R-technology Vol.1

Dr.TAKUBO's COLUMN

Birth Background of R-technology

R-technology is a robotic coating technology to deliver multilayer thin-film coating performance having works spin and also having a robot follow them in combination with a conveyer.

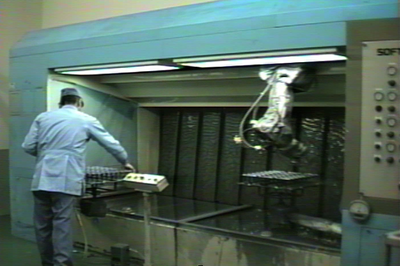

We developed this revolving coating technology, R-technology, in 1996 when mobile phones were just introduced. It was three years before “i-mode” appeared in 1999. At that time the major method for robotic coating was Net Coating in which work pieces were laid on a 600mm square net and the robot simply repeated moving horizontally above the work table which turned by 90 degrees each time. It was an imitation form of coating by person, that is, “Spray Man” method.

Net Coating Robot SOFTBOY in 1990

The times suddenly advanced, and the customer needs also became higher.

High Quality: Fixed Film Thickness, High Brightness, Defect by Dust, Lower Cost, Mass Production and others, the customer needs became higher and higher. Accordingly we had to develop quickly.

When our staff members of Technology Development Division watched some drawing outputs from the plotter one day, they found that the plotter drew figures, shapes and letters in its original moving way, which was incomprehensive to the eyes of human beings. That is, they understood that there was a suitable and rational movement for a machine and in other words the most robotic movement for a robot. They stopped the thought to pursue the Spray Man’s movement to develop a coating robot, and then started developing a new coating with robotic movement, in which a robot could move flexibly, instead.

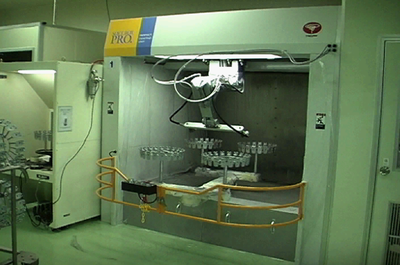

They developed a new technology and methods to mount some work pieces on the circumference of a circle jig and to make the robot coat the works while rotating the jig itself. That was a beginning of the R-technology.

This new technology achieved enough effects such as the most suitable thin film layers for mobile phone and the quality stability. On the other hand, the problems which were hidden before appeared one after another. They were importance of jig, material supply pump, booth, and peripheral devices such as air conditioning. It was in 1996.

Super Spindle SOFTBOY PRO in 1997

Next “R-technology Vol.2” is about the importance of jig in a robot coating system.