Movement of DRAGON LINE(DRAGON LINE)

Conveyor Line with Accumulation Mechanism

Aiming the lowest running-cost of coating in the world

Takubo Engineering has developed an original high effective conveyor line in order to improve the revolving coating R-technology with SOFTBOY PRO much more. Accumulation mechanism, in which only the conveyor in front of the robot booth stops in coating, has been developed. Installing the accumulation at the both sides of the coating robot of SOFTBOY PRO on the conveyor line makes it possible.

Roles and Effects of DRAGON LINE

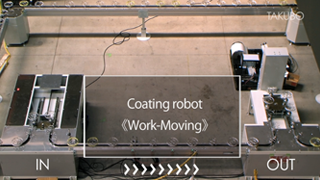

Movement of DRAGON LINE

Usual coating robot is designed to follow continuously moving conveyor line during coating. It is necessary to have a bigger coating area in case of mass-production operation. In result, you need to make a wider coating booth.

In our coating robots for mass-production such as LINE DANCER, in which one robot can be mounted with multiple guns, is able to stop the conveyor in the coating booth for a while only in coating so that the booth can be compact and also air-conditioning cost can be reduced.

Stopping the line for a while means to improve the mass-production efficiency in decreasing the running-cost.

Layout

Two accumulation mechanisms are arranged at the both (right and left) sides of the coating robot (coating booth) on the conveyor line.

Flow

- When the coating starts, the accumulation on the left side starts pilling up, and on the other hand the accumulation on the right side starts releasing simultaneously.

- After the coating is finished, the pilled accumulation on the left side is released with high speed, and the accumulation on the right side starts pilling up with high speed simultaneously.

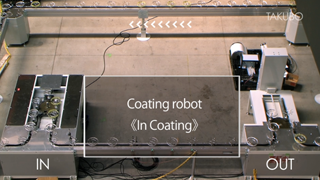

Coating in stopping the line

In the revolving coating, R-technology, work pieces are coated while the circle-jigs mounted with the work pieces are rotated clockwise and counter-clockwise. Stopping the work pieces loaded on the conveyor line in front of the robot booth (in coating) creates high-grade coating performance with the revolving coating.

Why stopping the line?

- Quality in the revolving coating is much more improved by stopping the line.

- “Slow Coating with Quick Finish”, careful finishing is an idea of the TAKUBO’s original coating-theories with R-technology.

Why accumulation mechanism?

- Setting two accumulation (pilling) mechanisms at both sides of the robot makes it possible to stop only the line in front of the coating booth.

- In case of the coating robot with the maximized gun-number such as SUPER SPINDLE 300C and LINE DANCER, which are suitable for mass-production, the booth width will be much shorter than that of the usual booth.

Reduction of Energy Cost

Smaller coating booth is able to reduce its air-conditioning cost substantially.

Realizing Mass-production with Low Cost

Total cost including air-conditioning cost increases in proportion to target production volume. DRAGON LINE can realize mass-production without any increase of the booth size because the accumulation mechanism stops the line in front of the booth.

Suitable Robots and Works

Suitable Robots SOFTBOY PRO Series

- LINE DANCER: from 4-gun to 8-gun (8×2gun)

- SUPER SPINDLE 300C: from 4-gun to 8-gun

Suitable Works

Small parts: Automotive parts related, Mobile telecommunication parts, Smart phones, Mobile phones, and so on

Options / Related Products

Coating RobotLink to product page

Only for Passing-type Robots without Turn tables