Coating Drying System by Induction Heating (IH)

TAKUBO ANALECTS

Takubo is proposing a drying technology with [Idea from 0].

We named IH(Induction Heating)technology[Jou-lo]Technology and introduced it in the metal coating industry in 2007.

There was a hint on the IH cooker used in a domestic kitchen.

[Idea from 0] let us use IH for coating.

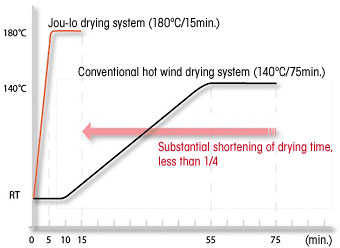

In the conventional metal coating, it is necessary to use camel back oven for a long time at a relatively low temperature. However, Jou-lo Technology completely changes such a common sense.

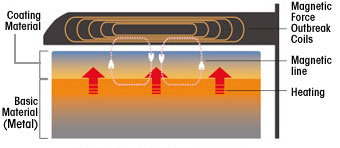

Short time heating from the basic metal material, where coating materials are heated from the inside, provides a high quality drying without any pin holes. This is the most important feature of IH Drying System.

Furthermore,

- Short Time at a High Temperature:High Temperature(180℃〜220℃), Short Time(3 to 5 minutes)

- Possible to control the temperature of the work

- Compatible with any kinds of coating materials for metal drying:Solvent, Powder, Water, and so on

- Miniaturized Facility, Easy Operation:Facility could be miniaturized as well as the operation line could be shortened due to short time drying. It is very useful to VOC measures.

As you can see, the general concept about metal baking caoting will be changed dramatically.

Effects by Introduction of Induction Heating

| Method | Gas Oven | Electrical Oven | IH Oven |

|---|---|---|---|

| Indirect heating by hot air | Self heating of metal basic material | ||

| Heating speed | △ | △ | ◎ |

| Temperature accuracy | △ | ◎ Even heating from the inside for any kinds of shape and material | ○ Possible to heat only the point which you want to do. Not so good to make an even heating by several degrees in case of complicated shaped work. |

| Initial Cost | ◎ | ○ | △ |

| Running Cost | ○ In a short operartion time △ | ○ In a short operartion time △ | ◎ |

| Work Environment | △ | △ | ◎ |

| Operability | △ | △ | ◎ |

| Maintenance | △ Need of brick work | △ Need of heater exchange | ◎ |

| Start Up | △ | △ | ◎ |

| Facility Space | △ | △ | ◎ |

Did you know other drying method for metal coating rather than Camel Back Oven?

Decrease of waste energy provides cost reduction.

It is good for enevironment measures since is is useful for global warming prevention.

Drying by Induction heating...... Now it is an era of ecology in coating.

Takubo also developed a new custom coating material for the new drying system [Jou-lo].

The name is [Jou-lon]。

Thank you very much for your kind attention to this new coating material in advance.