SUPER SPINDLE 300C

Mass Production Type Coating Robot

The spindle coating system is the now dominant type for mass production applications.

However, this type of system has many problems, including poor coating efficiency, high coating material consumption volume, extensive equipment requirements, poor operational efficiency, and high overall energy costs.

SOFTBOY PRO SUPER SPINDLE is a coating robot system developed specifically for work pieces such as mobile phone handsets and mobile communications devices. It is a completely new type of coating system that keeps energy costs down and is highly expandable.

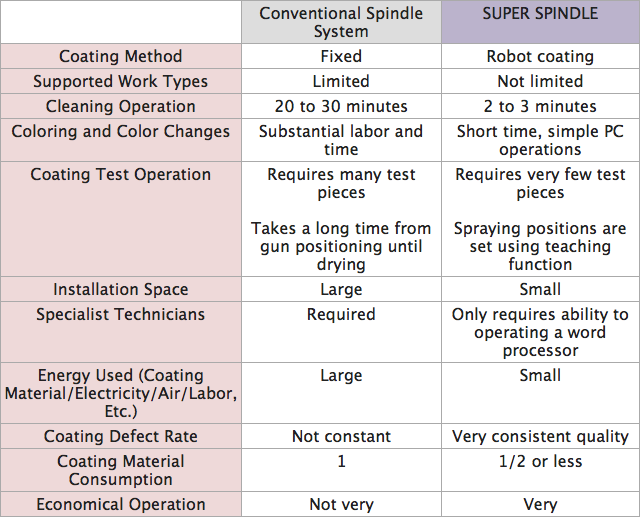

Differences from Conventional Spindle Systems

Ability to Store Coating Data

Condition settings such spray pressure, atomization pressure, and pattern pressure can be entered and checked on the PC monitor in the controller.

Coating Material Management

The controller can be used to make settings for a coating material supply unit as well.

Easy Color and Setup Changes

The compact, simple design with a linked coating material supply unit allows quick cleanup.

Reduced Coating Material Costs

Costs related to the coating material and cleaning solvent consumption volume are reduced substantially.

Spraying Using Ceiling-Suspended Robots

The automatic guns are controlled by the robot system, simplifying operations from coating tests through cleaning and color changes.

Linkage of Robot System, OIL BOOTH, and Sludge Collection System

The automated system improves operating efficiency and makes the work environment more pleasant while greatly reducing costs associated with industrial waste.

Mounting of Work on Circular Custom Jigs and Individual-Jig Clockwise or Counterclockwise Rotating Coating

Ten work pieces can be mounted on each jig.

The jigs rotate clockwise or counterclockwise at a constant speed. Since coating proceeds using two jigs (two-gun configuration) or three jigs (three-gun configuration) at once, a high level of efficiency is maintained. It is also possible to use a more compact conveyor system.

Suitable for both batch systems and manual systems.

Features

- Coating System with Numeric Control

- Substantially Reduced Coating Material Consumption

- Lower Coating Defect Rate

- Excellent Color Expression

- Easy Cleaning and Color Changes

- Easy to Operate, No Special Training Required

- Compact Installation Space

- Reduced Overall Energy Consumption

- Special Technicians Not Needed

Functions

Numeric Coating Material Control

The coating material fixed volume supply unit cuts cost by supplying coating material precisely and without waste.

Quick Gun Setup

Gun mounting, settings, and color changes are quick and easy.

High-Grade Results When Applying Multiple Thin Layers

Variables such as pattern air, atomization air, and outflow volume can be set and changed as needed.

Reduced Overall Energy Costs

Requires only minimal personnel, sharply reduces coating defects, lowers air consumption, reduces coating material consumption, and improves coating efficiency, resulting in dramatically reduced overall energy costs.

Support for System Upgrades

System upgrades from batch to automated system or the addition of color-change or automatic cleaning functions are supported.

Environmentally Compliant Coating System

Improves the work environment while reducing industrial waste. This is an environmentally friendly coating system.

Differences Between SUPER SPINDLE System and Conventional Spindle System