DRY TEC Medium-sized Drying oven GO-2018S(DRY TEC)

Indirect heating method Exhaust heat recovery type Hot air-drying oven

Medium-sized drying oven DRY TEC single door type Batch production compatible

Single-door type medium-sized drying oven for multi-size coating workpieces DRY TEC Batch type drying oven.

The size (inner dimensions) is W 2,000 mm x D 1,745 mm x H 2,065 mm. The indirect heating method that separates the combustion chamber and the inside of the drying oven is adopted. It is an exhaust heat recovery type hot air-drying oven that supports baking and drying of small to various sizes of workpieces.

DRY TEC Medium-sized Drying oven GO-2018S

- Single-door type hot air-drying oven that can handle multiple items from small to large workpieces.

- Supports low / medium / high temperature drying.

Low (60-100 ℃) High (80-200 ℃) realizes almighty drying. - The inner and outer panels have a panel structure with SPC 0.8mm and 50mm glass wool insulation, which makes installation work easy.

- High safety and quality are made possible by DRY TEC.

Feature

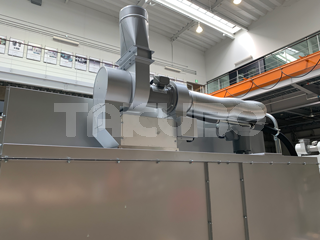

Heat exchanger system

The heat energy to be exhausted is recovered and exchanged with the fresh outside air to be taken in to reuse the energy.The heat exchange rate at that time is ※ 1 (about 85%). This low fuel consumption leads to reduction of drying cost and coating cost.

※1 Heat exchange rate

Ratio of temperature difference in exhaust process to burner combustion gas temperature: (380 ° C-60 ° C) / 380 ° C x 100 ≒ 85

Air supply filter

Purifying with a filter so that floating dust does not enter the combustion chamber and drying oven. Eliminating the factors of dusts, takes in fresh air, and brings out the safety and coating performance by the heat exchange system.

Combustion chamber

Uses an indirect heating method that separates the combustion chamber and the inside of the drying oven. Since the fire does not enter the inside of drying oven, it does not interfere with the gas and high safety can be obtained. In addition, gas checking, fog, and uneven gloss are less likely to occur.

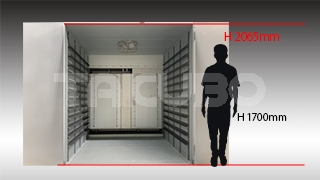

Inside view

With a bottom plate thickness of 3.2 mm, the dolly can be taken in and out smoothly and easily.

※Optional shelf mounting is possible. Size (inner dimensions) W 2,000 mm x D 1,745 mm x H 2,065 mm

Special specifications Custom order

Custom order: Shelf stage 150 pitch, 12 stage specifications

By installing shelves, it is possible to dry paint in a wide range of applications. Supports a variety of workpieces, from small to large, complex in shape, large and small in quantity. It can be customized according to your needs.

Size and drawing

Dimensions: Inner / Outer dimensions

| Dimensions | 2000 mm × 1745 mm × 2065 mm |

|---|

Specifications

DRY TEC Middle-sized drying oven GO-2018S

| Burner | 16 model high and low temperature spark type automatic ignition 1 unit | |

|---|---|---|

| Heat Exchanger | 4mm 1 unit | |

| Circulation Fan | 0.4kW 1 unit | |

| Fan in the oven | 0.4kW 1 unit | |

| Intake/Exhaust Fan | 0.25kW 1 unit | |

| Calorific Value | 35,000 kcal/h x 1 | |

| Fuel | LPG 24.000 kcal/m3 | |

| Power Voltage | 3∅ AC200V 60Hz 1,05 kW | |

| Internal Dimensions | W:2,000mm x D:1,745mm x H:2,065mm | |

| Internal/External Plates | SPC 0.8t (Outer panel metallic silver baking finish) | |

| Insulation | 50t G.W 24kg/m3 | |

| Doors | Double door | |

| Floor | 3.2t steel plate (with bottom insulation) | |

| Temp range | 80~200℃ | |

| Time of temp rising | 30~40min/200℃ | |

| Temp Control Method | ON-OFF type (sensor: K type thermocouple) | |

| Safety Device | Flame monitoring device, overheat prevention device, air flow switch, burner overheat prevention device, and motor overload protection | |

| Options | Custom-made shelves 150 pitches 12 steps |