Compare with(Teaching assistant.)

Robot software developed for coating only

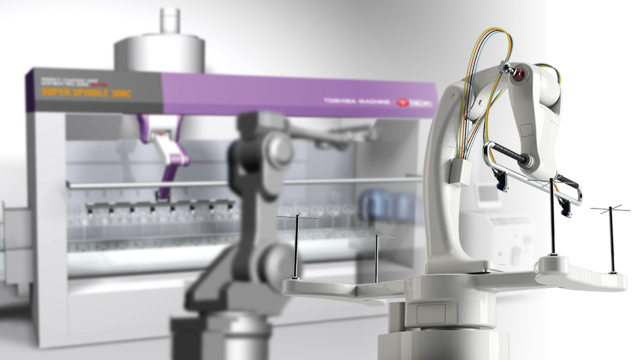

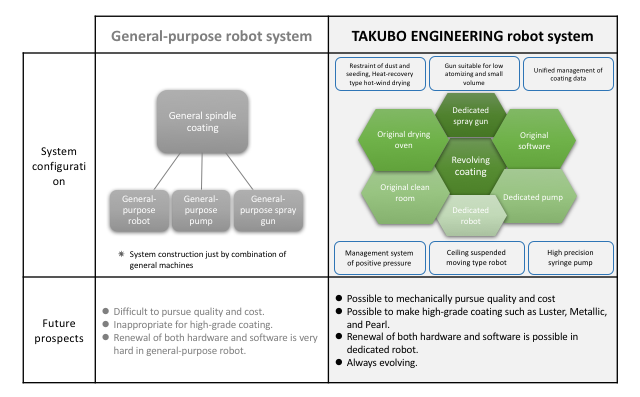

Difference between other companies’ coating robots and TAKUBO ENGINEERING coating robots is difference between general-purpose robots and dedicated coating robots. In general, general-purpose robot is customized to use for coating so that it is not possible to solve the issues of paint consumption and coating cost reduction or to pursue coating film performance and thickness at the same time.In case of TAKUBO ENGINEERING robots such as SOFTBOY series, LINE DANCER and SWAN, all equipment including peripheral devices is systemized so that it is possible to pursue important various kinds of coating requirement by high-grade control with the original teaching software.

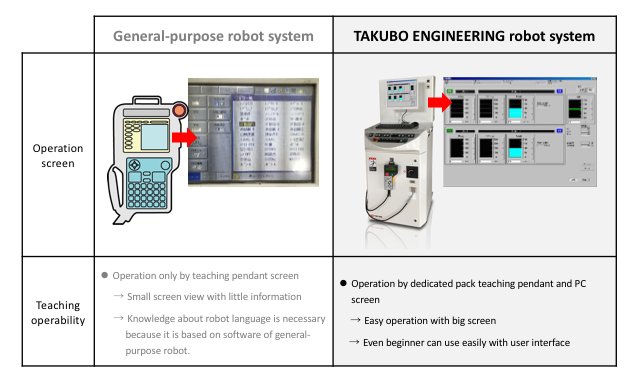

Comparison of robot operation screen

General-purpose coating robot

- Poor operability because of only teaching pendant

Comparison of operating environment - Lack of workability in editing and modification because of small setting screen

TAKUBO ENGINEERING coating robot

- Great operability and higher workability because of use of both teaching pendant and PC screen

Use of both teaching pendant and PC screen - Possible to operate in looking at PC screen

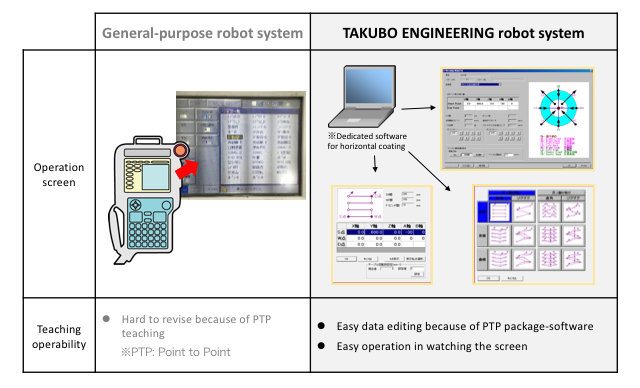

Comparison of robot teaching operability

General-purpose coating robot

- Difficult workability to edit and modify because of PTP teaching

- Expert knowledge such as robot language is necessary in order to operate the robot

TAKUBO ENGINEERING coating robot

- Higher coating workability with easy data editing and modification because of PTP package-software

- Dedicated pack teaching software never requires any expert knowledge such as robot language

