R-technology Vol.2

Dr.TAKUBO's COLUMN

Importance of Jig

R-technology is a basically revolving coating, in which work piece is revolved during coating.

The major difference from the conventional spindle coating is a design of the jig.

What we call the revolving coating now is a revolving coating method for ceiling-suspended moving-type coating robot of SOFTBOY PRO. It is totally different from the methods of a usual fixed gun or a balance-arm type robot.

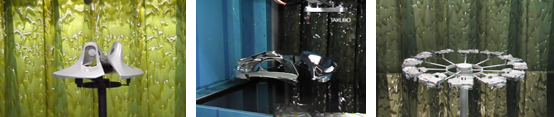

In the revolving coating of SOFTBOY PRO, the robot arm can coat with no waste and the minimum movement. In other words, the robot can coat easily by little movement. In order to arrange such movement, making the best position including an angle for the robot against the work piece is necessary when you set mounting multiple work pieces on a revolving (circle) jig. This is the jig design.

Work piece should be at the position where SOFTBOY PRO can coat easily. This is the purpose of the jig design. The structure just to mount work pieces on a circle jig is not enough. The jig design should include some important points as follows.

◎When work pieces are revolving, the robot has no useless motion (shortening the coating

◎When work pieces are revolving, the difficult parts such as uneven should be at the easy position to spray them (eliminating sagging, lack of hiding and uneven coating).

◎It is easy to remove and mount work pieces (shortening the preparation time / efficient operation).

◎It should be compact (preventing drying oven from becoming uselessly large).

◎Dusts hardly adhere on it (preventing inferior products).

◎It should support making the required coating-film performance (in case of super-luster or piano touch etc) Takubo-TVe (YouTube)

Takubo-TVe (YouTube)

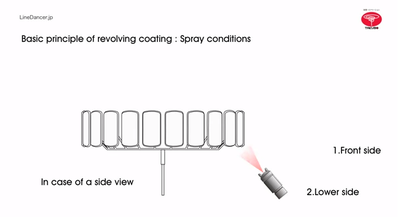

▶ Spray conditions

These are the necessary conditions to reduce the cost and also to make a mass-production with high quality coating.

Using R-technology of SOFTBOY PRO, we are providing our customers with a proposal about some improvement of the jig (mask jig) in accordance with the kind of work.

For example, we asked our customer to make a special pallet which looked like a donut divided by four. We proposed them to make a revolving coating with the special jig instead of a conventional square pallet just on which buttons of works put. In result, the paint consumption volume was reduced so that the advantage of the revolving coating was clearly confirmed.

The work pieces were the buttons for inner illumination, in which film thickness should have been strictly controlled, and letter-finish was made by laser cutting.

Trial or challenge with free imagination, ignoring the conventional limit, will generate unexpected effects.

The next, R-technology Vol.3, is Setting of Coating Conditions by SOFTBOY PRO.