Jet Line

Ink Jet Coating System

The cost for waste consumption of paint can be reduced substantially. Clients are invited to Graphic Design or Functional Design, where incredible possibilities of coating can be realized beyond imagination.

Lineup

-

Dot Jet Liner 01Jetting system

Inkjet technology to coating technology

System/Emblem coating/maskless coating

Super-accurate application to dents such as emblems Inkjet technology to coating technology. A jetting system that makes the piezo jet head compatible with paint. New technology that brings the wave of digital coating to the coating area

-

Dot Jet Liner 02Keynote

Emblem coating/maskless coating

Inkjet method to coating technology. Revolution of coating technology that can be achieved by making the piezo jet head compatible with paint. Eliminates hidden losses in coating such as paint loss, work loss, and space loss.

-

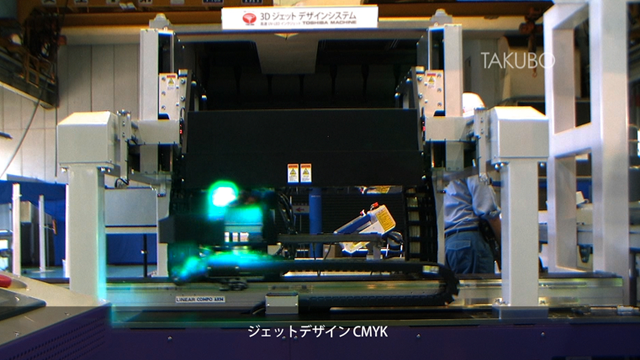

Jet DesignCMYK-UV Jet Design

Ink-jet coating machine

Inkjet coating

High accuracy CMYK-UV Design Machine with high-grade decoration performance and coating film

-

UV Jet Line

UV Coating Machine for Hard-coating

UV coating machine

UV Coating Machine with Low Energy Cost and Low VOC Emission Ink-Jet Head

What is Jet Line?

Jet Line is a new coating system in which Ink-Jet head is modified and systematized for Coating Use. There are two kinds of product line-up by use; No.1 “Jet Design” specialized for Decoration and No.2 “UV Jet Line” for UV Top Coating. Substantial reduction of paint consumption and VOC Cut can be realized, and also environmental performance and quality performance are so much improved with the compact coating system in keeping high accuracy decoration technology of Ink-Jet.

Low Energy Cost and Low VOC Emission

- Consumption volume is only 1/3 to 1/5 of spray coatings

- VOC is cut by more than 90%

High-level Drawing Performance and Coating Film Quality

- High Accuracy and High Drawing Performance

- Special Ink, “Jet-lon”, has the same hardness and quality as spray coatings

Compact

- Large booth or handling device etc for spray coatings is not required. It is a very compact design with the dimensions of H1500×W900×D2000mm or less.

- Automatic system can be constructed in connection with molding lines.

Jet Line has two types by use;

【Jet Design】High accuracy CMYK-UV Design Machine with High-level Drawing Performance and Coating Film Quality

Jet Design is a revolutionary coating system to realize a high-speed decoration loading LED-UV Lamp on the CMYK head. Substantial reduction of paint consumption and VOC Cut can be realized, and also environmental performance and quality performance are so much improved with the compact coating system.

【UV Jet Line】UV Coating Machine with Low VOC Emission and Low Energy Cost

UV Jet Line is a revolutionary coating system to realize a coating by the original hardener improving an Ink-Jet head for coating use. Substantial reduction of paint consumption and VOC Cut can be realized, and also environmental performance and quality performance are so much improved with the compact coating system.

1. Features of Jet Design

Super High-Speed CMYK-UV Design Coating System

Super High-Speed Drawing

Super High-Speed Drawing can be realized by High-Function System Control with the original Color Head, on which LED-UV Lamp is loaded, and the high accuracy Linear Rail. Speedy Decoration can be realized with the production time which is much shorter than those spent by the conventional Ink-Jet method and Silk Print.

Available to produce only 1 piece

Jet Design is able to produce only 1 piece realizing the super high-speed decoration. After design drawing is installed in the special controller of Jet Design, the digitalized data is sent to the ink-jet head so that it is drawn with a few passing at high speed by the CMYK head.

In-line is possible

No over-spraying and no need of booth. Jet Design is so compact that decoration is realized by required minimum device constitution. Decoration can be done by handling just after molding. If it is set next to an existing molding machine, In-line will be possible. One series of production process from Molding, Decoration to Assembly will be completed in a line.

To the world of no defect due to dust and seeding at all

If work pieces are transferred to the decoration just after the molding process, they have no opportunity that dust and seeding defects occur. Perfect products can be produced if it is set in the clean room with temperature control function. Yield rate can be improved because usual dust adhesion by storing after molding does not exist at all.

2. Features of UV Jet Line

Super Compact UV Coating System for Hard-coating

Compact UV Coating System

- UV Jet Line, special UV machine for Hard-coating, is in charge of top coating. Super Hard-coating can be realized by “Dot-lon V-100”, original UV coating material exclusively for Jet Line. Super Hard-coating can generate an excellent coating film as well as the spray coating does.

- Because the design of line is very compact, you might have some doubt if it is a real UV line. UV production line without collection booth can be realized because of no over-spraying.

- Connecting Jet Design and UV Jet Line can complete a compact production line with a series of molding, decoration, hard-coating, and assembly in order.

Surprisingly low dust/seeding defect rate

Quick UV coating & UV radiation never give any chance of dust and seeding. Production line with storing of half-finished goods will become old-fashioned.

Suitable works

The strongest and highest speed Flat Drawing and Hard-coating

- Smart-phone cover

- Automobile internal parts

- Circuit board

- Other coating or drawing on the flat faces

- Drawing on a very slight uneven surface: Positioning accuracy is very superior to be able to draw on a surface with slight unevenness.

Effective size of works

There are so many kinds of works possible such as buttons, switches, pens, hobby goods, automobile internal/external parts, etc (please contact us).

Use

From one-point marking to wide-range drawing

- Putting a name

- Mark and Logo

- Letters

- As a high-speed marker

- And others in the wide-range use

Release:26.Jun.2014