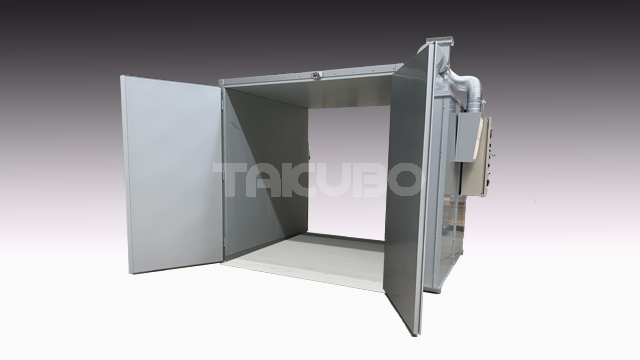

DRY TEC Custom-made products Front and rear door drying oven GOW-2019S(DRY TEC)

Indirect heating method Exhaust heat recovery type Hot air-drying oven

A front and rear door type hot air-drying machine that improves productivity.

DRY TEC Front / rear / both door type medium-sized dryer for batch production

Dedicated Coating drying machine, custom-made, front and rear door type DRY TEC batch production compatible drying oven.

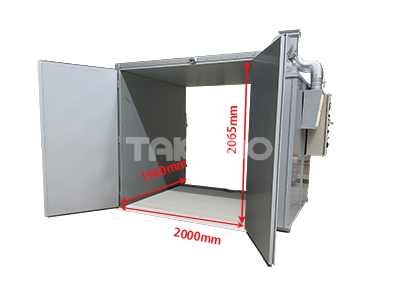

Size (inside dimension) W 2,000 mm × D 1,960 mm × H 2,065 mm

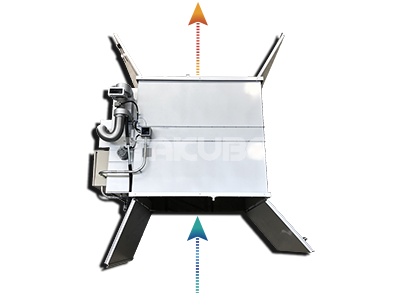

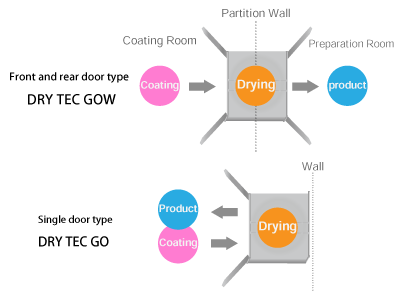

The Front and rear door type is a transit type design. Drying from the clean room (coating) and baking can be taken out from the preparation room to improve work efficiency.

It is a drying machine for coating that can handle workpieces of various sizes such as small to medium and large sizes.

DRY TEC Front / rear / both door type medium-sized dryer GOW-2019S

- The Front and rear door type pass-through medium-sized drying oven secures an internal volume of 8.0 m3 and can be used in any work size.

- Achieves drying with low temperature drying (80-100 °C).

- Our unique heat exchange system realizes constant temperature inside the furnace and energy saving.

Feature

Improved work efficiency Front and rear door type

Compared to the single-door type, the passing type can efficiently increase production work from the coating room to the drying and preparation room. Since the DRY TEC Front and rear door type can be installed in a clean room, the work after coating can be dried with DRY TEC in the clean room, and the dried work can be taken out from the preparation room. It is effective for work efficiency, productivity, and measures against defective dust.

Full utilization in the furnace

Production work such as coating, drying, and loading / unloading management can be performed efficiently in one way.

Size (inside dimension) W 2,000 mm × D 1,960 mm × H 2,065 mm

Since the combustion chamber is an indirect type, the inside of the furnace can be fully utilized without waste. In addition, the dolly can be smoothly taken in and out with a bottom plate thickness of 3.2 mm for carrying in and out.

Difference between GO and GOW series

Compared to the conventional GO series, the GOW series has both front and rear doors, so it can be installed between the clean room and the carry-out preparation room. In addition, because it is a passing type, the entrances and exits at the time of loading and unloading are lined up, the work line becomes smooth, and work efficiency and productivity can be improved.

Size and drawing

Dimensions: Inner / Outer dimensions

| Dimensions | 2000 mm × D 1960 mm × H 2065 mm |

|---|

DRY TEC Middle-sized drying oven GOW-2019S

| Burner | 16 model spark type automatic ignition 1 unit | |

|---|---|---|

| Heat Exchanger | 4mm 1 unit | |

| Circulation Fan | 0.4kW 1 unit | |

| Intake/Exhaust Fan | 0.25kW 1unit | |

| Calorific Value | 18,000 kcal/h x 1 | |

| Fuel | LPG 24.000 kcal/m3 | |

| Power Voltage | 3∅ AC200V 60Hz 1,05 kW | |

| Internal Dimensions | W:2,000mm x D:1,960mm x H:2,065mm | |

| Internal/External Plates | SPC 0.8t (Outer panel metallic silver baking finish) | |

| Insulation | 50t G.W 24kg/m3 | |

| Doors | Double door | |

| Floor | 3.2t steel plate (with bottom insulation) | |

| Temp range | 80~100℃ | |

| Time of temp rising | 20min/80℃ | |

| Temp Control Method | ON-OFF type (sensor: K type thermocouple) | |

| Safety Device | Custom-made shelves 150 pitches 12 steps |