What is the reason why works stop on the conveyor line during coating? (Line Dancer)

Increase of the gun number will enhance the booth width, and also causes a lot of wasting energy by increase of air-volume for supply and exhaust, extremely large booth, and high energy costs.

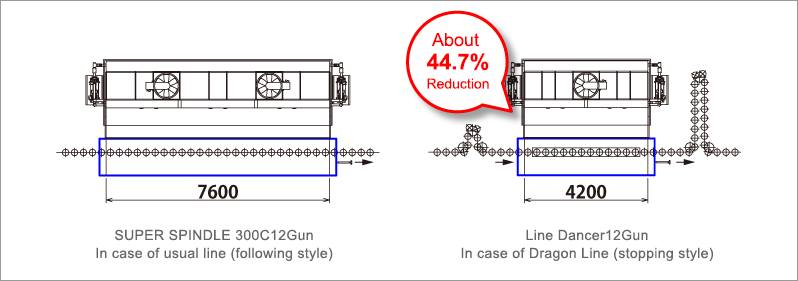

For example, although it depends on size and shape of the work and circle-jig size, the SUPER SPINDLE 300C with 12 guns will need about 7600mm for the booth width. This booth width is based on the condition that the robot has a coating operation while following the conveyor movement.

◎On the other hand, in case of the condition that the robot coats while stopping the work pieces, the designed booth width will be about 4200mm to have the same production.

◎The length of the robot horizontal axis will be shorter.

They are the advantages by coating while stopping.

If your question is not covered in the FAQ, please contact us directly via the Inquiries page.