R-Technology Vol.3 Condition setting

Dr.TAKUBO's COLUMN

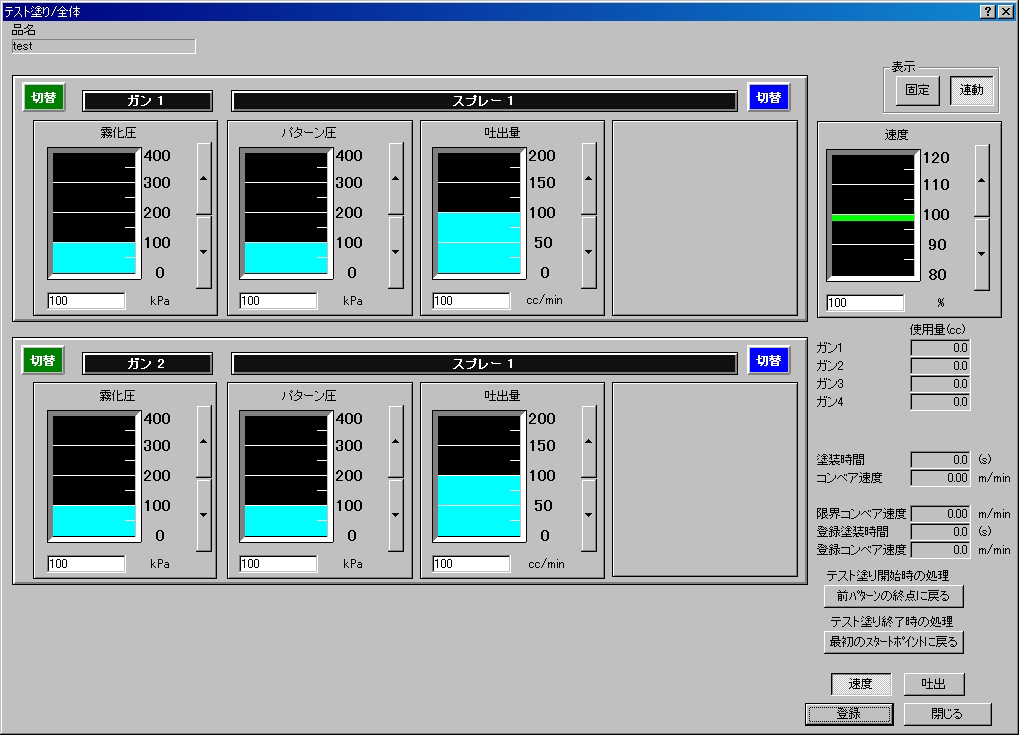

Condition setting of coating

What is condition setting in the coating robot?

・Control of paint from spray gun (Numerical control of discharge, atomization and pattern)

・Robot motion teaching

The above are the main condition settings. They are important items in robot coating and have a great influence on quality and coating cost.

Realization of "R-technology" that meets the requirement of condition setting by connecting the control of auxiliary equipment such as paint supply device (Pump), revolving device, and transfer device to realize even finer condition setting with highly integrated technology doing.

"R-technology" simplifies this basic condition setting and makes the software easy to handle. The purpose is to complete robot coating by digitizing what was originally conditioned by feeling and memory of hand-spray painting, and inputting it numerically in an easy-to-understand interface. However, since there was no coating robot that can skillfully set conditions, TAKUBO ENGINEERING developed its own dedicated robot and completed it as a coating robot system.

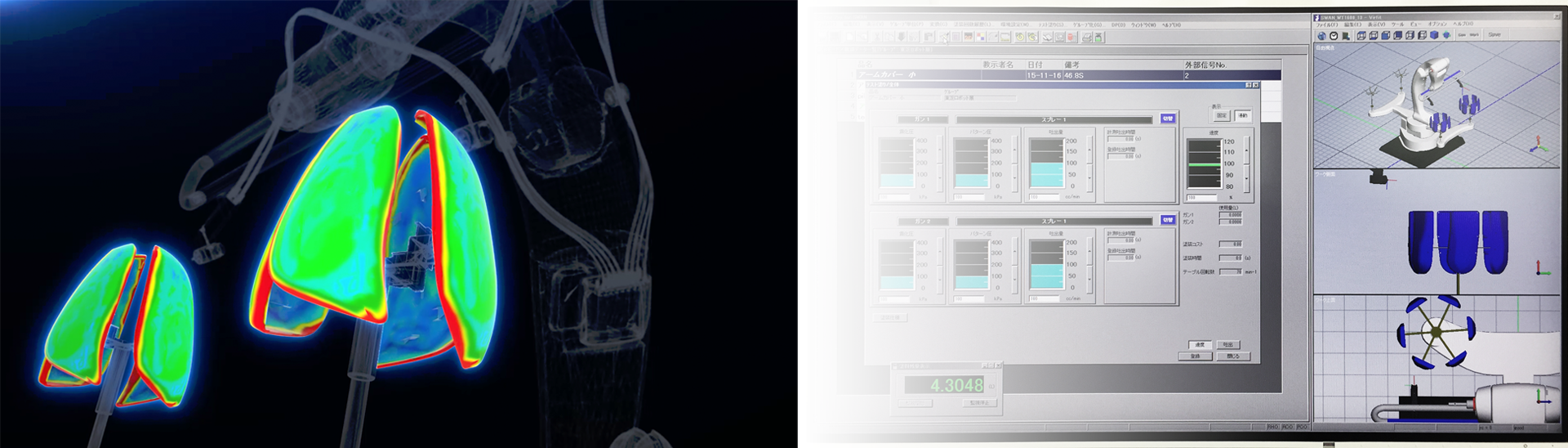

Overriding the theory of a 6-axis robot that it is a wonderful robot if the robot has many axes, the "R-technology" was realized by devising a coating technology based on a movements suitable for machines. TAKUBO's coating method is a thin film multiple coating method in which the workpieces are rotated and the spray gun waits for coating. The mechanism control to rotate the workpieces is installed in the robot, and the robot is taught by the simplified teaching software, and at the same time, the spray condition setting is input. This is an extremely natural mechanism developed to realize high-quality, large-scale coating production.

As a result, "R-technology" has many positive effects. For example, reduction of wasteful paint usage fees, optimization, improvement of quality, realization of highly functional coating film by film thickness control, and significant reduction of industrial waste cost.

Importance of condition setting

Clearly, mastering this condition setting is essential for improving defect rate and yield.

At TAKUBO ENGINEERING, we have introduced fluid analysis technology and are developing teaching assistant software "SWANIST" so that the results of painting can be known in advance in a virtual space.