spray guns by the revolving coating

- Total 4 rotation tables, front, back, Coating 4 tables, for coating

Options / Related Products

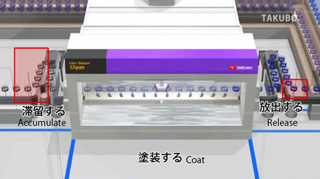

DRAGON LINELink to product page

DRAGON LINE, the most efficient conveyor line, which is dedicated to robotic coating, has the feature that work components on the conveyor line stop only during their coating. This efficient revolving coating will increase the productivity and reduce the energy consumption.

Peripheral equipment Link to product page

Stable paint supply is necessary for improvement of coating quality. TAKUBO ENGINEERING has been developing many products to contribute to the better coating quality and environment such as our original Syringe Pump, new idea Hose-less supply system and others. Also regarding drying device, we have been making our original development, for example, our standard DRY TEC or the latest JOU-LO system.

公開日:2016年8月30日