Automatic coating data generation and sharing(SWANIST)

Teaching assistant software

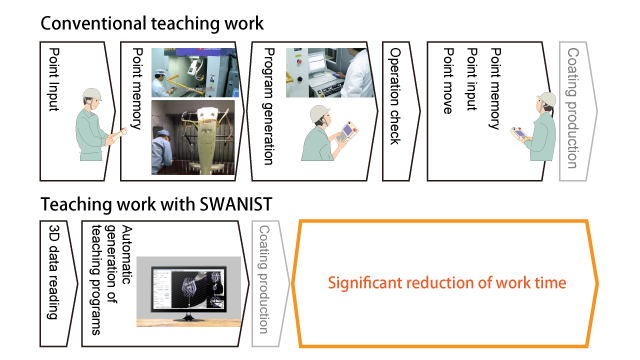

Significant reduction in teaching work Significant improvement in preparation work leading up to coating production

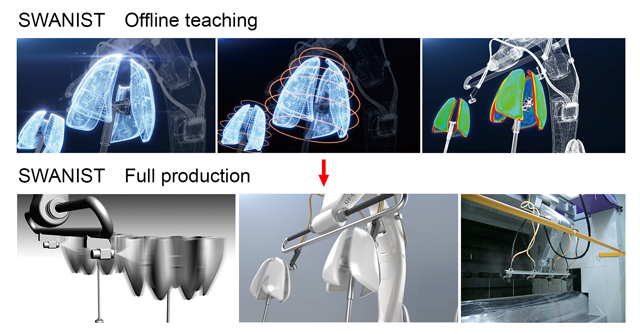

Realization of digital coating

From workpiece data capture to coating simulation, all processes are numerical.

Digitalization of Preparation Processes Leading to Coating Production Coating DX To digital coating

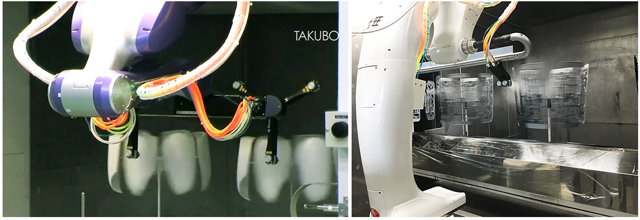

The system has evolved from direct teaching to PTP remote teaching and then to offline teaching. In addition to teaching data, information necessary for coating production, ranging from the setting of coating conditions in coating to workpiece and jig information, will be converted into data. SWANIST creates a new world of offline teaching.

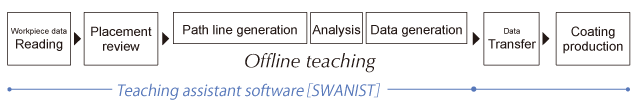

Coating data workflow

Workflow

SWANIST digitizes teaching work, greatly improving the teaching process.

Data generation flow

The generated coating data, including teaching data and condition settings, is transferred to the robot. The production robot can start coating production after simple adjustments.

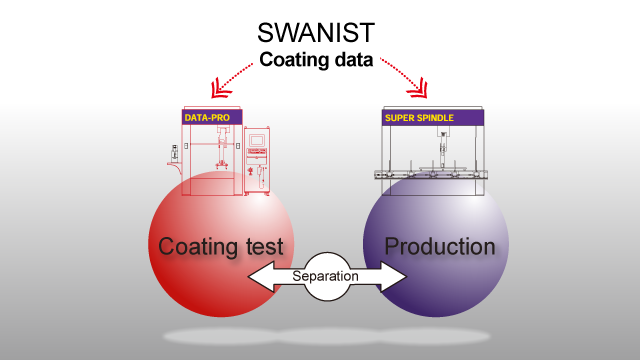

Coating data development and reproduction

To DATA-PRO

Coating data can be transferred to a dedicated robot for coating data creation, and then transferred to the production robot after coating tests.

To SOFTBOY PRO and LINE DANCER (under development)

DATA-PRO will be able to transfer coating data to production robots such as SOFTBOY-PRO, LINE DANCER, and SWAN-PRO.

Full production

Coating data generated by SWANIST can be transferred to the coating robot. Coating production can be started with a simple adjustment of the coating conditions.

Coating data generated by SWANIST can now be shared with any coating robot manufactured by Takubo Engineering, such as LINE DANCER, SWAN Robot, and SOFTBOY DATA-PRO. (Under development)

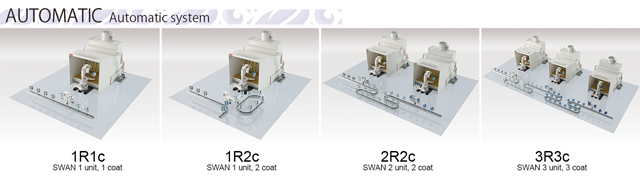

Deployment

Can be deployed on any production line.

Deployment to various production systems

- Deployment in coating systems such as SOFTBOY PRO, LINE DANCER, and SWAN PRO is possible.

- Adaptable from 1 coat to 3 coats, 4 coats, etc.

Coating data can be transferred to coating systems at various plants and sites to maintain the same coating quality with simple condition settings.

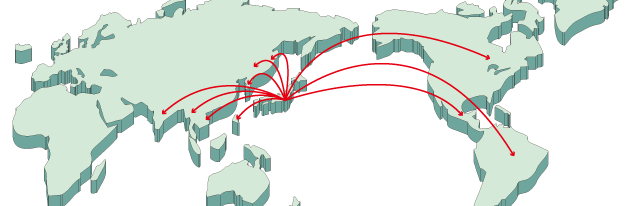

Development to each production site

- By connecting production sites scattered around the country with coating data generated by SWANIST, stable quality and coating costs can be achieved.

- Reduce quality variation.

- Eliminate loss costs.