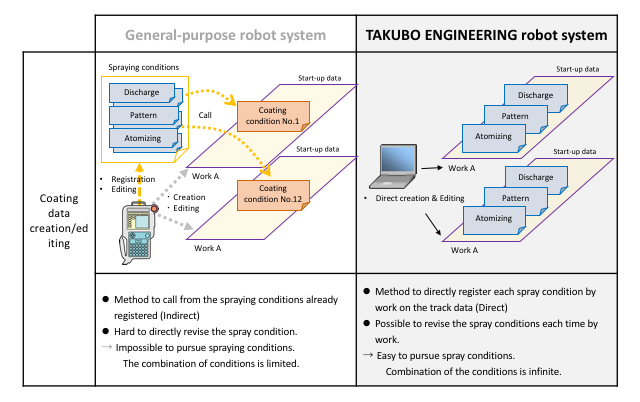

Comparison of coating data creation and editing

General-purpose coating robot

- Regarding registration of coating conditions such as spraying condition, it is not easy because you must register each time you set it up.

- When you want to edit the teaching data, it is very troublesome because you must call and save it each time you create revised data.

TAKUBO ENGINEERING coating robot

- Higher workability because you can directly register each spraying condition into track data

Coating data creation and editing - Possible to edit and revise the data sensually and intuitively

- Possible to pursue high-grade coating film in exhibiting and extracting the paint performance more than enough

- 無駄な塗料使用量の削減に大きく貢献する。

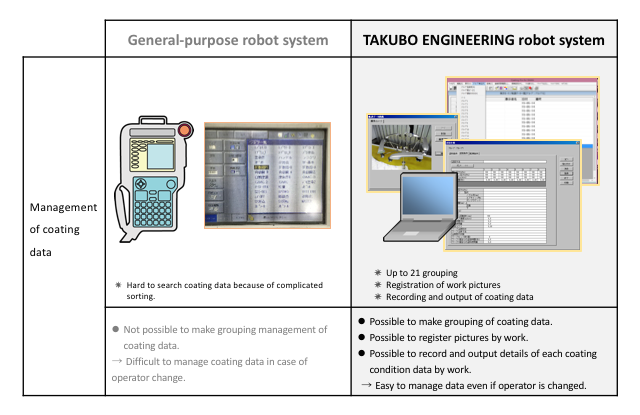

Comparison of coating data management

General-purpose coating robot

- Every time you paint, the painting data is accumulated without any grouping.

- Hard to manage the coating data.

TAKUBO ENGINEERING coating robot

- Easy to search and call the data with good workability because of the coating data list and grouping.

- Possible to save picture and image by work component for data management. Easy to manage as history.

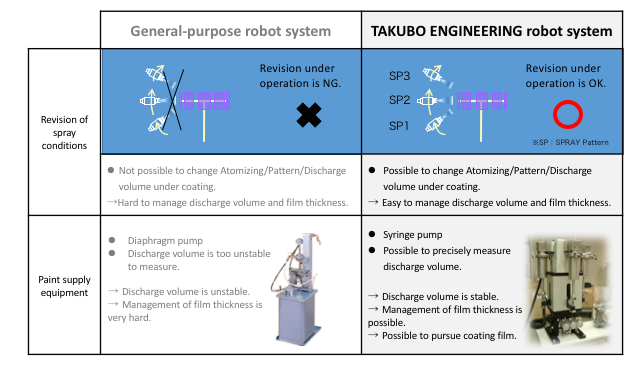

Comparison of spray-condition revision and paint-supply device

General-purpose coating robot

- Basically paint pump is another order. Additional programing is separately necessary to control the pump.

- Diaphragm pump : Pumped by the air-driven pump, so there must be a pulsation. Impossible to control paint volume by 1 cc unit.

- Gear pump : Suitable to supply high viscosity paint. Hard to control by 1 cc unit.

TAKUBO ENGINEERING coating robot

- Pump is already attached on the robot and also connected in control between them.

Explosion-proof type Syringe pump - Syringe pump : Possible to control by 1 cc unit. Supplying paint precisely receiving signals from the robot.

- Possible to reduce waste paint consumption.

- One set of robot and pump realizes Visualization of paint.

Comparison of coating system

General-purpose coating robot

- Unstable coating because of gathering-up of multi-purpose products

- Not possible to make an engineering construction

- Not possible to take unified management of coating film development adapted to the era, countermeasures of cost and environmental issues.

- Small coating production volume because one robot has only few loading spray guns.

TAKUBO ENGINEERING coating robot

- All of the peripheral equipment is connected by high-grade control and thoughts of coating production.

LINE DANCER & DRAGON LINE - Possible to instantly respond to the requirement of new paint or coating films adapted to the era.

- Lots of loading spray guns.

- Coating production volume per one robot is big, and also it has a large production adjustment range.

Options / Related Products

A Pub. Date: May 19, 2017