Note PC SSP300C

Coating System exclusively for Note PC

Automated Revolving Coating for Note PC parts SUPER SPINDLE 300C

Coating system exclusively for Note PC parts such as Mg metallic parts, Monitor frames made of resin and so on, so that high-grade production with low paint consumption and stable thin-film can be realized by our revolving coating technology, R-technology.

Features

High-grade Coating can be realized by detailed Gun-condition setting

Possible to set spray-condition for each part

It is possible to make condition setting in details for each part such as stub-up points, hollows and flat parts. High-grade condition setting by Revolving Coating generates an excellent performance without sagging, lack of hiding, or uneven coating.

Managing any materials from Mg metal to Resins

Revolving technology, R-technology, can manage every kind of materials.

It is possible to make detailed condition setting in the SOFTBOY PRO. In case of material change or paint change, easy adjustment of spray-conditions can manage such situations quickly.

Realizing revolving coating with the original teaching software

R-technology

One of the most difficult problems in a usual revolving coating is to make a stable thin-film between periphery and center of the work. SOFTBOY PRO installed with our revolving coating of R-technology can easily make such adjustment by the original PACK teaching software. Exquisite balance among spray condition, revolving speed, and robot movement drawing a corn can realize a great film performance without any difference between periphery and center of the Note PC.

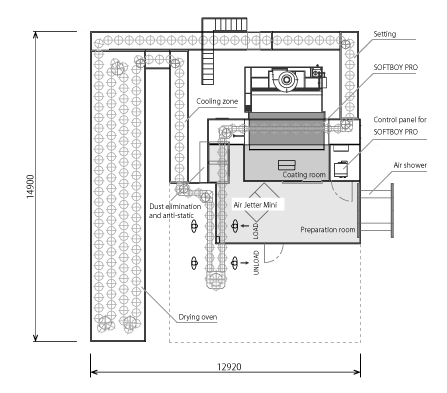

System for measure to prevent dust inferiority

Dust-elimination and anti-static device is on the operation line.

Air Jeter Auto, dust-elimination and anti-static device, is laid out before the coating robot on the operation line. Automatic dust-elimination and anti-static device prevents dust inferiority. There is Air Jeter Mini to be set as option. The dust-elimination booth to use in a clean room helps air blowing for work pieces before coating.

Clean room with class 100,000

System to control both temperature and humidity always keeps a stable surrounding in the coating room. In addition to the temperature control, surrounding measures against dust-invasion, static electricity and others are installed considering any bad influences on the coating film.

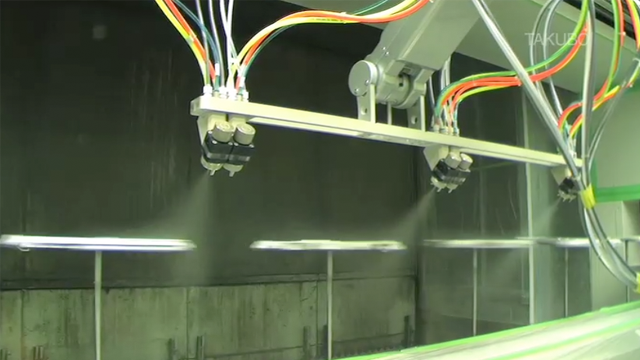

Mass-production efficiency by multiple guns

Mounting multiple guns on a robot

The most important feature of SOFTBOY PRO is a Ceiling-Suspended Moving Type. In order to utilize the feature, multiple gun mounting is necessary. Our original developed multi-gun attachment, “PRO POWER JOINT”, increases production volume per one robot effectively. You can get higher productivity of one robot without any large facility space and also increase mass-production efficiency.

Multiple-gun is designed in advance according to the target production volume.

The number of gun for mounting is customized according to the production volume. Production volume per one robot is effectively maximized.

Adopting a super precise certain-volume supply equipment, Syringe Pump System

Precise certain-volume supply by 1cc unit

- Takubo’s original coating material supply system only for coating, Syringe Pump System, can control material volume by 1 cc unit. It can decrease the waste material consumption and also save the cost.

Syringe Pump System for 3 guns (2×3) - It is very simple in design of the structure. Cleaning and maintenance are very easy so that consumption of the cleaning solvents can be reduced.

- Of course, color change is also easy. It is possible to manage program change or model change spending a much shorter time.

No dispersion for each gun creates the high grade production with multi-layer thin-film coating.

There is no dispersion for each gun because we set one cylinder for one gun to make a stable volume control in the Syringe Pump System. Therefore, high grade production can be realized in coating multiple work pieces simultaneously.

Automatic coating system, SUPER SPINDLE 300C

Using SOFTBOY PRO S-type as robot

S-type SOFTBOY PRO is used in this coating system for Note PC. SUPER SPINDLE 300C, automatic coating synchronized with conveyer line, is basically designed. Automatic coating system for Note PC can manage 2-coating operation.

Reference Layout

Basic Specifications Example

| Work name | Note PC | |

|---|---|---|

| Cycle time | 45sec | |

| Processing Units | 3jigs | |

| Setting Time | RT 3min | |

| Drying Time | 30 min75~80℃ | passing time |

| Dimensions for Work-Jig Mountings | φ400 |

Capability

| Production volume | 1,920pcs | /8h |

|---|

Options / Related Products

SUPER SPINDLE 300CLink to product page

Syringe Pump SystemLink to product page

Clean roomLink to product page

Air Jeter MiniLink to product page

Movable, Compact Dust-Elimination Booth High-performance filter is internally set to make dust-elimination circulating the air. No need of exhaust duct allows use in a clean room.