Coating Systems

Coating Systems

Lineup

In. Mirror Coating System

Indium Paint Eco Mirror 49

Indium Paint Eco Mirror 49 Realize indium coating film R Technology

Realize indium coating film R Technology Coating System Variations

Coating System Variations Supported workpiece

Supported workpiece Color Variation

Color Variation ECO MIRROR 49 Specifications

ECO MIRROR 49 Specifications

In. Mirror Coating System Q&A

Regarding the equipment for indium coating

Regarding the equipment for indium coating Regarding indium paint

Regarding indium paint Regarding Indium paint in general

Regarding Indium paint in general Regarding indium coating

Regarding indium coating

Jet Line

Outside Door Mirror

Outside Mirror

Outside Mirror Door Mirror 1R2C e.g.

Door Mirror 1R2C e.g. Coating Robot System for Outside Mirrors

Coating Robot System for Outside Mirrors 3 coatings produced by only 1 robot

3 coatings produced by only 1 robot Rotation jig for outside mirror coating

Rotation jig for outside mirror coating High grade coating technology, R-technology

High grade coating technology, R-technology

Mobile Phone

Note PC

Automotive Wheels

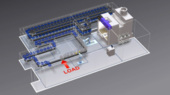

《Concept of Coating System》

Line production coating system

Other Coating Systems.

Technical documentation

Concept of improving coating film quality

Concept of improving coating film quality Pursuit of running costs

Pursuit of running costs Pursuit of revolving coating

Pursuit of revolving coating Indium mirror coating system

Indium mirror coating system

Coating System Q&A

“Spindle coating” is still the most widely used approach to mass production coating, even today. However, this type of coating system has a lot of serious problems in terms of coating efficiency, coating material consumption costs, required coating equipment, operating efficiency, and overall energy costs. The SOFTBOY PRO SUPER SPINDLE coating system employs coating robots and was developed specifically for coating mobile communications devices such as mobile phone handsets. It is a completely new type of system that provides reduced overall energy costs and excellent expandability.

R05T Automatic Gun and PRO POWER JOINT

R05T Automatic Gun and PRO POWER JOINT

Low-Pressure, High-Atomization Automatic Gun。 The PRO POWER JOINT attachment allows multiple guns to be mounted at the end of the Pro Arm. This makes it possible to double or triple the production volume.

Pro Arm

Pro Arm

In addition to the standard 1,400 mm horizontal shaft stroke, extension up to 6,000 mm is supported.

OIL BOOTH

OIL BOOTH

OIL BOOTH provides quiet operation (68 dB) and an extended service life of more than 30 years. It is compatible with semi-permanent oil types.

BOSS2000 (Sludge Solidification Processor)

BOSS2000 (Sludge Solidification Processor)

Solidifies coating sludge into small pellets using centrifugal force of approximately 1,600 G and returns clean oil to OIL BOOTH. Solidifying sludge substantially reduces waste disposal costs.

Pro Control Panel

Pro Control Panel

The control block employs a standard factory-specification PC.

The Deka-Nuri Pack custom software supports teaching in a minimal amount of time. The system stores all the settings, including teaching data, coating conditions (spray volume, atomizing pressure, pattern pressure), work name, production date, and production volume. These saved settings can be distributed easily by e-mail, etc., and used with any SOFTBOY PRO system anywhere.

The system also controls the SP01exp syringe pump coating supply system. This facilitates precise management of the coating material consumption volume.

Dot Jet Liner 01

Dot Jet Liner 01 Dot Jet Liner 02

Dot Jet Liner 02 Jet Design

Jet Design UV Jet Line

UV Jet Line INK JET Q&A

INK JET Q&A Mobile Phone 3C1R

Mobile Phone 3C1R Mobile Phone 3C3R

Mobile Phone 3C3R Smart Phone 3R3C Example

Smart Phone 3R3C Example Note PC SSP300C

Note PC SSP300C Revolving Coating Test

Revolving Coating Test Automotive Wheel

Automotive Wheel Revolving Coating Test

Revolving Coating Test Concept of Coating System

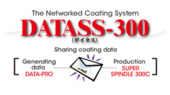

Concept of Coating System DATA-PRO

DATA-PRO Types of DATA-PRO

Types of DATA-PRO Role of the DATA-PRO

Role of the DATA-PRO Quick System

Quick System Dragon Line

Dragon Line Coating robots for System

Coating robots for System Other Coating Systems.

Other Coating Systems. Coating Method/System in general

Coating Method/System in general Others Q&A

Others Q&A