Coating robots for System

SOFTBOY PRO coating system

Robot system for mass-production is to be installed in a continued conveyor line. The peripheral accessories are also suitable for mass-production so that mass-production with the lowest running-cost are achieved.

SOFTBOY PRO Coating System to win the cost competition

SOFTBOY PRO coating system which TAKUBO ENGINEERING proposes will realize a coating production with low cost, low energy consumption and high efficiency by high-grade control technology with the combination of R-technology, robotic revolving technology (as a core), robot, spray gun, syringe pump the paint supply device, handling device and others.

Features of coating robots for system

The robot can be installed on a continued conveyor line. It is a coating robot system for mass-production to aim the lowest running cost and the great efficiency.

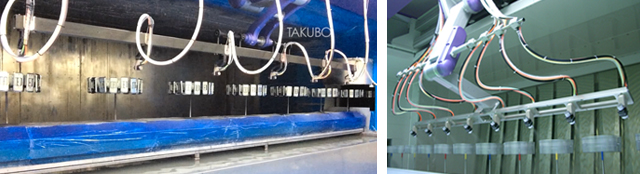

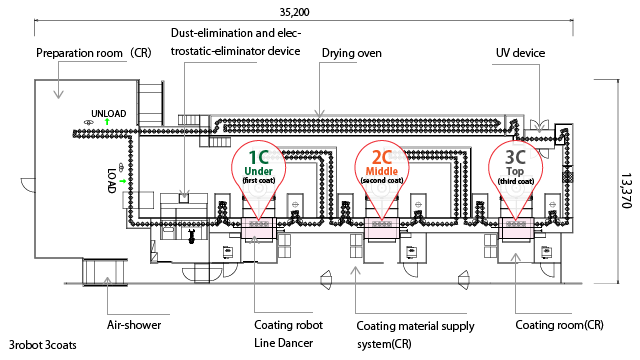

Example of system, 3R3C means 3 coatings by 3 robots

3R3C: 3 robots are managing 1–coat each.

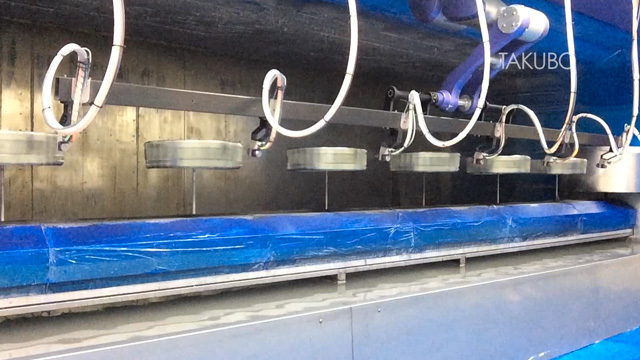

- The coating robot is SOFTBOY PRO M-type Super Spindle 300C or LINE DANCER for use.

- The purposes of this coating system for mass-production are to reduce the paint consumption and to realize a high quality production with a low running cost.

- It is suitable for super-luster coating like Piano touch

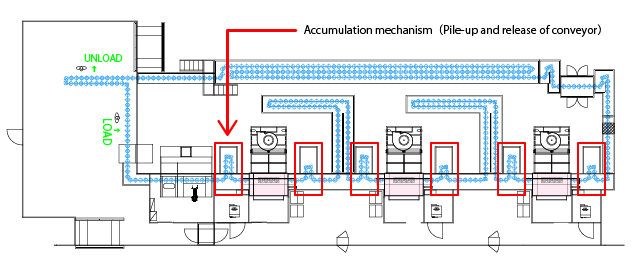

Systematization with DRAGON LINE

DRAGON LINE to reduce energy cost

- Accumulation mechanism set at the both sides of the booth will stop the line only in the booth.

- Stop of the line in the coating booth makes the booth width shorter because the robot does not need to follow.

- Smaller booth causes a much smaller energy cost for air supply/exhaust.

- DRAGON LINE, the conveyor line with the accumulation mechanism will make a big influence on the coating cost.

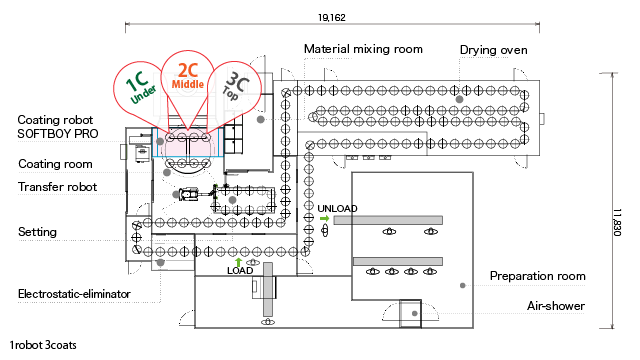

Example of system, 1R3C means 3 coatings by 1 robots

1R3C: System to make a 3-coat production by 1 robot

- In this coating robot, W-turn type with high-accuracy is used for the turn table, and Balance arm type robot is used for the transfer handling. Only one robot can make a 3-coat production while coating and setting repeatedly.

- Adopting the color-change system and the high-speed cleaning system, you can make color-change and cleaning operations very quickly, and also the paint consumption volume becomes the minimum as well as waste cleaning solvent is deleted.

- It is suitable for a coating with multi-kind and small volume production or with a lot of color-change.

- The conveyor line is not polluted by paint because the line is separated from the coating robot.

- Compact coating production facility is realized.

- SOFTBOY PRO W-turn type is a high-versatility robot so that it can be used not only for full- automation system but also for simple-substance as a batch type.