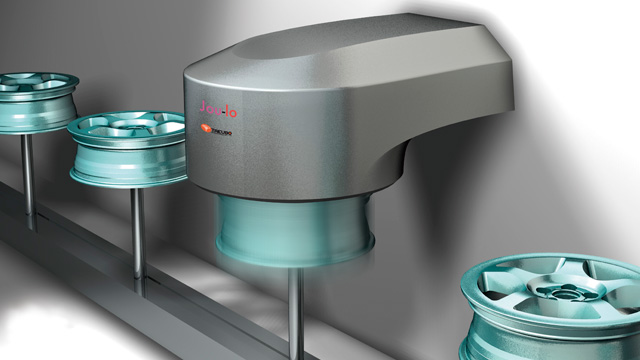

Jou-lo

IH Induction Heating Drying System

Coating-drying system by Induction Heating using electricity, which can provide a short –time drying at high temperature, shortening of baking time, and miniaturization of facilities.

The conventional baking oven is a system that heats the inside of the oven and makes the work pieces dry by hot air using gas. Jou-lo drying system is an induction heating drying, that makes coating layers dry from the inside of the work pieces heating the basic metals by generating magnetic force with the coils. This is the same principle as that of IH cooking heater, which heats metal materials such as frying pan and kettle.

Principle of the drying

There is no energy loss that is necessary in heating the air with the conventional baking oven, because Jou-lo does not have a combustion chamber and even an idea of furnace. Therefore, the drying facility can be miniaturized. Short –time drying at high temperature in coat baking can be also realized by action of the high-speed heating that is a feature of induction heating.

Short time drying

Comparison of drying time for aluminum wheels Example

Example of Aluminum Wheel Drying

*The heating times and efficiencies are different depending on the metals because the resistance values are different. Therefore, some prior tests and design of the coil to meet the shape of work are necessary in order to outbreak the most efficient magnetic force lines.

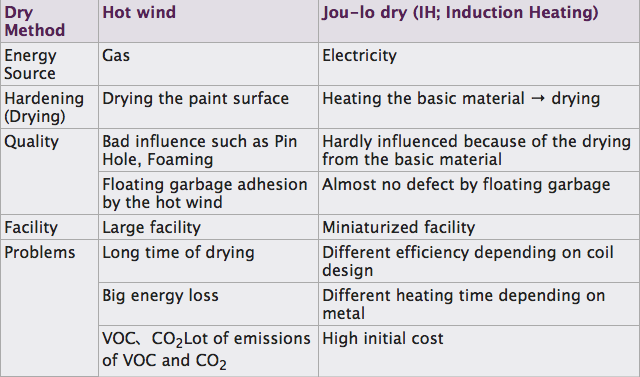

Comparison between baking by hot wind (Camel Back Oven) and drying by Jou-lo

Object work: Automotive wheels

*The data of drying time and others are in our company’s test

*Reduction values and so on are not guaranteed.

*IH Jou-lo sometimes needs prior tests and specific design of the coil for drying efficiency.