SUPER SPINDLE SYSTEM

TAKUBO ANALECTS

[Spindle Coating] is still used as a coating system for mass production in genral.

However, this system has some probelems in coating efficiency of the paint, coating material consumption, facility, operation efficiency, total energy cost and others.

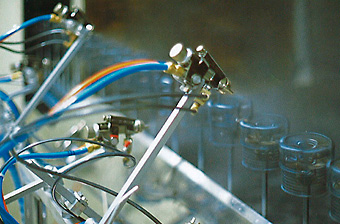

[SUPER SPINDLE SYSTEM]can solve such probelms of the Spindle System, and realize high quality coating by [R-Technology] of Takubo. In this system, the work pieces mounted on circular custom jigs are transported on a coveyor line at a constant speed, and the caoting robots coat them rotating the jigs while fllowing the works in the booth.

Rotating of the works at a high speed on the line, with atomized coating material from the gun, prevents uneven coating and makes it possible to maintain a fixed film thickness. It also provides high production efficiency because the line flow never stops even while coating.

The custom jigs, which are developed to maximize the coating efficiency of the paint, are rotated with multiple work pieces so that the production efficiency per credit hour increases as well.

For example, in case of mobile phone, one jig can be mounted with 10 work pieces, and then the production efficiency will increase very much higher than the conventional spindle coatings, where only one work piece can be coated.

The great features of SUPER SPINDLE SYSTEM are not only high production efficiency but also reduction of coating material consumptions, high quality finish with multi-layer thin film coating, reproducibility by digital control of the coating conditions, and so on.

[Product Information]SUPER SPINDLE

[Product Information]Custom Jigs