A New Standardized System for Revolving Coating

That Aims to Reduce Costs

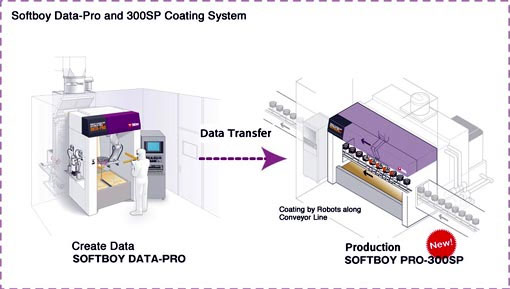

Data-Pro and 300SP System for Coating Mobile Phone Handsets

Rotating the work in this way minimizes coating consumption, makes possible high-quality results (coating film thickness control) with multiple thin coats, and improves efficiency. The new system consists of the Data-Pro and the 300SP.

Data creation operations, including tasks such as teaching and color matching, and the development of custom jigs for the work, can be accomplished without having to stop the production line.

The Softboy Pro series comes with a PC as standard equipment. This allows data of various types to be saved to floppy disk or other storage media. It can then be reproduced exactly on a Softboy Pro system in a different location. This makes it easy to achieve consistent coating quality at multiple plants located in different regions.

Information on settings such as the coating spray volume, atomizing pressure, and pattern pressure is all converted into digital data. In addition, the teaching data, coating and work data, production quantity, coating time, etc., are stored in digital form in precise detail. The power of this technique becomes apparent when reproducing the same effects later on the same Softboy Pro system.